介绍

Now, the most common LED显示屏 is the full-color LED display. Do you know how many colours a full-colour LED display can display?

There are tens of thousands of colours. Among so many colours, sometimes the colour of your LED display may shift, so you need to perform colour correction.

1. What is LED display colour calibration?

Colour calibration, in simple terms, is to adjust the LED display so that the colour it displays is more in line with our expected or standard colour output. This process is like “adjusting the colour” of the display.

Use professional instruments to measure the colour of various parts of the screen and then adjust the ratio of the three primary colours RGB (red, green, and blue) through software to ensure that the display can accurately restore the colour in the original image or video.

Colour calibration is really important for LED displays. It is related to our visual enjoyment, the accuracy of information transmission, and the shaping of brand image:

1). Improve visual experience:

Color calibration can make the color of the LED display look more uniform and accurate, without the feeling of bright and dark patches or strange colors.

In this way, when we look at the screen, our eyes will be more comfortable, and the visual experience will naturally improve.

Whether it is watching advertisements, 阶段 performances, or commercial displays, a screen with bright and accurate colors will always attract our attention.

2). Ensure the accuracy of information transmission:

Some industries, such as medical imaging and fashion design, have particularly high requirements for colour. Whether the colour is accurate or not may directly affect the doctor’s diagnosis or the effect of the designer’s work.

Colour calibration can ensure that the LED display accurately restores the colour in the original image or video to avoid misunderstanding or misjudgment due to colour deviation.

The same is true for news broadcasts and conference presentations. Only when the colour is accurate can the information be accurately transmitted.

3). Create a good brand image:

Colour is part of the brand image. Color calibration allows the LED display to display the brand’s standard color at different times and in different environments, so that the brand image is more unified and professional.

When customers see such a screen, their trust and favorability in the brand will naturally increase.

4). Avoid the negative effects of colour deviation:

Color deviation is not a trivial matter. Looking at a screen with inaccurate colour for a long time will make your eyes tired and may even cause a headache. In situations where accurate colours are required, colour deviation may lead to big mistakes.

For example, in medical imaging, inaccurate colours may mislead doctors and affect diagnosis. In addition, screens with inaccurate colours may greatly reduce the brand image, making people feel unprofessional and unreliable.

Just like in the field of medical imaging, if the color of the display is inaccurate, doctors may misread the film and misdiagnose the patient. This is not only bad for the patient, but also affects the reputation of the hospital.

Therefore, colour calibration is really important in the field of medical imaging, which has particularly high requirements for colour.

In general, colour calibration makes us feel more comfortable when looking at the screen, transmits information more accurately, and has a more professional brand image. When you choose an LED display in the future, don’t forget to check whether it has been colour-calibrated!

2. Analysis of the causes of colour deviation of LED displays

1). Aging factors of LED lamp beads

LED lamp beads, like us humans, will slowly “age” over time. This ageing is not visible all at once but gradually appears.

The luminous materials or structures in LED lamp beads will be worn out due to various physical and chemical reactions during long-term use, resulting in a gradual decrease in luminous efficiency.

Just like our vision deteriorates as we age, the brightness of LED lamp beads will gradually dim. At the same time, its colour characteristics may also change.

For example, the original bright red may slowly become a little orange-yellow. This is the change of colour coordinates.

Imagine that the red LED night light in your home that has been used for several years now looks less red and a little orange? This is a typical manifestation of LED ageing.

Although there is no fixed standard for how the colour of each LED lamp changes after ageing, according to experience, generally speaking, LED displays that have been used for 3 to 5 years will begin to show obvious colour shifts.

Some lamp beads may drop in brightness very quickly, and some colours become particularly obvious. These are all normal ageing phenomena.

2). Influence of environmental factors

2.1). Influence of temperature:

The temperature has a great impact on the colour of LED displays. Did you know that LED lamp beads are actually very afraid of heat? If it is too hot, it will “strike” or “be lazy”. In a high-temperature environment, the luminous efficiency of LED lamp beads will decrease, and the colour may also change.

For example, red LEDs may be more likely to turn orange at high temperatures because high temperatures will change the molecular structure of the luminescent material, resulting in a colour shift of the emitted light.

2.2). Humidity effect:

High humidity is not good for LED displays. Did you know that the electronic components in LED displays are very delicate, and they are afraid of moisture? If they are in a high-humidity environment for a long time, the electronic components may be damp, corroded or short-circuited, causing the display to malfunction.

Although the direct effect of humidity on colour change is not so obvious, a long-term humid environment will definitely accelerate the ageing process of the LED display and indirectly affect colour accuracy.

2.3). Light effect:

Strong light, especially sunlight, is a big enemy for LED displays. The ultraviolet rays and strong light in the sun will accelerate the ageing process of the LED lamp bead encapsulation glue, making the glue yellow and brittle.

In this way, the light emitted by the LED lamp beads will pass through the yellowed glue, and the colour will look wrong. In addition, strong light shining on the display will produce reflections, which will make people’s eyes blurry and affect the viewing effect.

2.4). Color shift under different environmental conditions:

For outdoor LED displays, it is hot and humid in summer, and the sunlight is particularly strong. These environmental factors will accelerate the ageing process of the LED, resulting in a greater possibility of colour shift.

Although the indoor LED display screen has better conditions, it will also have colour shift if it is in high temperature, high humidity or strong light environment for a long time.

For example, some LED displays in 购物广场 are close to windows and exposed to sunlight for a long time, so the colour gradually becomes wrong.

3). Control system problem

The colour display of LED display screens is controlled by the control system software. If the software is wrong, the colour of the display screen will definitely be wrong.

For example, the color setting in the software is wrong, or the color temperature is not adjusted correctly, which will cause the color of the display screen to shift.

The whole screen may look warm or cold, or the color of some places is different from that of other places, and there will be spots or color bands.

The hardware part of the control system, such as the control card, data cable, etc., will also cause a colour shift if it is broken. The control card is the “brain” of the display screen, responsible for processing image data and controlling the lighting and extinguishing of LED lamp beads.

If the control card is broken, the data cannot be transmitted or is not transmitted completely, the LED lamp beads may not light up, or the 亮度 is wrong, and the colour will be biased. The data cable is the “bridge” connecting the control card and the LED lamp beads.

If the data cable is broken or has poor contact, it will also cause poor data transmission and affect the colour display.

For example: There is an LED display screen in a shopping mall. After using it for a period of time, customers reported that the color looked wrong and a bit yellowish. The technicians of the shopping mall checked and found that the color temperature in the control system software was set wrong.

The colour temperature was adjusted too high, causing the entire screen to look warm. The technicians quickly adjusted the colour temperature back, and the colour of the display returned to normal.

4). Improper installation and maintenance

The installation angle of the LED display is also very important. If the installation angle is not correct, the viewer may have to tilt his head or raise his head to watch, which is not only uncomfortable, but also affects the color viewing effect.

Because of different viewing angles, the reflection and transmission of light on the display are different, and the colour looks different.

If the display screen is not wiped for a long time, dust and dirt will accumulate on it. This dust and dirt will block the light and make the colour look dark.

In addition, the dirt may contain some chemicals that will corrode the coating on the surface of the display screen or the electronic components inside, causing the display screen to malfunction or color shift.

LED displays for outdoor use must also be windproof, rainproof, and lightning-proof. If the protection is not done well, the display may get wet, damp, or damaged by lightning.

After getting wet or damp, the electronic components in the display will short-circuit or corrode, resulting in an abnormal colour display. If it is damaged by lightning, it will be even more serious, and the entire display may have to be scrapped.

So, when installing an LED display, you must find a professional to install it to ensure that the installation angle is correct and fixed firmly. When using it, wipe the display regularly to keep the surface clean.

Protective measures must also be taken, such as installing a waterproof cover and lightning protection devices for outdoor displays. In this way, the display can be used for a long time and well, and the colour can always be displayed accurately.

3. Does colour correction have to be done by professionals?

Colour correction does not necessarily have to be done by professionals, but it is indeed more reliable to ask them to do it.

If you just want to adjust the color of the photos you took to make them look better, you can use some simple image editing software, such as adjusting the color temperature, saturation, etc., and you can figure it out by yourself.

However, if it involves professional fields, such as filming, printing and publishing, colour correction must be particular. These occasions have particularly high requirements for colour, and the colour must be accurate and cannot change.

At this time, you have to find professionals to help. They use professional software and instruments to adjust the display devices and printers very accurately so that the colours look the same.

Moreover, color correction must consider many factors, such as the color difference of different devices, the influence of light, and how our eyes see colors. These must be carefully considered and processed by professionals to make the color correction the best.

So, although you can try color correction yourself, if you want to pursue higher quality, it is safer to find professionals.

4. Detailed explanation of colour calibration methods and techniques

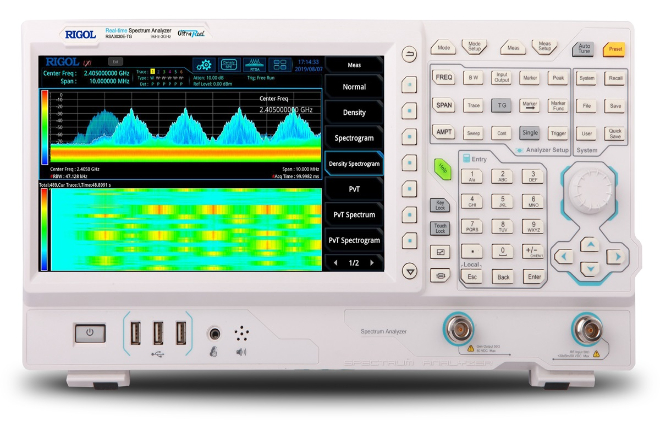

1). Introduction to professional calibration equipment

1.1). Colorimeter

A colourimeter is like a colour detective. It receives the light emitted by the display screen, and then decomposes the light into spectral components of different colors, such as red, green, blue, etc. through internal sensors and algorithms.

Then, it calculates the proportion and intensity of these colour components to derive the overall colour performance of the display screen. In this way, we can know whether the colour of the display screen is accurate.

Using a colourimeter is actually very simple. First, point the colourimeter at the display screen and make sure the distance and angle between them are appropriate.

Then, start the measurement program, and the colorimeter will begin to receive and process the light emitted by the display screen. After the measurement is completed, it will display the measurement results on the screen, such as color temperature, chromaticity coordinates, etc.

We can adjust the colour of the display screen based on this result to make it more in line with our needs.

1.2). Spectrum analyzer

Spectrum analyzer is more advanced and accurate than a colorimeter. It can decompose the light emitted by the display screen into a rainbow-like spectrum, and then measure the intensity and wavelength of each color of light.

In this way, we can know more accurately whether the color of the display is correct and which colors may have deviations.

Using a spectrum analyzer is also relatively simple. Similarly, point the spectrum analyzer at the display and start the measurement program.

It will start to receive and process the light emitted by the display and then display detailed spectral information. We can carefully review this information, find out the colours that may have problems, and then make corresponding adjustments.

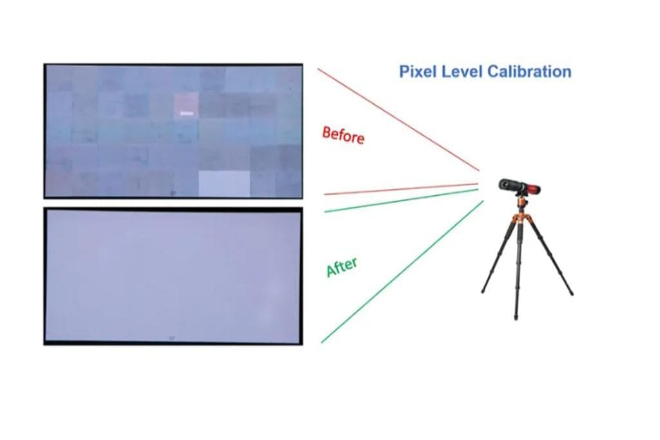

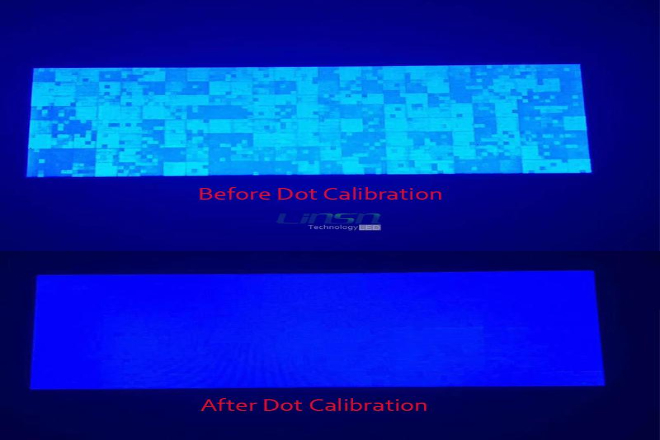

2). Analysis of the colour calibration process

2.1). Preliminary test

First, you need to connect the calibration equipment (such as a colourimeter or spectrum analyzer) to the computer or display. Then, according to the model and specifications of the display, set the test parameters, such as measurement mode, white point setting, etc.

Next, start the test program and let the calibration equipment start measuring the colour of the display. After the measurement is completed, it will generate a detailed test report to tell you how the color performance of the display is.

Before conducting the preliminary test, you need to make sure that the display has been preheated to a stable working state so that the measured results will be more accurate.

At the same time, avoid strong light directly on the display during the test to avoid affecting the measurement results.

2.2). Parameter adjustment

Based on the results of the preliminary test, you can find some colour problems that may exist on the display, such as colour cast and colour difference. At this time, you need to adjust the color parameters of the display.

These parameters include brightness, contrast, colour temperature, etc., which will affect the colour performance of the display. You can adjust these parameters manually or use professional colour management software for automatic adjustment.

When adjusting the parameters, you need to be cautious and do not adjust too much at once to avoid color distortion or exaggeration. At the same time, after adjusting the parameters, we need to wait for a while for the display to stabilize before the next measurement or verification.

2.3). Effect verification

After adjusting the parameters, you need to verify the color effect of the display. At this time, you can put some pictures or videos of standard colors on the display and observe their color performance carefully.

At the same time, you can also compare with the standard color samples to see if the color of the display is consistent with the sample.

When verifying the effect, you need to ensure that the ambient light is stable and moderate, not too bright or too dark, so as not to affect your judgment.

If the verification result finds that there are still problems with the colour, you need to adjust the parameters again until you are satisfied.

5. Why do you need to perform colour calibration regularly?

1). Maintain color consistency

Regular calibration is really important for LED displays. It can keep your large screen consistent in colour for a long time. Did you know that after using the display for a long time, the colour may slowly change due to the ageing of the lamp beads and temperature changes, and it will not look so comfortable?

However, if you regularly give it a “colour checkup” and adjust the parameters, you can keep it as bright and accurate as when you first bought it. Data shows that the colour consistency of a calibrated screen is much better than that of an uncalibrated screen.

Moreover, colour consistency is not only comfortable to look at but also makes our brand image more professional and trustworthy. Therefore, in order to keep the screen beautiful, regular calibration is essential.

2). Adapt to environmental changes

The environment has a great impact on the colour of the display. For example, if the weather is too hot, the colour may become too bright or too dark; if the humidity is too high, the screen may be damp, and the colour will be unstable.

However, if you calibrate regularly, you can adjust the colour of the screen according to environmental changes so that it looks comfortable in any environment.

Of course, in addition to calibration, you can also add a sunshade to the screen or use a constant temperature device so that the environment has less impact on the colour.

3).延长使用寿命

Regular calibration can also help your display screen last longer. After using the screen for a long time, there may be some minor problems, such as a certain point being too bright or the colour being wrong.

If these minor problems are not handled in time, they may become big problems and even make the screen “retire” early. However, if you calibrate regularly, you can find these minor problems in time and fix them so that the screen can be used longer.

Moreover, calibration can also reduce the number and cost of repairs, because the problems are found and solved early, and there is no need to spend a lot of money to repair the big screen.

4). Meet industry standards and customer needs

Some industries, such as advertising, film and television, and medical care, have particularly high requirements for colour. The colour must be accurate so that the audience can see the real thing.

Customers are the same. They want to see bright colours, clear images, and stable performance on the screen. Regular calibration can help you meet these requirements and expectations.

The calibrated screen is accurate in colour, looks comfortable, and customers are satisfied when they see it. Therefore, in order to satisfy both customers and the industry, regular calibration is still necessary.

6. Effect evaluation and maintenance plan after colour calibration

1). Introduction to effect evaluation methods

1.1). Visual inspection:

This is the simplest and most direct way. Just look with your eyes. Before and after calibration, look at the screen more often to see if the colour is more accurate and the image is clearer. Of course, this should be viewed when the light is appropriate, not too bright or too dark.

1.2). Use test patterns:

Find some special test patterns to help. These patterns have various colours and shapes, which can help us see whether the screen colour is accurate and whether there is any colour cast or brightness error.

1.3). Measure color parameters:

Use professional color measurement instruments to measure, such as colorimeters and spectrometers. They can give specific color parameters, such as color temperature and color gamut coverage, so that we can know more clearly how the calibration effect is.

2). Specific operation steps and precautions:

2.1). Visual inspection:

Find someone familiar with the screen and check carefully whether the colour and brightness of each part of the screen are consistent without any other auxiliary tools. Note that you should check it under different lighting conditions to ensure the accuracy of the results.

2.2). Use test patterns:

Put the test pattern on the screen and observe it carefully. Check whether the colour transition is natural and whether there are any breaks or colour bands. Also, whether all colours are accurate and whether there are any deviations.

2.3) Measure color parameters:

When measuring with an instrument, follow the instrument’s instructions to ensure accurate measurements. After the measurement, compare the results with those before calibration to see what has been improved and what needs to be adjusted.

The precaution is that the evaluation should be comprehensive and meticulous, and do not miss any factors that may affect the results. In addition, the evaluation results should be recorded for future reference and comparison.

3). Develop a long-term maintenance plan

Colour calibration is not a one-time job, and it must be done for a long time to ensure that the screen colour is always accurate.

3.1). Regular calibration interval:

This should be determined according to the use of the screen and environmental changes. Generally speaking, calibration once every few months is enough. However, if the screen is used very hard or the environment changes a lot, the calibration interval must be shortened.

3.2). Training of maintenance personnel:

Calibration work must be done by professionals, so maintenance personnel must be trained regularly to let them master the latest calibration techniques and methods.

结论

Looking back on this article, we have deeply explored the importance and necessity of regular colour calibration of LED displays.

Colour calibration is not only a key measure to maintain the colour accuracy of LED displays but also an important means to enhance the visual experience, ensure the accuracy of information transmission, and shape brand image. I hope this article is helpful to you.

最后,如果您想了解更多关于LED显示屏的知识, 请与我们联系。