Introduction

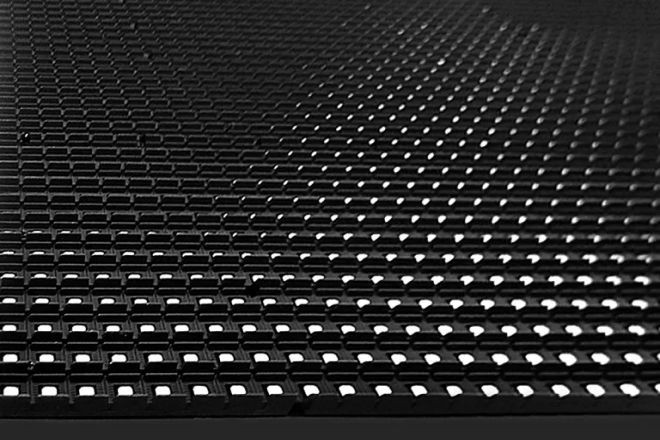

What is the durability of LED display screen? It is a comprehensive indicator used to measure its durability and stability under various conditions of use.

If you want the LED display screen to be more durable, you must pay attention to this indicator. This article will tell you what factors the durability indicator is related to!

1. It is related to the performance of LED display screen components

1). The quality of LED lamp beads:

When we talk about the durability of LED display screens, the quality of LED lamp beads is undoubtedly the primary consideration. Imagine that if the lamp beads are like fragile glass, wouldn’t the entire display screen become a “short-lived ghost”? So, we have to talk about the LED lamp beads.

- Attenuation characteristics:

Attenuation, in simple terms, means that the brightness of LED lamp beads will dim after being used for a long time. This is what we often hear as “light decay.” Just like the battery of your newly bought mobile phone, it can be used for a whole day when fully charged at the beginning, but after a long time, it will run out of power in half a day.

High-quality LED lamp beads will have very small attenuation characteristics, just like those timeless classic songs, which are still so beautiful no matter how many times you listen to them. Behind this is actually a comprehensive reflection of material quality, operating temperature, driving current, and packaging technology.

Good materials, coupled with precise technology, can keep the LED lamp beads stable in brightness during long-term work so that the display screen can consistently present you with a clear picture.

- Water vapor penetration characteristics:

If you put the LED display screen outdoors, it will have to face the test of wind, rain, and a humid environment. At this time, the water vapor penetration characteristics of LED lamp beads are particularly important.

Just like your mobile phone has a waterproof function, LED lamp beads also need to have good sealing performance to resist the intrusion of moisture. Once moisture enters the inside of the lamp beads, it will be troublesome.

At the least, the performance will be reduced, and at the worst, it will be directly damaged. Therefore, the packaging materials and processes of high-quality LED lamp beads will be specially treated to ensure that they can be as stable as old dogs in humid environments.

- Anti-ultraviolet performance:

For LED displays used outdoors, another factor that must be mentioned is anti-ultraviolet performance. Ultraviolet rays are a tough role. They can destroy the phosphor coating and other optical materials inside the LED lamp beads, greatly reducing the life of the lamp beads.

Therefore, high-quality LED lamp beads will use anti-ultraviolet materials and coatings, just like putting on a layer of sunscreen for the lamp beads, so that they can run freely in the outdoor environment without fear of ultraviolet rays.

2). Other key components:

In addition to LED lamp beads, other key components of the display are also important factors affecting durability. For example, the switching power supply is like the heart of the display, providing power for the entire system.

If the quality of the switching power supply is not up to standard, the display may have problems such as unstable voltage and excessive current, thereby damaging other components. Another example is the circuit board, which is a bridge connecting various components.

If the quality of the circuit board is not good, then the signal transmission may have problems, causing the display to not work properly.

Plastic shells and connectors are also parts that cannot be ignored. The plastic shell needs to have good sealing and impact resistance to protect the components inside the display from the external environment.

The connector needs to have good conductivity and plug-in resistance to ensure that the connection between the various components is stable and reliable. Finally, there is the casing, which is not only the appearance of the display but also an important barrier to protect the internal components.

Therefore, when choosing an LED display, you have to consider the quality of these components in all aspects!

2. Related to the production process of LED display

1). Advanced production process

The advanced production process has a vital impact on the performance and life of LED displays, among which fatigue resistance is an important aspect.

Fatigue resistance refers to the LED display screen that can maintain stable display effect and performance under long-term and high-frequency operation.

Advanced production technology can significantly improve the fatigue resistance of LED display screens.

Specific production process links include component storage and pretreatment process, furnace welding process, three-proof treatment process, waterproof sealing process, etc.

- Component storage and pretreatment process:

This link mainly involves the storage and pretreatment of core components such as LED lamp beads and circuit boards. A high-quality storage environment is like providing a comfortable “nest” for components to prevent them from any damage.

The pretreatment process is like giving the components a “full body SPA” to allow them to meet the next challenge in the best condition and improve the welding quality and yield rate.

- Furnace welding process:

This is a key step in welding components to circuit boards. The furnace welding process requires strict control of parameters such as temperature and time to ensure the firmness and reliability of the welding points.

At the same time, advanced welding equipment and processes are also needed to improve welding quality and efficiency.

- Three-proof treatment process:

Three-proof treatment refers to the treatment of core components such as circuit boards to prevent moisture, mildew, and salt spray. This link can significantly improve the weather resistance and reliability of LED display screens, so that they can still maintain stable performance in harsh environments.

- Waterproof sealing process:

For LED display screens used outdoors, the waterproof sealing process is essential. By using special sealing materials and processes, it can ensure that the inside of the display screen is not damaged by moisture and moisture.

It’s like putting on two layers of “protective clothing” for the LED display screen. Whether it is moisture, mildew, or salt spray, it cannot penetrate these two layers of “protective clothing,” ensuring that the display screen can be as stable as Mount Tai in harsh environments.

2). Experience accumulation of manufacturers

Experienced manufacturers usually have stronger control over production processes. This is because they have accumulated rich experience and technical knowledge in long-term production practice and can formulate reasonable production processes and solutions for various complex situations.

Specifically, experienced manufacturers have significant advantages in the following aspects:

- In-depth understanding of component performance:

They know how to select and match components with different performance and specifications to achieve the best display effect and performance.

- Precise control of production process:

They are also very good at controlling production process. No matter which link, they can accurately grasp every detail to ensure the quality of the display screen produced. This precise control of production process is like a skilled “craftsman” who can create exquisite works of art.

- Quick response to quality problems:

Experienced manufacturers can also respond quickly when faced with problems. They are like an experienced “doctor” who can quickly diagnose the root cause of the problem and take effective treatment measures. This ability to respond quickly to quality problems is also one of the important factors to consider when choosing a manufacturer.

3. Related to the use environment of LED display screens

1). Differences between indoor and outdoor

The environment in which LED display screens are used is mainly divided into two categories: indoor and outdoor. There are significant differences between the two, which directly affect the performance, maintenance, and life of the display screen.

- Indoor:

The indoor environment is relatively stable and has little impact on the display screen. Indoor LED displays are usually installed in shopping malls, conference rooms, theaters, gymnasiums, and other environments.

These places usually have small changes in ambient temperature, moderate humidity, and no interference from natural factors such as direct sunlight and rain. Therefore, indoor displays are designed to pay more attention to display effects, such as higher resolution, color saturation, and delicate picture quality, to meet the needs of close viewing.

At the same time, the installation and maintenance of indoor displays are relatively simple and can be installed in a variety of ways, such as wall mounting, hanging, or embedded installation.

- Outdoor:

The outdoor environment is relatively harsh, and factors such as large temperature differences, wind, sun, and rain have a greater impact on the display. Outdoor LED displays need to face challenges such as strong sunlight, rain erosion, large temperature differences, and dust.

In order to meet these challenges, outdoor displays are designed to be more rugged and durable, with good waterproof, dustproof, UV protection, and weather resistance. In addition, the brightness of outdoor displays is usually higher to ensure that they are still clearly visible under direct sunlight.

However, this also brings higher energy consumption and heat dissipation requirements. In terms of maintenance, outdoor displays usually need to adopt front maintenance or rear maintenance designs due to their special installation locations to quickly replace damaged parts.

2). Specific impact of environmental factors

- Temperature:

Temperature is one of the important factors affecting the life of LED display screens. High temperatures will accelerate the aging process of LED lamp beads and shorten their service life.

At the same time, excessively high temperatures will also affect the heat dissipation performance of the display screen, causing the internal temperature to rise, further aggravating the aging of components.

On the contrary, a low-temperature environment may also have adverse effects on the display screen, such as causing the liquid crystal material to freeze and the circuit performance to decline.

Therefore, when using the LED display screen, it should be kept working within a suitable temperature range as much as possible.

- Humidity:

The impact of humidity on LED display screens cannot be ignored. A high humidity environment can easily cause the internal components of the display screen to become damp and corroded, thus causing failures.

This effect is particularly obvious in the rainy season or humid areas. Therefore, when using LED display screens in these environments, effective moisture-proof measures need to be taken, such as installing a dehumidifier and keeping indoor ventilation.

- Dust, particulate matter:

Dust and other particulate matter can also damage LED display screens. Dust deposited on the surface of the display screen will affect its light transmittance and heat dissipation performance, and may also enter the interior of the display screen through the gaps, causing damage to the circuit and components.

Therefore, regular cleaning of the surface and interior of the display screen is one of the important measures to maintain its good performance.

4. About the maintenance of LED display screens

LED display screens are the “star” products in modern life. Whether it is the billboards in shopping malls or the big screens at concerts, they are inseparable from it. However, do you know?

This LED display screen also needs care, just like our skin; regular maintenance is needed to keep it in the best condition.

1). Daily maintenance a small matter, but don’t ignore it

Daily maintenance sounds simple, but there is actually a lot of knowledge in it. You have to “bathe” the display screen regularly and clean up all the dust and dirt. Think about it: the display screen is exposed to the outside every day, to the wind and sun, and it must be easy to get dirty.

This dust not only affects the display effect but may also block the heat dissipation holes and make the display screen “fever.” So, take a soft cloth or a professional cleaning tool, wipe it gently, and the display screen will be brand new.

Also, don’t always let the display screen turn on the maximum brightness. Although high brightness can indeed make the display screen clear even under strong light, if it is on for a long time, the LED lamp beads can’t “stand” it and age faster.

Therefore, we have to adjust the brightness according to the actual situation so as to ensure that it can be seen clearly and not let the lamp beads get too tired.

2). Professional maintenance depends on professionals

Of course, although daily maintenance is simple, real professional maintenance still depends on professionals. They have rich experience and professional skills and can solve those “big problems” that we can’t solve.

For example, the inspection of the power supply line. This power supply line is like the “lifeline” of the display screen. If there is a problem, the display screen will “strike.” Therefore, professionals have to regularly check whether the line connector is loose and whether the line is damaged to ensure that the display screen can work steadily.

Also, deep cleaning of the screen surface. We usually wipe it with a cloth to remove the dust on the surface. But professionals will use professional cleaning agents and tools to clean up those stubborn stains and dirt, so that the display screen can restore its original brilliance.

The most important thing is that once a module on the display screen has a problem, such as not lighting up or the color is wrong, you have to find a professional to repair or replace it quickly.

These modules are like the “parts” of the display screen. If any “part” is broken, the entire display screen will not work. Therefore, timely detection and treatment of problems can ensure the integrity and stability of the display screen.

5. Related to the use of LED display screens

1). Frequency of use of LED display screens

Long-term, uninterrupted use:

Although LED display screens are designed to work continuously for a long time, long-term, uninterrupted use will accelerate the aging process of LED lamp beads.

The luminous efficiency and life of LED lamp beads will be affected to a certain extent under long-term high-load work. Just like people, working overtime and staying up late for a long time will definitely not be able to bear it. The same is true for LED lamp beads.

If they work at a high load for a long time, their aging speed will accelerate, and their life will be shortened. Therefore, if possible, try to avoid letting the display screen work uninterruptedly for a long time.

- Intermittent use or low-load use:

In contrast, intermittent use or low-load use helps to extend the life of the display screen. When the display screen is not needed, it can be turned off or adjusted to low power mode to reduce the working time and load of the LED lamp beads.

For example, when there is no one in the mall at night, you can turn off the display screen; when the concert is over, don’t leave it on all the time. In this way, you can not only extend the life of the display screen but also save a lot of electricity bills!

2). Brightness and current control

- Reasonable brightness setting:

Brightness is one of the important factors affecting the life and energy consumption of LED display screens. Too high brightness will not only accelerate the aging of LED lamp beads but also increase energy consumption. Therefore, the brightness of the display screen should be set reasonably according to the actual environment and usage needs.

For example, in a dark indoor environment, the brightness can be appropriately reduced, while in an outdoor environment with direct sunlight, the brightness needs to be increased to ensure the display effect.

- Current control:

The brightness of the LED is proportional to the current passing through it. When the current increases, the brightness of the LED will also increase; however, if the current is too high, it will also accelerate the aging process of the LED lamp beads.

Therefore, by reasonably controlling the current, the service life of the LED can be extended while ensuring the display effect.

In addition to the above, there are some tips to remember. For example, don’t turn the machine on and off frequently, which can easily impact the power supply system and control system of the display screen, affecting its stability and life.

Regular calibration and updating are also important. Just like our mobile phones need to update the system regularly, LED displays also need to adjust color balance, brightness, contrast, and other parameters regularly, as well as update drivers and firmware. In this way, it can always maintain the best display effect.

Conclusion

In summary, the durability of LED displays is the result of multiple factors. Consumers should consider product performance and durability comprehensively and do a good job of daily maintenance; manufacturers need to continue to innovate and improve product quality.

Finally, if you want to know more about LED displays, please get in touch with us.