Introduction

With the increasing application of LED display screens, the convenience of its maintenance and management has also become the focus of users.

The traditional post-maintenance method, that is, after the display screen is installed, maintenance is performed from the back by dismantling the surrounding structure or using special tools, which often faces challenges such as space limitations, complex operations, and high safety risks.

In this context, pre-installation maintenance of LED display screens has emerged as an innovative solution, which has brought revolutionary changes to the maintenance and management of LED display screens with its easy operation, high efficiency, and safety.

1. Brief introduction to LED display screen maintenance methods

As an important tool for modern information dissemination, the choice of maintenance method directly affects the long-term use effect and maintenance cost of the display screen.

Next, we will analyze in detail the two basic maintenance methods of LED display screens-post maintenance and front maintenance, to help you better understand the differences and applicable scenarios of these two methods.

1). Post-maintenance

Post-maintenance, as the name suggests, means that maintenance personnel need to perform maintenance and repairs from the back of the LED display screen.

This usually means that enough space needs to be reserved behind the display screen so that maintenance personnel can enter and perform necessary operations.

1.1). Features and operation:

High technical requirements: The rear maintenance method often involves complex installation and disassembly processes and requires professional technicians to operate.

Large space occupation: Due to the need to reserve maintenance channels, the rear maintenance method will occupy more installation space, which may be a challenge for indoor or space-limited application sites.

Complex maintenance: During the maintenance process, maintenance personnel may need to disassemble part of the structure or wires, which not only increases the complexity of maintenance but also may prolong the maintenance time.

Application scenario: The rear maintenance method is usually suitable for large outdoor LED displays, such as giant billboards on the exterior walls of buildings. These displays are difficult to maintain from the front due to their large size and high installation position, so rear maintenance becomes a viable option.

1.2). Limitations:

Space limitations: For indoor compact applications or inlaid or wall-mounted structures, the rear maintenance method may not be applicable due to space limitations.

Maintenance cost: Due to the need for professional technicians and complex operation processes, the maintenance cost of the rear maintenance method is relatively high.

2). Front maintenance

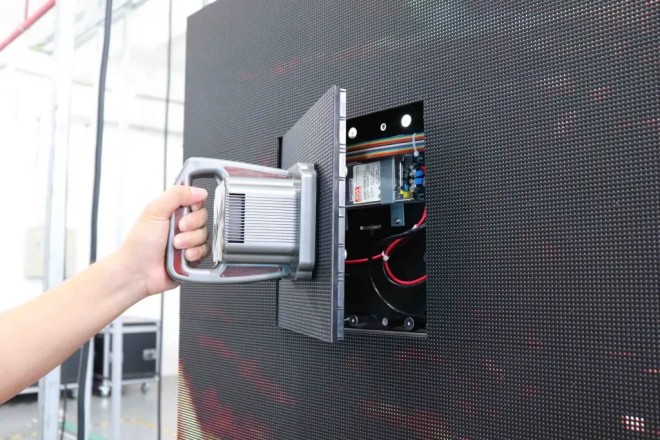

Front maintenance refers to maintenance and repair by maintenance personnel from the front of the LED display. This maintenance method usually uses a cleverly designed fixing method to make the module structure of the display screen easy to remove from the front.

2.1). Features and advantages:

Space saving: The front maintenance method does not require a reserved maintenance channel, which greatly saves installation space. This is a significant advantage for indoor or space-limited application sites.

Easy to operate: The front maintenance method supports the front maintenance of independent modules without disassembling the entire display or wires. This makes the maintenance process simpler and faster.

High safety: Since the operation is performed from the front, the risk of maintenance personnel working at high altitudes or in narrow spaces is reduced. This is crucial to ensure the safety of maintenance personnel.

2.2). Advantage analysis:

Space saving: The front maintenance method can make the overall structure of the display screen more compact and better integrated with the surrounding architectural environment. This is of great significance for improving indoor visual effects and aesthetics.

High maintenance efficiency: In the event of a single-point failure, only one person is required to disassemble and maintain a single LED or pixel. This not only reduces maintenance costs but also shortens maintenance time.

Easy to promote: With the continuous development of LED technology and the rise of small-pitch LED transparent screens, front-maintained indoor LED display products have gradually dominated the market. This is because the front maintenance method has obvious advantages in terms of space-saving, easy operation, and high safety.

Application scenario: The front maintenance method is suitable for various indoor application places, such as shopping malls, hotels, conference rooms, etc. These places usually have high requirements for space utilization and aesthetics, and the front maintenance method can meet these needs well.

2. Analysis of scenarios suitable for installing front maintenance LED display screens

1). Space-constrained environment

Space-constrained environments refer to those areas that are stretched thin in terms of space resources, such as high-rise buildings in the city center, compact shopping mall interiors, small conference rooms, etc.

These environments usually have difficulty accommodating large equipment or complex maintenance processes due to limited space.

1.1). Advantages of front maintenance:

The ingenious design of the front maintenance LED display enables its modules to be easily removed from the front without the need for additional maintenance space.

This is a huge advantage for space-constrained environments. Imagine if the display needs to be maintained from the back, then in a high-rise building or compact shopping mall, this may require the removal of surrounding decorations or structures, or even the construction of scaffolding, which is time-consuming and laborious.

The front maintenance design avoids these troubles, making the maintenance process easier and faster.

1.2). Example analysis:

Suppose a small cafe in the city center wants to install an LED display in the store to display menus and promotions.

Due to limited space in the store, traditional rear maintenance displays may take up a lot of space and even affect the customer experience.

The front maintenance LED display can easily solve this problem. It not only saves space, but also ensures that the maintenance process does not cause any interference to the store environment.

2). Places with high safety requirements

Places with high safety requirements usually refer to those areas with potential safety hazards, such as billboards installed at high altitudes, shopping malls with dense traffic, and monitoring centers in public places.

In these places, the maintenance operations of the equipment must strictly comply with safety regulations to prevent any accidents that may cause casualties or property losses.

2.1). Advantages of front maintenance:

The front maintenance design improves safety by reducing high-altitude operations and simplifying maintenance processes. First, it avoids the risk of maintenance personnel needing to perform complex operations at high altitudes or in narrow spaces.

Second, the front maintenance method supports front maintenance of independent modules, which means that the replacement or repair of a single module will not affect the operation of the entire display, thereby reducing potential safety risks.

2.2). Case analysis:

An advertising company located on the top of a high-rise building plans to install a large LED display screen on the roof to display advertisements. Since the display screen is located at a high altitude, the traditional rear maintenance method may bring great safety hazards to maintenance personnel.

The front maintenance LED display screen can solve this problem well. Its design allows maintenance personnel to perform maintenance operations on the ground or on a safe platform, which greatly reduces safety risks.

3). The need for frequent content replacement or debugging

The need for frequent content replacement or debugging usually comes from places where display content needs to be constantly updated or technical adjustments need to be made, such as billboards, event sites, shopping mall promotion areas, etc.

These places usually need to update the display content according to different activities or needs, so the maintainability and ease of operation of the equipment are particularly important.

3.1). Advantages of front maintenance:

The front maintenance design allows maintenance personnel to easily access the back of the display screen from the front, so as to quickly replace content or technical debugging.

This maintenance method not only saves time costs, but also improves work efficiency. For places where content needs to be frequently changed, the front maintenance LED display screen is undoubtedly an ideal choice.

3.2). Case analysis:

A large shopping mall plans to install multiple LED screens inside the mall to display advertisements and promotions of different brands.

Due to the limited space and dense traffic inside the mall, the traditional rear maintenance method may cause inconvenience to the shopping mall. The front maintenance LED screen can solve this problem well.

Its design allows maintenance personnel to quickly change the display content or perform technical debugging without disturbing the customer’s shopping experience.

4). Areas with high requirements for aesthetics

Areas with high requirements for aesthetics usually refer to places that pay attention to details and overall effects, such as high-end shopping malls, art galleries, museums, etc. These places usually hope that the equipment will not destroy the overall aesthetics of the surrounding environment during operation.

4.1). Advantages of front maintenance:

The front maintenance design uses clever structural design and installation methods to ensure that the display will not destroy the overall aesthetics of the surrounding environment during maintenance.

It avoids the need to open a maintenance channel on the back or side of the display, thereby maintaining the integrity and aesthetics of the display.

In addition, the front maintenance method also supports the front maintenance of independent modules, which means that the replacement or repair of a single module will not have much impact on the overall display effect.

4.2). Case analysis:

A high-end shopping mall plans to install a large LED display inside the mall to display artwork and exhibition information. As the mall’s interior decoration is luxurious and pays attention to details, the traditional post-maintenance method may damage the overall aesthetics of the mall.

The front maintenance LED display can solve this problem. Its design ensures that the display will not damage the mall’s decoration style and overall effect during maintenance, thus meeting the mall’s requirements for aesthetics.

3. Suggestions from technical considerations and selection

1). Introduction to key technical parameters

When selecting a front-maintenance LED display, understanding its key technical parameters is crucial to ensure the performance, reliability, and maintenance convenience of the equipment. The following are some important technical parameters:

- Thickness:

The thickness of the front-maintenance LED display is usually closely related to its structural design, heat dissipation performance and installation convenience. A thinner display not only saves space, but also improves the overall aesthetics.

However, a too thin display may face challenges in heat dissipation and mechanical strength. Therefore, when choosing, the balance between thickness and performance should be found according to the specific application scenario and needs.

- Weight:

Weight is another important technical parameter, especially in scenarios where it needs to be installed on the ceiling, wall, or hanging structure. Lighter displays not only reduce the burden of installation and maintenance but also reduce the requirements for the installation structure.

When selecting, the total weight of the display and the weight of a single module should be considered to ensure that it meets the load-bearing capacity of the installation environment.

- Structural design:

The structural design of the front-maintenance LED display is crucial to its maintenance convenience, reliability, and durability.

Excellent structural design should facilitate quick access to the back of the display for maintenance operations while ensuring that the connection between modules is firm and reliable.

In addition, the structural design should also consider heat dissipation performance to ensure the stability and life of the display when running under high load.

2). Selection recommendations

When choosing a front-maintenance LED display, the appropriate screen type should be selected according to the specific application scenarios and needs. Here are some suggestions:

- Indoor/outdoor LED selection:

Indoor LED displays usually have higher resolution, richer colors, and more sophisticated display effects and are suitable for occasions where high-quality images and videos need to be displayed.

Outdoor LED displays, on the other hand, pay more attention to brightness, waterproof and dustproof performance, and weather resistance to ensure normal display in harsh environments.

Therefore, when choosing, it should be determined whether to choose an indoor or outdoor display based on the installation environment and purpose of the display.

- High resolution/normal resolution:

High-resolution display screens can present more delicate and clear images and are suitable for occasions where images and videos with rich details and rich colors need to be displayed.

On the other hand, normal-resolution display screens focus more on cost-effectiveness and practicality and are suitable for occasions where image quality is not required.

When choosing, the relationship between resolution and price should be weighed according to the specific application scenario and budget.

- Other factors:

In addition to the above factors, performance indicators such as brightness, contrast, refresh rate, viewing angle, and the supplier’s after-sales service and technical support capabilities should also be considered. These factors will directly affect the use effect and user experience of the display screen.

4. Precautions for installation and post-maintenance of front-maintenance LED display screens

1). Site survey:

Before installing the front-maintenance LED display screen, a detailed survey of the installation site must be carried out.

This includes measuring the size of the installation space, determining the installation location, checking whether the load-bearing structure meets the requirements, and evaluating the temperature, humidity, and lighting conditions of the surrounding environment.

Ensure that the infrastructure, such as the on-site power supply and signal lines, meet the operating requirements of the display screen and reserve sufficient maintenance space.

2). Structural design evaluation:

Based on the results of the on-site survey, the structural design of the display screen is evaluated. Ensure that the design of the display screen’s fixing method, cooling system, maintenance channel, etc. meets the actual installation requirements.

Pay special attention to safety factors in the structural design, such as anti-falling and anti-dumping measures.

3). Professionalism of the installation team:

Choose an installation team with rich experience and expertise to install the display screen. Ensure that team members are familiar with the installation process, operating specifications, and safety requirements of the display screen.

Before installation, provide necessary training and guidance to the installation team to ensure that they can complete the task correctly and efficiently.

Quality control during installation

4). Ensure installation accuracy:

During the installation process, the installation accuracy is strictly controlled. Ensure that the connection between the various modules and components of the display screen is firm and reliable and the position is accurate.

Use professional measuring tools and methods to accurately measure and adjust the installation position, tilt angle, etc., of the display screen.

5). Safety inspection:

During the installation process, always put safety first. Take necessary safety protection measures at the installation site, such as setting safety warning signs and wearing safety equipment.

Carry out strict safety inspections on the electrical connection and grounding of the display screen to ensure that there are no safety hazards when the display screen is in operation.

Conclusion

In summary, the pre-installation maintenance LED display screen has shown high applicability and competitiveness in multiple application scenarios with its unique advantages.

Whether in a busy urban area with limited space or in a high-altitude installation environment with extremely high safety requirements, the pre-maintenance design can provide a more convenient and efficient maintenance solution.

Finally, if you want to know more about LED display screens, please get in touch with us.