Introduction

In today’s world, where digitalization and visualization are highly integrated, LED display screens, as an important carrier of information transmission and visual display, are undergoing technological innovations with each passing day.

With the continuous improvement of market requirements for display effects, LED curved screens have gradually become the darling of commercial displays, performing arts activities, sports events, and other fields with their unique morphological advantages and immersive visual experience.

However, traditional multi-screen splicing technology is often accompanied by obvious gaps, which not only affects the integrity of the picture but also reduces the audience’s visual enjoyment. Therefore, the seamless splicing technology of LED curved screens came into being. It aims to eliminate the physical and visual boundaries between screens through technological innovation and achieve a smoother and more coherent display effect.

1. Overview of seamless splicing technology of LED curved screens

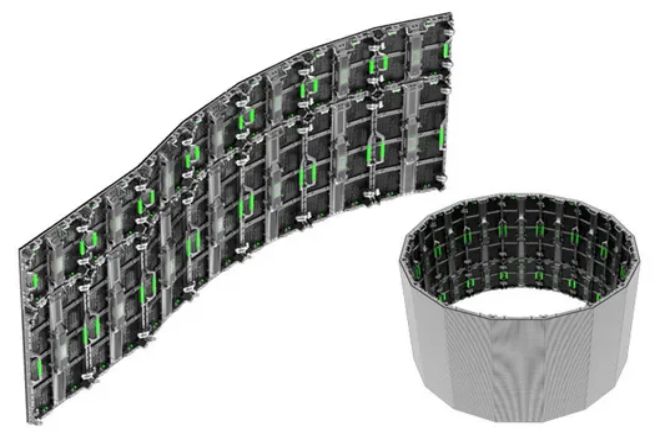

The seamless splicing technology of LED curved screens refers to the use of advanced splicing technology to combine multiple LED display units with extremely small gaps or almost no gaps to form a continuous and smooth curved display screen.

This technology requires not only a close physical fit but also a high degree of coordination and unity in image processing, color correction, brightness adjustment, etc., to achieve a seamless visual effect.

Its significance lies in that it can significantly improve the coherence and immersion of the display effect, reduce the visual fragmentation caused by the gap between the screens, and bring a smoother and more natural visual experience to the audience.

1). Technical background

The development of LED display technology has undergone a continuous evolution from monochrome to color, from flat to curved, and from small to large. With the continuous advancement of technology, the performance indicators of LED display screens, such as resolution, brightness, and color reproduction, have been significantly improved.

At the same time, in order to meet the market demand for larger sizes, wider viewing angles, and higher definition displays, curved screens and multi-screen splicing technology came into being.

Curved screens can simulate the natural field of the human eye and provide a more immersive viewing experience, while multi-screen splicing technology can achieve larger display screens to meet the display needs of large venues. On the basis of these two, LED curved screen seamless splicing technology has further promoted the innovation and development of LED display technology.

2). Application scenarios

LED curved screen seamless splicing technology has been widely used in many fields due to its unique advantages:

- Commercial display:

In shopping malls, exhibition halls, museums, and other places, LED curved screen seamless splicing technology can create a shocking visual effect, attract customers’ attention, and enhance brand image. Playing high-definition videos, dynamic advertisements, and other content provides merchants with a variety of display methods.

- Conference performance:

In large-scale conferences, concerts, sports events, and other activities, LED curved screen seamless splicing technology can build a grand stage background or auditorium display screen, bringing an immersive viewing experience to the audience.

At the same time, its high definition and high color reproduction also ensure the excellent performance of picture quality.

- Monitoring center:

In the monitoring center of transportation, security, energy, and other fields, LED curved screen seamless splicing technology can realize multi-screen, high-resolution real-time monitoring, help staff to fully grasp the on-site situation, and improve emergency response speed and decision-making efficiency.

2. Implementation method of seamless splicing technology

1). Software processing technology

1.1). Principle Introduction:

Software seamless splicing technology mainly relies on advanced image processing algorithms and technologies and accurately controls and processes the output signals of multiple LED display screens through software.

Specifically, the technology first identifies the physical gaps between each LED screen and uses image processing algorithms to perform complex calculations and compensation for these gaps.

By adjusting the brightness, color, and position of the pixels at the edges of adjacent screens, these gaps become visually imperceptible, thereby achieving a seamless splicing effect.

In addition, software processing technology can also optimize the overall picture, such as color correction, brightness balance, etc., to ensure that the display effect of the entire spliced screen is consistent.

1.2). Advantages:

High flexibility: Software processing technology can be flexibly configured dynamic range images and certain splicing traces may appear.

Certain requirements for hardware: Although the cost is relatively low, in order to achieve a good splicing effect, certain hardware support is still required, such as a high-performance image processor and a stable network transmission environment.

2). Hardware seamless splicing technology

2.1). Principle Introduction:

Hardware seamless splicing technology realizes multi-screen splicing by introducing additional hardware devices. These hardware devices may include dedicated control chips, topological structures, connectors, etc. In the hardware seamless splicing system, each LED display is connected to the control chip through a specific connection method to form an overall display system.

The control chip is responsible for receiving and processing video signals from the outside and then distributing the processed signals to each display for display.

At the same time, hardware seamless splicing technology also uses specific topological structures and connectors to ensure signal transmission and synchronous display between each display, thereby achieving a seamless splicing effect.

2.2). Advantages:

Better splicing effect: Due to the use of dedicated hardware devices and strict synchronization control mechanisms, hardware seamless splicing technology can achieve higher quality splicing effects, and reduce splicing marks and visual fragmentation.

Applicable to high-demand scenarios: For display scenarios that require high clarity, high color reproduction, and high stability, hardware seamless splicing technology has more advantages.

2.3). Limitations:

High cost: Compared with software processing technology, the initial investment cost of hardware seamless splicing technology is higher, including the cost of purchasing, installing, and maintaining hardware equipment.

Relatively low flexibility: The configuration and adjustment of hardware seamless splicing technology is relatively complex, and it is difficult to make large-scale changes or upgrades once the installation is completed.

3. Analysis of key technologies

1). Side routing technology

- Principle and implementation:

Side routing technology is an innovative LED display screen border design technology. It greatly reduces the width of the border by routing circuits on the side of the display screen instead of the traditional front and back panels.

The implementation of this technology relies on high-precision routing technology and advanced packaging technology. During the manufacturing process, the precision circuits are precisely arranged on the side of the LED module, and special packaging materials and technologies are used to protect these circuits from the external environment.

In this way, the side routing technology not only reduces the visual interference of the border but also enables multiple LED screens to achieve a closer fit when splicing, approaching a seamless splicing effect.

- Challenges and breakthroughs:

Although the side routing technology brings significant advantages, it also faces many challenges in practical applications. Anti-collision is the primary problem because the side wiring is relatively fragile and easily damaged by external forces.

In order to overcome this problem, the project team adopted strategies such as strengthening the frame structure and using highly wear-resistant materials to improve the durability of the display. In addition, waterproof oxygen is also an important challenge because moisture and oxygen may invade the interior of the display through tiny gaps, affecting the stability and life of the circuit.

The project team effectively solved this problem by optimizing the packaging process and adopting innovative technologies such as waterproof and breathable membranes.

2). Light modulation technology

- Principle and application:

Light modulation technology adjusts the light emitted by Micro-LED by preparing an optical modulation layer. In the LED curved screen seamless splicing system, the direction, intensity, and color characteristics of the light emitted by each Micro-LED can be precisely controlled after passing through the optical modulation layer.

This technology ensures that the light emitted by different LED modules can maintain a high degree of consistency at the splicing point, thereby solving the split screen problem and color difference. Through the application of light modulation technology, the entire spliced screen presents a more coherent and smooth effect visually.

- Effects and advantages:

The introduction of light modulation technology significantly improves the display effect of seamless splicing of LED curved screens. It can not only reduce the brightness difference under a wide viewing angle so that the audience can get a uniform visual experience at different positions.

It can also solve the color inconsistency problem caused by splicing, ensuring the best color reproduction of the entire screen. In addition, light modulation technology also helps to improve the contrast and clarity of the picture, further improving the overall display effect.

3). Pixel correction and color adjustment

- Methods and processes:

Pixel correction and color adjustment are important steps to ensure the best seamless splicing effect of LED curved screens. After the splicing is completed, professional equipment and software are required to conduct a comprehensive inspection and calibration of the screen.

First, the pixel correction algorithm is used to align the pixels of the spliced screen to ensure that the pixels of each module can be accurately matched. Then, the color of the screen is corrected and optimized using the color adjustment algorithm to reduce color difference and brightness differences.

This process requires repeated iterations and adjustments until the expected display effect is achieved.

- Quality control:

In order to ensure the best seamless splicing effect, the project team needs to implement strict product quality control and comprehensive inspection processes.

This includes strict quality inspection of each LED module, comprehensive performance testing of the spliced screen, and regular maintenance and upkeep of the system.

Through the implementation of these measures, the stability and reliability of the LED curved screen seamless splicing system can be effectively guaranteed, providing users with long-term, stable, and high-quality display effects.

4. Installation and debugging

1). Preparation

- Tool material preparation:

Before installing the LED curved splicing screen, you first need to prepare all the necessary tools and materials.

This includes but is not limited to special mounting brackets, fixing screws, power cords, signal cables, multimeters, electric drills, screwdrivers, etc. Make sure all tools are in good condition and check whether the materials are complete and meet the specifications.

- Space measurement:

Carefully measure the installation area to ensure that the space size can meet the installation requirements of the LED curved splicing screen. At the same time, pay attention to the load-bearing capacity of the wall or bracket at the installation location to ensure that it can safely support the weight of the entire screen.

During the measurement process, the needs of heat dissipation, ventilation, and later maintenance must also be considered.

- Bracket installation:

According to the measurement results and design plan, install a dedicated LED curved splicing screen bracket. The installation position, angle, and height of the bracket need to be precisely adjusted to ensure that the screen can be installed smoothly and firmly in the designated position. During the installation process, pay attention to the stability and balance of the bracket to avoid shaking or tilting.

2). Installation steps

- Module installation:

Install each module of the LED curved splicing screen on the bracket one by one in the designed order and position. During the installation process, pay special attention to the gap and alignment between the modules to ensure seamless splicing and good display effects. At the same time, use special fixing screws to firmly fix the module on the bracket.

- Power and signal line connection:

Connect the power cord and signal line of each module to the corresponding interface. During the connection process, make sure that the plugs of the power cord and signal line match the interface, and check whether the connection is firm and reliable.

At the same time, pay attention to the direction and layout of the cable to avoid excessive stretching or bending that may cause cable damage.

- Adjustment and testing:

After the installation is completed, adjust and test the LED curved splicing screen. First, adjust the screen’s brightness, contrast, color, and other parameters to ensure that the display effect meets the expected requirements.

Then, a content test will be performed to check whether the screen can display images and videos normally and ensure that the content is uniform and clear across the entire screen. During the test, pay attention to observing whether the screen has abnormal conditions such as flickering, black screen, or color distortion, and deal with them in time.

3). Precautions

- Safety first:

During the installation process, always put safety first. Make sure to use appropriate tools and equipment for operation and comply with relevant safety regulations and operating procedures. When dangerous operations such as climbing or contacting power are required, pay special attention to personal protection measures and seek help from professionals.

- Protect the screen surface:

During the installation process, pay special attention to protecting the screen surface of the LED curved splicing screen from scratches or damage. Avoid using sharp objects to touch the screen surface, and try to keep a clean and dust-free environment.

- Prevent damage:

During the installation process, pay attention to avoid collisions or impacts on the screen to avoid damage. At the same time, when carrying and installing the module, be gentle to avoid severe vibration or falling.

- Follow the manufacturer’s guide:

During the installation process, carefully read and follow the installation guide and operating manual provided by the manufacturer. Installing according to the correct steps and methods can ensure the quality and effect of the installation and reduce unnecessary troubles and losses.

- Regular inspection and maintenance:

After the installation is completed, the LED curved splicing screen should be regularly inspected and maintained to ensure its normal operation and long-term stable use. This includes cleaning the screen surface, checking whether the cable connection is firm, and making necessary repairs and replacements.

Conclusion

In summary, as an important milestone in modern display technology, LED curved screen seamless splicing technology not only greatly improves the continuity and viewing of the picture but also brings unprecedented visual experience to all walks of life.

With the continuous maturity of technology and the continuous expansion of applications, we have reason to believe that seamless splicing technology will play a more important role in the future and become an important driving force for the development of the LED display industry.

Finally, if you want to know more about LED display screens, please get in touch with us.