Introduction

Avec le développement rapide de la science et de la technologie, Afficheurs LED have been widely used in various scenarios, such as commercial advertising, sports events, public information releases, etc., and have become an indispensable part of modern society.

LED display screens have won wide recognition in the market with their advantages, such as high brightness, high definition, and low energy consumption. However, as the use time increases, the maintenance problems of LED displays have become increasingly prominent. Correct maintenance measures can not only extend the service life of the display but also ensure its stable operation and provide viewers with a high-quality visual experience.

This article will focus on the wrong practices in LED display maintenance, aiming to remind users and managers to avoid these misunderstandings and ensure the long-term stable operation of LED displays.

1. Neglect regular cleaning

As a high-precision and high-sensitivity display device, LED display screens are prone to accumulation of dust and dirt on their surfaces. This dust and dirt will not only affect the visual effect of the display and reduce the viewing experience of the audience but may also cause damage to the performance and life of the display.

1). Problems that are ignoring regular cleaning can cause

When dust and dirt accumulate on the surface of the display screen, they will block the light emitted by the LED lamp beads, resulting in reduced display effects and problems such as blurring and color distortion.

In addition, dust will also affect the heat dissipation performance of the display, causing the temperature of the LED lamp beads to be too high, thereby shortening its service life. In extreme cases, excessive temperatures may cause fires and other safety incidents.

2). The importance of regular cleaning

In order to maintain the good performance of the LED display and extend its service life, regular cleaning is essential. The cleaning cycle should be determined according to the actual use environment and conditions. It is generally recommended that deep cleaning be conducted every quarter or every six months.

During the cleaning process, the correct cleaning methods and tools should be selected. Generally speaking, you can use a soft, dry cloth or a special cleaning cloth to gently wipe the display surface to remove dust and dirt.

For stubborn stains, special cleaners can be used for cleaning, but care should be taken to avoid using chemical cleaners or strong acid and alkali solutions to avoid damage to the display.

At the same time, you also need to pay attention to the following things during the cleaning process:

Make sure the display is off and disconnect from the power source to prevent electric shock.

Avoid using sharp tools or hard objects to scratch the display surface to avoid scratching or damaging the LED lamp beads.

Pay attention to keeping the surface of the display screen dry to avoid moisture entering the interior of the display screen and causing short circuits or damage.

3). Examples of wrong practices

Some people may use some wrong methods when cleaning LED displays, such as chemical cleaners or high-pressure water guns to directly rinse the display.

These practices are undesirable because chemical cleaners may corrode the coating or lamp beads on the display surface, while high-pressure water guns may splash moisture into the interior of the display, causing short circuits or damage.

Not only will these incorrect practices fail to effectively clean your display, but they may also cause serious damage to it. Therefore, when cleaning the LED display, be sure to follow the correct cleaning methods and precautions to ensure the safe and stable operation of the display.

2. Irregular power management

In the maintenance of LED display screens, power management is a crucial link. Irregular power management may cause a series of problems, which not only affect the normal operation of the display but may also shorten its service life.

1). Possible problems caused by non-standard power management

First of all, voltage instability is one of the common causes of display damage. When the voltage fluctuation is too large, the electronic components of the LED display may not be able to withstand the impact, resulting in damage. In addition, frequent voltage fluctuations may also affect the display effect of the display, causing problems such as flickering and color distortion.

Secondly, frequent and irregular switching on and off will also have a negative impact on the life of the LED display. Every time you turn on the computer, the display needs to go through a process from cold to hot, which will produce a certain amount of thermal stress.

If the machine is turned on and off frequently, thermal stress will continue to accumulate, which may eventually lead to damage to the LED lamp beads or other electronic components.

2). The importance of regulating power management

In order to ensure the stable operation of the LED display and extend its service life, standardized power management measures must be taken. This includes the following aspects:

Use a stable and reliable power source. Choose power adapters and cables of good quality and high stability to ensure a stable and pure power supply for the display. Avoid using low-quality power adapters to avoid damage to the display.

Set reasonable power on and off times. According to the actual needs and usage conditions, reasonably set the power on and off time of the display screen. Avoid frequent and irregular power on and off to reduce thermal stress damage to the display.

Check power lines regularly. Regularly inspect and maintain power lines to ensure their safety and reliability. When problems such as aging or damage to the circuit are found, they should be replaced or repaired in time.

3). Examples of wrong practices

In actual applications, some people may take some irregular power management measures, causing problems with the display. Here are some examples of common bad practices:

Use a poor-quality power adapter. In order to save costs, some users choose to use cheap but unreliable power adapters. This power adapter may not be able to provide a stable, pure power supply to the display, causing various problems with the display.

Power on and off frequently and erratically. Some users may frequently switch the LED display on and off for convenience or to save energy. This approach will cause unnecessary thermal stress damage to the display and shorten its service life. The correct approach is to set the power on and off time reasonably based on actual needs and usage.

3. Ignore the impact of environmental factors

As an electronic device, the performance and service life of LED display screens are greatly affected by environmental factors. During the maintenance process, we must fully consider and respond to these environmental factors to ensure the normal operation of the display and extend its service life.

1). The impact of environmental factors on LED display screens

- Température:

Temperature is one of the key factors affecting the performance of LED displays. Temperatures that are too high or too low may cause damage to the electronic components of the display, leading to performance degradation or failure.

Excessively high temperatures may reduce the luminous efficiency of the display screen, cause light attenuation, and may accelerate its aging process. Too low a temperature may cause the display to be difficult to start or not work properly.

- Humidité:

The impact of humidity on LED displays cannot be underestimated. A high-humidity environment may cause the electronic components inside the display to become damp, causing problems such as corrosion, leakage, and short circuits.

In addition, excessive humidity may also affect the heat dissipation performance of the display, causing the temperature to rise and further aggravating its aging process.

- Lighting:

Lighting conditions also have a certain impact on the display effect and life of the LED display. Strong light may cause the brightness and contrast of the display to decrease, thus affecting the audience’s viewing experience. In addition, prolonged exposure to strong light may accelerate the aging process of the display.

2). Environmental factors need to be considered during maintenance

In order to ensure the normal operation of the LED display and extend its service life, we must fully consider environmental factors during the maintenance process and take corresponding measures to ensure the stability and reliability of the display.

- Contrôle de la température:

Ensure that the display screen works within a suitable temperature range by installing temperature control equipment or taking other measures. In high-temperature environments, cooling measures can be taken, such as adding cooling fans, installing sun visors, etc.; in low-temperature environments, heating equipment can be used to increase the operating temperature of the display.

- Humidity control:

Keep the humidity of the environment around the display screen within a suitable range to avoid damage to the display screen due to excessively high or low humidity.

Humidity can be reduced by installing dehumidification equipment or taking other measures; in environments with high humidity, waterproof and moisture-proof materials can also be used to protect the display.

- Light protection:

In strong light environments, you can reduce the impact of light on the display by installing sun visors, using light-blocking materials, or adjusting the brightness and contrast of the display. In addition, you can also choose an LED display with anti-light interference capabilities to adapt to different lighting conditions.

3). Examples of wrong practices

During the actual maintenance process, some people may ignore the influence of environmental factors and adopt some wrong practices, such as:

Failure to take protective measures under extreme weather conditions: Under extreme weather conditions such as exposure to the sun and rain, if necessary protective measures are not taken for the display, the display may be damaged or its performance degraded.

The correct approach is to turn off the display in extreme weather conditions and take measures such as waterproofing and sun protection to protect the display.

Ignoring changes in temperature and humidity: Some people may think that temperature and humidity have little impact on the display, so they ignore changes in temperature and humidity. However, this neglect can cause the display to malfunction or degrade in performance over the long term.

The correct approach is to regularly monitor the temperature and humidity around the display and take appropriate measures to adjust as necessary.

4. Wrong repair and replacement methods

The maintenance and replacement of LED displays require professional knowledge and skills. Wrong operations may not only fail to solve the problem but may also bring about a series of negative impacts. Therefore, it is important to know and follow the correct repair and replacement methods.

1). Possible consequences of incorrect repair and replacement methods

- Damage to other components:

When non-professionals disassemble the display without authorization, due to a lack of necessary professional knowledge and skills, they may misoperate or use improper force, causing damage or damage to other components inside the display. Not only does this increase repair costs, but it may also affect the overall performance of the display.

- affects the overall performance of the display:

When using mismatched parts for replacement, the overall performance of the display may be degraded due to compatibility issues between the parts. For example, using an inappropriate power adapter may cause voltage instability, affecting the stability and lifespan of the display.

2). The importance of correct repair and replacement methods

In order to avoid the above problems, correct maintenance and replacement methods must be adopted. This includes the following aspects:

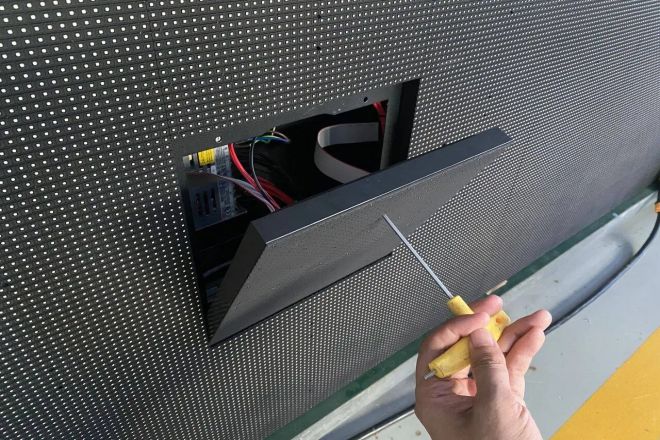

Use professional tools: During repair and replacement, professional tools and equipment should be used to ensure the accuracy and safety of the operation. Non-professional tools may cause operating errors or damaged components.

Follow the operating procedures: When performing repairs and replacements, the corresponding operating procedures and procedures must be followed. This includes turning off the power first, disassembly sequence, installation sequence, etc. Following procedures ensures correct and safe operations.

Use matching parts: When replacing parts, you must choose parts that match the original parts. This ensures compatibility between parts and the overall performance of the display.

3). Examples of wrong practices

Here are two examples of common incorrect repair and replacement methods:

Unauthorized disassembly of the display by non-professionals: Some users or non-professionals may try to disassemble the display for repairs. However, due to a lack of professional knowledge and skills, they may mishandle or damage the components inside the display.

The correct approach is to send the display screen to a professional maintenance agency for repair.

Use mismatched parts for replacement: Some users may choose to use mismatched parts when replacing parts of the display. This may cause the display to degrade or malfunction. The correct approach is to choose replacement parts that match the original parts and ensure that their quality and performance meet the requirements.

5. Lack of maintenance and inspection records

Maintenance and inspection records play a vital role in the long-term use of LED displays. However, some users or administrators may overlook this, leading to a series of potential problems.

1). Possible problems caused by lack of maintenance and inspection records

Unable to detect potential problems in time: Without maintenance and inspection records, we cannot have a complete understanding of the historical operating status of the display.

This may cause some potential problems to be ignored until the problem actually occurs, thereby increasing repair costs and affecting the normal use of the display.

It is difficult to trace the cause of the problem: When the display fails, without maintenance and inspection records as a reference, it will be difficult to trace the specific cause of the problem. This not only increases the difficulty of troubleshooting but may also lead to recurring problems that cannot be fundamentally solved.

2). The Importance of Establishing Maintenance and Inspection Records

Establishing maintenance and inspection records is of great significance to ensure the stable operation of LED displays. Specifically, it helps us:

- Timely discovery of potential problems:

Through regular maintenance and inspection and recording relevant information, we can discover potential problems with the display in a timely manner, such as the aging of a certain component, performance degradation, etc. This allows steps to be taken in advance to avoid further problems.

- Tracing the cause of the problem:

When the display fails, we can understand the historical operating status and related operations of the display by consulting the maintenance and inspection records. This helps us quickly locate the cause of the problem and take appropriate solutions.

- Optimize maintenance strategies:

By analyzing maintenance and inspection records, we can understand the usage and performance changes of the display. This helps us optimize maintenance strategies and improve maintenance efficiency and quality.

3). Examples of wrong practices

Some users or managers may only perform maintenance and replacement based on experience without any maintenance and inspection records. This approach may cause the following problems:

Unable to accurately assess the display’s status: Without records to use as a reference, we cannot accurately assess the display’s current status and performance. This may cause us to miss some important maintenance opportunities or take inappropriate maintenance measures.

Unable to trace historical problems: When the display fails, since there is no record as a reference, it will be difficult for us to trace historical problems. This may result in us not being able to find the root cause of the problem and therefore not being able to fundamentally solve the problem.

Therefore, in order to ensure the stable operation of the LED display and extend its service life, we must pay attention to the importance of maintenance and inspection records and establish a complete recording system.

Conclusion

Through the discussion in this article, it is not difficult to find that the maintenance of LED display screens is not a simple task that can be accomplished overnight, but requires care, patience and professional technical support.

Wrong maintenance practices may not only cause damage to the display, but may also affect the operation of the entire system. Therefore, we call on users and managers to follow correct operating procedures and maintenance methods during the maintenance process of LED displays to avoid misunderstandings.

Enfin, si vous souhaitez en savoir plus sur les écrans LED, veuillez nous contacter.