Introduction

Écrans LED sont largement utilisés sur le organiser. Vous pouvez maintenant voir que presque toutes les scènes légèrement plus grandes ont des écrans LED.

Cependant, lorsque vous achetez des écrans LED pour une utilisation sur scène, le personnel vous recommandera d'acheter des écrans dotés de performances de protection élevées. Pourquoi en est-il ainsi ? Cet article analysera ce problème. Jetons un œil.

1. Analyse de la particularité de l'environnement scénique

En tant que système complexe qui intègre l'expression artistique et le support technique, la particularité de l'environnement scénique a un impact profond sur le choix de l'équipement scénique, la présentation des effets de performance et l'expérience des acteurs et du public :

1). Conditions climatiques variables

1.1). L'impact des différences de température et d'humidité intérieures et extérieures sur les équipements électroniques :

L'environnement scénique doit souvent être converti entre différents lieux intérieurs et extérieurs.

Les variations de température et d'humidité représentent un défi majeur pour les équipements électroniques. Des différences de température excessives peuvent provoquer des contraintes sur les composants internes des équipements électroniques en raison de la dilatation et de la contraction thermiques, ce qui affecte à son tour leur structure physique et la stabilité de leurs performances électriques.

Une humidité excessive peut provoquer de l'humidité à l'intérieur de l'équipement électronique, entraînant des courts-circuits, la corrosion des composants et d'autres problèmes, tandis qu'une humidité trop faible peut provoquer une décharge électrostatique et endommager les composants sensibles de l'équipement électronique.

Par conséquent, l'équipement de scène doit avoir une bonne adaptabilité à la température et à l'humidité ou prendre des mesures supplémentaires de contrôle de la température et de l'humidité, telles que l'installation d'équipements de réglage de la température et de l'humidité, l'utilisation de matériaux résistants à l'humidité, etc., pour assurer le fonctionnement normal de l'équipement.

1.2). Exigences en matière d'imperméabilité et de résistance à l'humidité en cas de mauvais temps, comme les jours de pluie et de brouillard :

Lors des représentations en extérieur, les intempéries, comme les jours de pluie et de brouillard, constituent des défis courants. L'eau de pluie peut pénétrer directement dans les équipements scéniques, entraînant de graves conséquences telles que des courts-circuits et des dommages aux composants.

Les jours de brouillard peuvent augmenter l'humidité des équipements de scène et accélérer le processus de corrosion et de vieillissement des équipements. Par conséquent, en cas de mauvais temps, des mesures strictes d'étanchéité et de résistance à l'humidité doivent être prises.

Par exemple, des matériaux de protection tels que des housses et des tissus imperméables doivent être utilisés pour envelopper l'équipement afin de garantir qu'il reste sec et stable en cas de mauvais temps.

2). Chocs physiques et vibrations

2.1). Collision accidentelle lors du montage et du démontage de la scène :

Le processus de construction et de démontage d’une scène est un processus complexe et fastidieux impliquant la collaboration d’un grand nombre d’équipements et de personnel.

Au cours de ce processus, l'équipement peut entrer en collision en raison d'un fonctionnement incorrect ou de circonstances inattendues, entraînant des dommages ou une dégradation des performances.

Par conséquent, pendant le processus d'installation et de démontage, les procédures d'exploitation doivent être strictement suivies et l'équipement doit être manipulé avec soin pour éviter toute collision inutile et tout dommage à l'équipement.

2.2). Contact possible entre les accessoires ou le personnel pendant la représentation :

Lors d'une représentation sur scène, les accessoires et les acteurs sont des éléments indispensables. Cependant, le mouvement des accessoires et le jeu des acteurs peuvent entrer en contact avec des équipements scéniques, tels que le son et l'éclairage.

Un tel contact peut endommager l'équipement, dégrader les performances ou affecter l'effet de la performance. Par conséquent, lors de l'aménagement de la scène et de l'installation de l'équipement, la gamme d'activités des accessoires et des acteurs doit être pleinement prise en compte pour garantir qu'il existe une distance de sécurité suffisante entre l'équipement et les accessoires et les acteurs afin d'éviter tout contact et collision inutiles.

3). Poussière et pollution

3.1). Pollution particulaire générée par les effets spéciaux de scène (tels que la fumée et la mousse) :

Les effets spéciaux scéniques sont un moyen important d’améliorer l’effet de la performance et l’expérience du public.

Cependant, les effets spéciaux tels que la fumée et la mousse peuvent générer un grand nombre de particules qui peuvent adhérer à l'équipement de scène et affecter sa finition de surface et ses performances. Une accumulation à long terme peut également entraîner des problèmes tels qu'un blocage interne et une mauvaise dissipation de la chaleur de l'équipement.

Par conséquent, l'équipement de scène doit être nettoyé et entretenu régulièrement pour garantir que sa surface est propre et sans poussière, et que l'intérieur est dégagé et débloqué.

3.2). Poussière soulevée dans la zone du public :

L'espace public est un élément indispensable des performances scéniques. Cependant, les activités du public peuvent soulever beaucoup de poussière, qui peut également pénétrer dans l'équipement scénique et l'endommager.

Le problème de la poussière est particulièrement important lors des représentations en extérieur ou lors d'événements avec un public nombreux. Il est donc nécessaire de maintenir la zone d'accueil du public propre et bien rangée pour réduire la production et la levée de poussière.

Dans le même temps, des filets anti-poussière, des housses anti-poussière et d'autres mesures de protection peuvent être installés autour de l'équipement de scène pour réduire davantage l'impact de la poussière sur l'équipement.

2. Quelle est la définition et la norme de performance de haute protection des écrans d'affichage LED ?

1). Introduction à l'indice IP

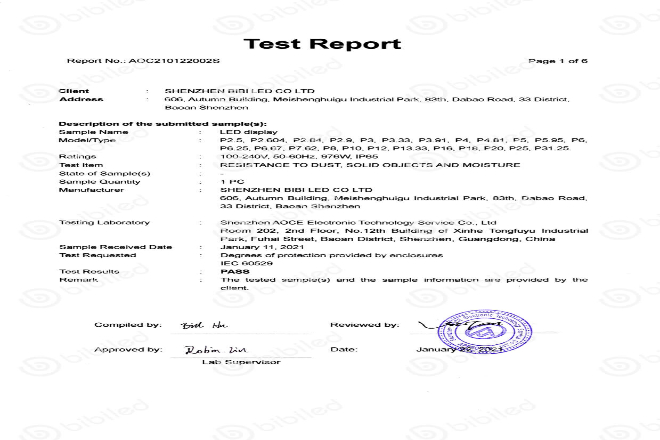

L'indice de protection IP (Ingress Protection), en tant que norme de protection des équipements électroniques acceptée à l'échelle internationale, vise à évaluer et à définir de manière exhaustive la capacité de protection du boîtier de l'équipement contre les particules solides et les liquides externes.

Cette norme est soigneusement formulée par la Commission électrotechnique internationale (CEI) et garantit le fonctionnement stable des équipements électroniques dans différentes conditions environnementales grâce à une série de procédures de test rigoureuses.

1.1). Explication détaillée des normes anti-poussière :

- IP6X:

Cette classification représente la performance ultime en matière d'étanchéité à la poussière. Plus précisément, cela signifie que la structure interne de l'écran LED peut complètement résister à l'intrusion de poussière et que, quelle que soit la taille ou la forme des particules de poussière, elles ne peuvent pas pénétrer la coque et pénétrer à l'intérieur de l'appareil.

Cette norme est d’une importance vitale pour les endroits qui nécessitent un environnement très propre, tels que les établissements médicaux, les ateliers de fabrication de précision, etc.

1.2). Explication détaillée des normes d'étanchéité :

- IPX7:

Cette note souligne les excellentes performances d'étanchéité de l'appareil. Dans des conditions de test spécifiques, l'écran LED peut être immergé dans 1 mètre d'eau pendant 30 minutes sans aucun dommage.

Cette norme constitue une garantie essentielle pour assurer le fonctionnement stable des équipements dans des lieux tels que les spectacles en plein air, les stades, les piscines, etc., qui sont souvent exposés à la pluie ou aux éclaboussures d'eau.

Pour les écrans LED extérieurs, l'indice IP65 est un choix plus courant. Cet indice offre non seulement une protection complète contre la poussière (IP6X), mais résiste également efficacement aux projections d'eau de toutes les directions (IP5), garantissant que l'écran peut toujours conserver un effet d'affichage clair et stable dans des conditions météorologiques défavorables.

2). Autres certifications pertinentes

Outre l'indice IP, les écrans d'affichage LED doivent également répondre à une série de normes internationales strictes en matière de qualité des produits et de performances environnementales.

2.1). Certification CE :

Le marquage CE, en tant que marque de certification de sécurité obligatoire imposée par le marché européen sur les produits entrant sur son territoire, exige que les produits soient conformes à de nombreuses normes européennes en matière de santé, de sécurité et de protection de l'environnement.

Pour les écrans d'affichage LED, l'obtention de la certification CE signifie non seulement que ses performances en matière de sécurité électrique sont entièrement garanties, mais indique également qu'il a satisfait aux exigences strictes du marché européen en termes de compatibilité électromagnétique et de contrôle des rayonnements.

2.2). Certification RoHS :

La directive RoHS (Restriction of Hazardous Substances) est une exigence restrictive formulée par l'Union européenne concernant le contenu de substances dangereuses spécifiques dans les équipements électroniques et électriques.

La directive stipule clairement la teneur maximale autorisée en substances dangereuses telles que le plomb, le mercure et le cadmium dans les produits électroniques, visant à réduire les dommages potentiels de ces substances dangereuses pour la santé humaine et l'environnement.

Les écrans d'affichage LED qui ont obtenu la certification RoHS ont une sélection de matériaux plus respectueuse de l'environnement, minimisant l'impact sur la santé humaine et l'environnement.

2.3). Certification spéciale pour des scénarios d'application spécifiques :

Pour des scénarios d'application spécifiques tels que les performances en extérieur, les écrans d'affichage LED doivent également répondre à une série d'exigences de certification particulières.

Par exemple, compte tenu de l'impact des vibrations de la scène et de l'impact sur la stabilité de l'équipement, l'écran d'affichage à LED doit avoir de bonnes performances antisismiques ; en même temps, afin de garantir la stabilité de l'équipement dans le cadre d'un fonctionnement à haute luminosité à long terme, ses performances de dissipation thermique doivent également répondre à certaines normes.

De plus, pour les applications dans certains endroits spéciaux (tels que les usines chimiques, les champs pétrolifères, etc.), les écrans d'affichage LED doivent également avoir des propriétés spéciales telles que l'antidéflagrant et l'anticorrosion.

Ces exigences de certification spéciales sont basées sur des scénarios d'application spécifiques et visent à garantir que l'écran d'affichage LED peut maintenir d'excellentes performances de travail et prolonger sa durée de vie dans divers environnements difficiles.

(Si vous souhaitez en savoir plus sur les certificats d'affichage de BIBILED, veuillez cliquer ici)

3. Quel est l’impact spécifique des performances de protection élevées sur les écrans LED de scène ?

L’impact spécifique des performances de protection élevées sur les écrans LED de scène est vaste et complet.

Cela n'a pas seulement un impact sur la durée de vie et la stabilité de l'affichage lui-même, mais affecte également directement l'effet, la sécurité et la capacité des performances scéniques à s'adapter à diverses scènes. Voici un examen plus approfondi de ces impacts :

1). Prolonger la durée de vie

L'écran LED de scène hautement protecteur réduit considérablement le taux de défaillance causé par des facteurs environnementaux grâce à son excellente conception étanche, anti-poussière, résistante aux tremblements de terre et aux chocs, prolongeant ainsi considérablement la durée de vie de l'écran.

- Conception étanche à l'eau et à la poussière :

L'environnement de la scène est souvent complexe et changeant, et l'humidité, la poussière et d'autres polluants constituent une menace sérieuse pour l'affichage LED.

L'écran hautement protecteur adopte une coque hautement scellée et une technologie avancée d'étanchéité à l'eau et à la poussière, qui bloque efficacement l'intrusion de ces substances nocives, évite les pannes causées par la corrosion, les courts-circuits et d'autres problèmes, et assure le fonctionnement stable à long terme de l'écran.

- Résistance sismique et aux impacts :

Les collisions et vibrations accidentelles lors du montage, du démontage et des représentations sur scène peuvent endommager l'écran LED.

L'écran d'affichage haute protection présente une excellente résistance aux tremblements de terre et aux chocs et peut résister à ces forces externes, préservant ainsi l'intégrité de l'appareil et prolongeant encore sa durée de vie.

- Coûts de maintenance réduits :

Le taux de défaillance des écrans LED à haute protection étant extrêmement faible, le nombre de réparations ou de remplacements d'équipements est considérablement réduit, ce qui réduit les coûts de maintenance. Il s'agit sans aucun doute d'une économie considérable pour une scène où des performances doivent souvent être réalisées.

2). Améliorer l'effet d'affichage

L'affichage LED de scène avec des performances de protection élevées fonctionne également bien en termes d'effet d'affichage, apportant une expérience visuelle plus claire et plus stable au public.

- Étanche et anti-poussière, protège l'écran de la pollution :

Les écrans LED sur scène sont souvent affectés par des effets spéciaux tels que des lumières et de la fumée et sont facilement contaminés par la poussière et l'humidité.

L'écran d'affichage avec des performances de protection élevées peut efficacement empêcher l'intrusion de ces polluants, maintenir la propreté de la surface de l'écran et garantir que la clarté et la luminosité de la qualité de l'image ne sont pas affectées.

- Un bon système de dissipation thermique assure la luminosité et la stabilité des couleurs :

Les performances sur scène durent souvent longtemps et les écrans LED doivent conserver une luminosité élevée pendant longtemps.

L'écran d'affichage haute protection est équipé d'un système de dissipation thermique avancé, qui peut dissiper efficacement la chaleur générée lorsque l'équipement fonctionne, éviter les problèmes tels que la baisse de luminosité et la distorsion des couleurs causées par la surchauffe et assurer la stabilité de l'effet d'affichage.

3) Améliorer la sécurité

L'affichage LED de scène avec des performances de protection élevées présente également des avantages significatifs en matière de sécurité, offrant une solide garantie du bon déroulement de la performance.

- Prévenez les risques de sécurité tels que les courts-circuits électriques et les incendies :

Il y a beaucoup d’équipements électriques sur scène, et les risques de sécurité tels que les courts-circuits électriques et les incendies ne peuvent être ignorés.

L'écran hautement protecteur utilise des matériaux de haute qualité et des processus de fabrication avancés pour prévenir efficacement les problèmes de sécurité tels que les courts-circuits électriques et les incendies causés par l'humidité, la poussière et d'autres substances nocives.

- Réduisez le risque d’interruption des performances :

La performance sur scène nécessite une étroite coopération de tous les maillons, et la défaillance de l’un d’eux peut entraîner l’interruption de la performance.

Grâce à sa stabilité et sa fiabilité extrêmement élevées, l'affichage LED haute protection réduit considérablement le risque d'interruptions de performances dues à des pannes et garantit le bon déroulement des performances.

4) S'adapter à davantage de scénarios

L'écran d'affichage LED de scène hautement protecteur, avec son excellente adaptabilité et flexibilité, peut facilement faire face à diverses scènes de scène et besoins de conception complexes et changeants.

- Faire face à divers environnements difficiles :

Qu'il s'agisse d'un théâtre en salle ou d'un festival de musique en plein air, l'environnement scénique peut être confronté à des défis tels que des conditions météorologiques difficiles et des aménagements de lieux complexes.

L'écran d'affichage haute protection est parfaitement étanche, résistant à la poussière, aux tremblements de terre et aux chocs, et il peut facilement faire face aux environnements difficiles pour garantir des performances fluides.

- Prend en charge les exigences complexes et changeantes en matière de conception de scène et d'effets spéciaux :

Les performances scéniques recherchent souvent la présentation ultime des effets visuels, nécessitant des écrans LED hautement flexibles et personnalisables.

L'écran d'affichage haute protection prend en charge diverses conceptions de scène complexes et modifiables et des exigences d'effets spéciaux, telles que des écrans incurvés, des écrans de forme spéciale, des écrans transparents, etc., apportant une expérience visuelle plus choquante et unique au public.

En résumé, l’impact des performances de protection élevées sur les écrans LED de scène est multiforme et de grande portée.

Il prolonge non seulement la durée de vie de l'écran, améliore l'effet d'affichage et renforce la sécurité, mais permet également à l'écran de s'adapter aux besoins de davantage de scènes, offrant une présentation visuelle plus fiable, stable et excellente pour les performances sur scène.

Par conséquent, lors de la sélection d'un écran LED de scène, ses performances de protection doivent être pleinement prises en compte pour garantir le fonctionnement stable de l'équipement et le bon déroulement des performances.

4. Comment choisir un écran LED de scène avec des performances de protection élevées ?

La sélection d'un écran LED de scène avec des performances de protection élevées est un processus systématique et méticuleux qui nécessite une prise en compte minutieuse de plusieurs aspects pour garantir que l'écran sélectionné peut répondre aux besoins de performances spécifiques et maintenir un fonctionnement stable et fiable dans divers environnements. Voici une explication détaillée et officielle des étapes clés du processus de sélection :

1). Clarifier les besoins et déterminer le niveau de protection

Avant de choisir un écran LED de scène avec des performances de protection élevées, la première tâche consiste à clarifier le type de performance, les conditions du lieu et les éventuels facteurs environnementaux qui détermineront le niveau de protection requis.

- Analyse du type de performance :

Différents types de performances ont des exigences de protection différentes pour les écrans LED.

Par exemple, les festivals de musique en plein air peuvent être confrontés à des conditions météorologiques extrêmes telles que la pluie et les tempêtes de sable. Ils doivent donc choisir un écran doté de performances élevées en matière d'étanchéité à l'eau et à la poussière, tandis qu'un théâtre intérieur peut accorder plus d'attention à la luminosité, à la reproduction des couleurs et à la largeur de l'angle de vision de l'écran.

- Examen des conditions du lieu :

La taille, la forme, la disposition du lieu et le cadre de l’auditorium affecteront tous le choix de l’écran d’affichage.

Par exemple, les grandes salles extérieures peuvent avoir besoin de choisir des écrans avec une luminosité plus élevée et des angles de vision plus larges pour garantir que le public puisse voir clairement l'image à différents endroits, tandis que les théâtres intérieurs peuvent avoir besoin de prendre en compte la position d'installation et l'angle de l'écran pour éviter les reflets ou l'occlusion.

- Évaluation des facteurs environnementaux :

Les facteurs environnementaux susceptibles d’être rencontrés pendant la représentation, tels que la température, l’humidité, les vibrations, les interférences électromagnétiques, etc., doivent tous être pris en compte.

Choisir un écran capable de s’adapter à ces facteurs environnementaux peut garantir des performances fluides.

2). Examiner la force de la marque et se concentrer sur la réputation du marché

Lorsque vous choisissez une marque d’affichage LED, vous devez vous concentrer sur la force de sa marque, sa réputation sur le marché et sa certification professionnelle.

- Inspection de la force de la marque :

Choisir une marque forte, avec une longue histoire et une riche expérience peut garantir la qualité du produit et la fiabilité du service après-vente. Vous pouvez évaluer la force d'une marque en examinant les informations sur son histoire, son échelle de développement, son équipe de R&D, etc.

- Étude de réputation sur le marché :

Comprenez les performances et la réputation de la marque sur le marché en examinant les avis des utilisateurs, les rapports de l'industrie, les critiques des médias, etc. Choisir une marque avec une bonne réputation sur le marché peut réduire les risques de sélection et améliorer la satisfaction d'achat.

- Attention certification professionnelle :

Vérifiez si la marque a obtenu des certifications professionnelles dans des secteurs connexes, telles que la certification du système de gestion de la qualité ISO, la certification CE, la certification ROHS, etc. Ces certifications sont une preuve solide de la force de la marque et de la qualité du produit et constituent également une référence importante lors du choix d'une marque.

3). Comparez les paramètres techniques pour garantir des performances supérieures

Après avoir clarifié les besoins et inspecté les marques, il est nécessaire de comparer en détail les paramètres techniques des différents produits pour garantir que l'écran d'affichage sélectionné fonctionne à un niveau supérieur.

- Comparaison des niveaux IP :

Le niveau IP est un indicateur important pour mesurer la performance de protection de l'écran d'affichage. En fonction du type de performance et des conditions du lieu, choisissez un écran avec un niveau IP approprié.

Par exemple, pour les performances en extérieur, il est conseillé de choisir un écran avec un indice de protection IP65 ou supérieur afin de garantir qu'il puisse résister à la pluie, au sable et à d'autres conditions météorologiques extrêmes.

- Évaluation de la conception thermique :

Les performances thermiques affectent directement la luminosité et la durée de vie de l'écran. Le choix d'un écran doté d'une technologie de refroidissement avancée, telle que le refroidissement par liquide, le refroidissement par air ou le refroidissement par caloduc, peut garantir que l'écran reste stable lors d'un fonctionnement à haute luminosité à long terme et éviter une baisse de luminosité ou des dommages causés par une surchauffe.

- Considérations sur la durabilité des matériaux :

La qualité des matériaux d'un écran affecte directement sa durabilité et sa fiabilité. Le choix d'un écran composé de matériaux de haute qualité, tels que des perles de lampe LED résistantes aux intempéries, un boîtier anticorrosion, une surface d'écran résistante à l'usure, etc., peut garantir que l'écran conserve de bonnes performances et une bonne apparence pendant une utilisation à long terme.

4). Inspection et tests sur site pour vérifier la qualité du produit

Après avoir comparé les paramètres techniques, il est recommandé de procéder à une inspection sur site de la ligne de production du fabricant et de tester les performances de l'écran dans différents environnements sur site pour vérifier la qualité du produit.

- Visitez la ligne de production du fabricant :

En visitant la chaîne de production du fabricant, vous pourrez en apprendre davantage sur le processus de production, le processus de contrôle qualité et l'équipement de test. Le choix d'un fabricant doté d'équipements de production avancés et de systèmes de contrôle qualité stricts peut garantir la qualité et la stabilité du produit.

- Réalisation des tests sur site :

Tests sur site des performances de l'écran dans différents environnements, tels que la luminosité, la stabilité des couleurs, le contraste, la largeur de l'angle de vision, les performances d'étanchéité à l'eau et à la poussière, etc. Grâce à des tests réels, nous pouvons comprendre plus intuitivement les performances et la qualité de l'écran, offrant ainsi une base solide pour la sélection.

Conclusion

Pour résumer, l’affichage LED de scène avec des performances de protection élevées est l’un des facteurs clés pour assurer le succès de la performance et améliorer l’expérience du public.

Au cours du processus de sélection, nous devons prendre en compte de manière exhaustive plusieurs aspects tels que les besoins réels, les performances du produit, la réputation de la marque et le service après-vente pour garantir que l'écran LED sélectionné peut véritablement répondre aux exigences élevées des performances sur scène.

Enfin, si vous souhaitez en savoir plus sur les écrans LED, veuillez nous contacter.