Introduction

Large écrans LED extérieurs have become an indispensable part of the urban landscape with their excellent visual impact, high-definition display effects, and flexible playback content. They not only bear the important responsibilities of advertising and information dissemination but also are important windows for the display of urban images and cultural dissemination.

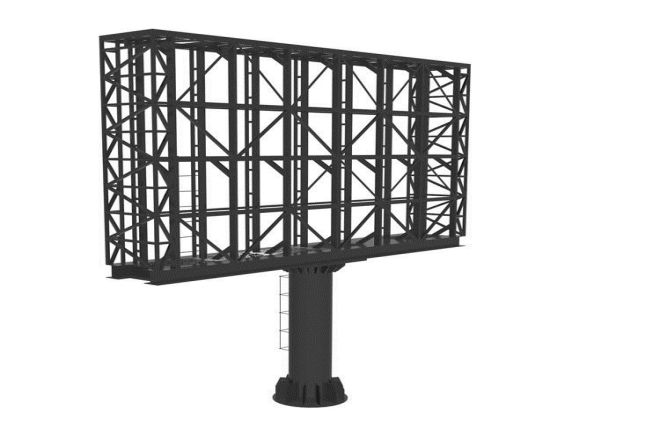

However, as the “skeleton” supporting these displays, the design and construction quality of the steel structure are directly related to the stability and safety of the display and are the key to ensuring that the display can operate long-term, stably, and safely.

With the continuous advancement of technology and the increasing expansion of the market, the scale and complexity of large outdoor LED displays are also constantly increasing, which puts higher requirements on the design, material selection, construction, and installation of steel structures.

1. Basic requirements for steel structures of large outdoor LED displays

- Safety and stability

In the steel structure design of large outdoor LED displays, safety, and stability are the primary considerations. The steel structure must be able to ensure that the display can remain stable as a whole under various harsh environmental conditions, such as strong winds, earthquakes, and other natural disasters, without collapse or serious deformation.

To achieve this goal, a detailed structural analysis is required during the design process, including the calculation of external forces such as wind loads and seismic loads to ensure the safety of the structure.

At the same time, the design of the steel structure must also avoid damaging the structural safety and use functions of the attached building to ensure harmonious coexistence between the two.

In addition, following relevant national standards, such as GB 50009 “Code for Loads on Building Structures” and GB 50011 “Code for Seismic Design of Buildings,” is an important guarantee to ensure the rationality and safety of the steel structure design.

- Durabilité

Large-scale outdoor LED display screens are exposed to wind, sun, rain, and snow for a long time, which places extremely high demands on the durability of steel structures.

Steel structure materials must have good corrosion resistance and weather resistance to resist the erosion of environmental factors and maintain long-term stable operation. To this end, when selecting materials, stainless steel with excellent weather resistance or steel with special anti-corrosion treatment should be given priority.

In addition, regular maintenance is also an important means to ensure the durability of steel structures, including checking the integrity of the coating, timely repairing damaged parts, etc., to extend the service life of the steel structure.

- Maintainability

The steel structure of the large outdoor LED display screen must also fully consider its maintainability when designing. Due to the large area and complex structure of the display screen, later maintenance and overhaul work is often difficult.

Therefore, the design of the steel structure should be convenient for maintenance personnel to enter and operate, including setting up reasonable maintenance channels, wire-passing channels, etc., so as to facilitate regular inspection, cleaning, and maintenance of the display screen and steel structure.

At the same time, the structural layout should also be reasonable to reduce unnecessary complexity and redundancy and reduce the difficulty and cost of maintenance. This can not only improve maintenance efficiency but also ensure that the display screen remains in good working condition during long-term use.

2. Selection and specifications of steel structure materials

1). Introduction to common materials

In the steel structure design of large outdoor LED display screens, it is crucial to choose the right material. Commonly used steels include square tubes, channel steels, H-shaped steels, and welded round tubes, each of which has its own unique characteristics and advantages and disadvantages.

- Square tube:

Square tubes are widely used because of their simple cross-sectional shape and easy production. Its advantage is that it has a strong bearing capacity and is suitable for structures that require higher rigidity; its disadvantage is that its torsion resistance is weaker than other profiles.

- Channel steel:

The cross-sectional shape of the channel steel is groove-shaped, with good bending resistance, and is suitable for structures that need to withstand large bending moments. However, its torsion resistance is also limited, and in some cases, there may be stress concentration problems.

- H-shaped steel:

H-shaped steel is named after its cross-sectional shape, which is similar to the English letter “H.” It has excellent bearing capacity and bending resistance. It has a large cross-sectional modulus and is lightweight, making it a preferred material in large steel structures. However, its cost may be slightly higher than that of other materials.

- Welded round tube:

Welded round tubes are made through the welding process and have good toughness and plasticity. Its cross-sectional shape is circular, which is conducive to resisting forces in various directions, and its surface is smooth and beautiful. However, the welding quality has a great influence on the performance of the round tube, and the welding process needs to be strictly controlled.

When selecting materials, comprehensive consideration must be given to the specific needs of the display screen and the site conditions.

For example, for display screens that need to withstand large wind loads and seismic loads, H-shaped steel with strong bearing capacity and good bending resistance should be selected; while for occasions with high requirements for aesthetics, materials with neat appearance such as welded round tubes can be considered.

2). Material specifications and performance requirements

After determining the type of steel, its specifications and performance requirements need to be further clarified.

- Specification expression method:

The specification expression method of each type of steel is slightly different but usually includes parameters such as length, width (or height), thickness, etc.

For example, the specifications of square tubes are often expressed as “side length × wall thickness,” and the specifications of H-shaped steel include web height, flange width, and web and flange thickness. The selection of these parameters needs to be determined based on the results of structural design and force analysis.

- Exigences de performances :

The performance requirements of steel mainly include mechanical properties, welding properties, and corrosion resistance. In terms of mechanical properties, certain indicators such as tensile strength, yield strength, and elongation must be met.

In terms of welding performance, it is necessary to ensure that the steel is easy to weld and has stable performance after welding in terms of corrosion resistance, it is necessary to select steel with corresponding corrosion resistance or take anti-corrosion measures according to the use environment. Meeting these performance requirements is the key to ensuring the safety, stability, and durability of steel structures.

3. Key points of steel structure design and construction

1). Design points

In the design process of the steel structure of a large outdoor LED display, multiple factors need to be considered comprehensively to ensure the rationality, safety, and maintainability of the structure.

- Load factor considerations:

First, the structural design must fully consider the weight of the display screen, wind loads, and possible seismic loads. These loads will directly affect the stability and safety of the structure, so it is necessary to determine the reasonable structural form and size through detailed calculations and analysis.

- Support system design:

Reasonable support system design is the key to ensuring that the structure is clearly stressed and reducing stress concentration. The support system should be able to effectively transfer and disperse the load to avoid structural damage caused by excessive local stress.

At the same time, the layout of the support system must also consider the installation and maintenance requirements of the display screen to ensure the convenience of operation.

- Space reservation:

In the design, sufficient space must be reserved to meet the installation and maintenance requirements of the display screen.

This includes reserving sufficient installation space for the display screen and setting up reasonable channels and platforms for subsequent maintenance and repair work. These reserved spaces will help improve the installation efficiency and maintainability of the display screen.

2). Construction points

The construction of steel structures is an important link to ensure that the design intent is realized. During the construction process, the quality of each link needs to be strictly controlled to ensure the stability and safety of the final structure.

- Pretreatment:

Before construction, the steel structure components need to be pre-treated by rust removal, correction, etc. Rust removal can remove rust and impurities on the surface of components, and improve the adhesion and anti-corrosion effect of coatings.

Correction can ensure that the size and shape of components meet the design requirements and reduce errors during installation.

- Welding construction:

Welding is one of the key links in steel structure construction. During the welding process, a reasonable welding sequence and process must be selected to ensure welding quality. Reasonable arrangement of the welding sequence can reduce welding deformation and stress concentration, and a suitable welding process can ensure the quality and strength of welds.

In addition, the welding process must be strictly monitored and tested to ensure that the welding quality meets relevant standards and requirements.

- Installation control:

During the installation process, dimensional accuracy must be strictly controlled to ensure that the structure is installed in place. This includes precise control of component size, installation location, connection nodes, and other aspects.

By adopting advanced measurement technology and tools, accurate monitoring and adjustment of the installation process can be achieved to ensure the stability and safety of the final structure.

At the same time, attention should be paid to safety issues during the installation process, and necessary safety measures and protective measures should be taken to ensure the safety of construction personnel.

4. Requirements for steel structures under special environments

1). Extreme climatic conditions

Under extreme climatic conditions such as strong winds, rain, and snow, the safety and stability of steel structures face severe challenges, so a series of strengthening measures need to be taken to ensure the normal operation of the structure.

- Strengthen structural support:

In strong wind areas, steel structures need to add diagonal braces or structural trusses to improve the overall stiffness and wind resistance of the structure. These diagonal braces and trusses should be accurately calculated and designed to ensure their stability and safety under extreme wind loads.

- Improve the strength of connectors:

Connectors are key components in steel structures, and their strength directly affects the overall performance of the structure. Under extreme climatic conditions, it is necessary to use connectors with higher strength and adopt more reliable connection methods, such as welding or high-strength bolt connections, to ensure the stability of the connection.

- Set expansion joints:

Considering the impact of thermal expansion and contraction on steel structures, reasonable expansion joints need to be set under conditions with extreme temperature differences.

The setting of expansion joints should be calculated and designed based on the thermal expansion and contraction coefficient of steel and the actual size of the structure to ensure that the structure can expand and contract freely when the temperature changes to avoid excessive stress and deformation.

- Waterproof and drainage measures:

In rainy and snowy weather, water or snow is easy to accumulate on the surface of steel structures, and effective waterproof and drainage measures need to be taken. For example, apply waterproof paint on the surface of steel structures, set reasonable drainage slopes and drainage ditches, etc., to ensure that the accumulated water can be discharged in time to avoid damage to the structure.

2). Earthquake-prone areas

The design of steel structures in earthquake-prone areas must follow higher seismic standards and adopt more complex seismic structural measures to ensure the safety and stability of the structure during earthquakes.

- Follow seismic design specifications:

When designing steel structures in earthquake-prone areas, it is necessary to strictly follow the relevant national seismic design specifications, such as the “Building Seismic Design Code.” These specifications specify in detail the seismic design requirements and structural measures of steel structures under different earthquake intensities.

- Adopt seismic structural measures:

In steel structure design, a variety of seismic structural measures need to be adopted to improve the seismic performance of the structure. For example, setting up seismic supports, strengthening node connections, and adopting energy-absorbing shock-absorbing devices.

These measures can effectively absorb and disperse seismic energy and reduce the degree of damage to the structure during earthquakes.

- Regularly conduct seismic performance testing:

In order to ensure the safety of steel structures in earthquakes, it is necessary to conduct regular seismic performance testing. The test content includes structural deformation, stress distribution, the status of connectors, and other aspects.

Through testing, hidden dangers and problems in the structure can be discovered in time, and corresponding measures can be taken for reinforcement and maintenance.

- Strengthen reinforcement and maintenance:

In earthquake-prone areas, steel structures may be affected by multiple earthquakes, so reinforcement and maintenance work needs to be strengthened. This includes regular inspection, maintenance, and reinforcement of the structure.

Reinforcement and maintenance can improve the seismic resistance of the structure and extend its service life. At the same time, after an earthquake, the structure must be inspected and repaired in time to ensure that it can continue to be used safely.

5. Lightning protection and grounding requirements

1). Lightning protection design

In the lightning protection design of large outdoor LED display screens, relevant national standards and industry specifications such as the “Building Lightning Protection Design Code” GB 50057 must be strictly followed to ensure the safety of the display screen and its steel structure in thunder and lightning weather. The specific design points are as follows:

- Confirmation of lightning protection level:

First, the lightning protection level needs to be determined based on the annual expected number of lightning strikes in the building where the display screen is located, the structural characteristics of the building, and the surrounding environment. This helps to determine the specific requirements of subsequent lightning protection measures.

- Lightning protection device setting:

According to the lightning protection level, lightning protection devices such as lightning rods and lightning strips are set on the top or near the steel structure of the display screen.

The length and number of lightning rods need to be calculated and designed according to the size and height of the display screen to ensure that they can effectively protect the display screen from direct lightning strikes.

At the same time, lightning strips need to be set along the top or side of the steel structure to form a continuous conductive path to lead lightning into the ground.

- Power supply and signal line protection:

Lightning arresters are installed on the power line and signal line of the display screen to prevent lightning from invading the inside of the display screen through the line.

The power lightning arrester needs to be installed in the distribution box of the display screen, while the signal lightning arrester needs to be selected and installed according to the type of signal interface.

2). Grounding requirements

Grounding is an important link in the lightning protection system, which is directly related to whether the lightning current can be quickly and safely introduced into the earth. Therefore, in the grounding design of large outdoor LED display screens, special attention should be paid to the following points:

- Reliable connection:

The steel structure of the display screen needs to be reliably connected to the building’s grounding system. This is usually achieved by welding or bolting to ensure good contact and low resistance at the connection.

At the same time, attention should also be paid to the material and cross-sectional area of the grounding wire to meet the requirements of the current transmission.

- Grounding resistance control:

Grounding resistance is an important indicator for measuring the performance of the grounding system. According to relevant standards, the grounding resistance of outdoor LED display screens is generally required to be less than 10 ohms. If this requirement is not met, additional measures, such as artificial grounding grids, should be taken to improve it.

- Contrôle régulier :

The grounding system needs to be regularly inspected for integrity and effectiveness. This includes testing and recording the connection status of the grounding wire, the grounding resistance value, etc. Once a problem is found, timely measures should be taken to repair or replace it to ensure the reliability of the grounding system.

Conclusion

In summary, the requirements for the steel structure of large outdoor LED display screens are a systematic project involving material selection, structural design, construction and installation, maintenance and other aspects.

Only by strictly following the relevant standards and specifications can the stability and safety of the display screen be ensured, providing strong support for the city’s image display and cultural communication.

Enfin, si vous souhaitez en savoir plus sur les écrans LED, veuillez nous contacter.