Introduction

L'environnement extérieur est complexe et changeant, en particulier les facteurs météorologiques, qui représentent un défi majeur pour la performance de l' Affichage LED.

Parmi eux, la performance d'étanchéité est l'un des indicateurs importants pour mesurer la qualité des écrans LED extérieurs. Alors, votre écran LED extérieur est-il vraiment étanche ? Comment est-il étanche ? Cet article vous le dira en détail.

1. Une brève introduction à la conception étanche de l'affichage LED extérieur

1). Norme de qualité d'étanchéité

En ce qui concerne l'étanchéité des écrans LED extérieurs, il convient de mentionner la norme de protection IP. Cette norme est utilisée pour mesurer les capacités d'étanchéité à la poussière et à l'eau de l'équipement.

Il est composé de deux chiffres. Le premier chiffre indique le degré d'étanchéité à la poussière et le deuxième le degré d'étanchéité à l'eau.

- Niveau d'étanchéité à la poussière :

Plus le chiffre est élevé, plus l'effet anti-poussière est efficace. Par exemple, le niveau 6 signifie que la poussière est complètement empêchée de pénétrer et qu'aucune poussière ne peut pénétrer à l'intérieur.

- Niveau d'étanchéité :

Plus le chiffre est élevé, plus l'étanchéité est élevée. Comme IP65, cela signifie que l'équipement peut empêcher l'entrée d'eau pulvérisée. Quelle que soit la direction d'où provient l'eau pulvérisée, il n'y a aucun problème. IP66 est encore plus puissant et ne craint pas les grosses vagues.

Plus précisément, la norme de test IP65 stipule que l'équipement doit être capable de résister au test de pulvérisation d'eau simulée pour garantir que l'eau ne pénètre pas. IP66 exige que l'appareil résiste à l'impact de grosses vagues tout en restant étanche.

Pour les écrans LED extérieurs, IP65 est un niveau d'étanchéité courant, mais s'il s'agit d'un écran en bord de mer ou d'un endroit où il pleut fréquemment, un niveau d'étanchéité plus élevé, tel que IP66, peut être choisi.

2). Caractéristiques de conception

La conception étanche des écrans LED extérieurs est en fait assez intéressante. Laissez-moi vous en parler brièvement :

- Matériau de la coque :

La coque de l'écran est généralement constituée de matériaux spéciaux imperméables et anti-poussière, tels que l'alliage d'aluminium. Ces matériaux sont non seulement solides et durables, mais ont également d'excellents effets imperméables et ne craignent ni le vent ni la pluie.

- Traitement des coutures :

Les coutures de la coque sont la clé de la conception étanche. En général, des produits d'étanchéité ou des bandes d'étanchéité étanches sont utilisés pour sceller afin de garantir que l'eau ne pénètre pas dans les interstices. Lors de l'installation, les ouvriers vérifieront soigneusement chaque couture pour s'assurer qu'il n'y a aucun risque.

- Étanchéité des circuits imprimés :

Le circuit imprimé est le cœur de l'écran, il faut donc prendre des mesures d'étanchéité. Certains circuits imprimés seront recouverts d'une couche de revêtement imperméable, tout comme l'application d'une couche imperméable sur le circuit imprimé.

Certains installeront également un couvercle étanche sur le circuit imprimé afin que même si de l'eau éclabousse le circuit imprimé, cela ne provoque pas de court-circuit ou de dommages.

- Conception de fuite :

Enfin, certaines fuites seront conçues au bas ou sur le côté de l'écran. De cette façon, si de l'eau s'infiltre, elle peut être évacuée à temps par la fuite et ne s'accumulera pas dans l'écran et ne causera pas de dommages.

En général, la conception étanche des écrans LED extérieurs est assez astucieuse : du choix des matériaux au traitement des coutures en passant par l'étanchéité des circuits imprimés et la conception des fuites, tout est soigneusement étudié. De cette façon, nous pouvons voir un affichage clair et lumineux par tous les temps !

2. Quel est le test d'étanchéité et la certification des écrans LED extérieurs ?

1). Méthode d'essai

Le test d'étanchéité d'un écran LED extérieur permet de savoir s'il peut résister au vent et à la pluie. La méthode de test est assez intéressante, laissez-moi vous dire :

1.1). Simuler l'environnement extérieur :

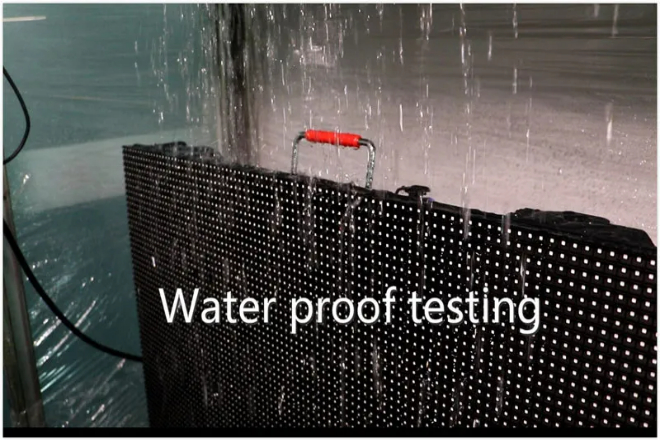

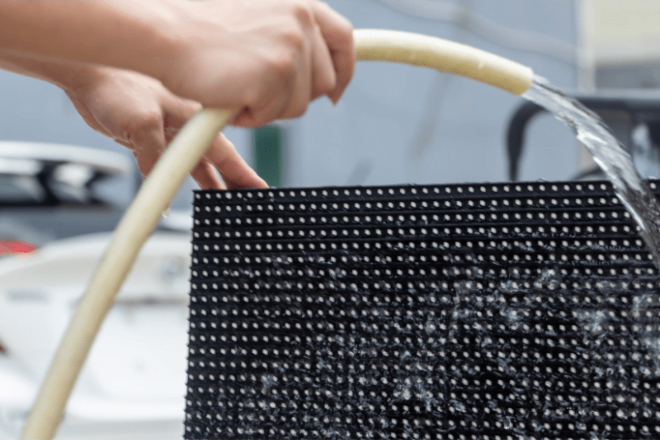

- Pulvérisation d'eau de pluie et de neige :

Tout comme pour donner un bain à l'écran, utilisez une buse pour simuler la pluie et la neige pour voir si l'eau s'infiltre. Je l'ai pulvérisé pendant longtemps juste pour m'assurer qu'il pouvait fonctionner normalement, même sous de fortes pluies et de la neige.

- Test d'immersion :

Trempez l'écran dans l'eau, comme s'il était tombé accidentellement dans l'eau. Laissez-le tremper un moment pour voir si l'eau pénètre à l'intérieur et s'il peut encore s'allumer.

1.2). Test en environnement poussiéreux :

Placez l'écran dans un endroit poussiéreux pour voir s'il est bien scellé. Si la poussière ne peut pas pénétrer, cela signifie que l'étanchéité est plutôt bonne.

1.3). Test du caisson de plongée :

Il existe une méthode encore plus impitoyable : mettre l'écran dans un caisson de plongée, le plonger à une certaine profondeur et le laisser tremper pendant une longue période. C'est comme si l'écran travaillait sous l'eau pour voir s'il peut y résister.

2). Processus de certification

Après le test, vous devez obtenir un certificat pour prouver que l'écran est réellement étanche. Le processus de certification est également très simple :

- Test selon la norme :

Il existe une norme internationale appelée IEC 60529, qui est testée selon cette norme. L'organisme de test enregistrera tous les résultats des tests pour garantir que le test est équitable.

- Obtenez un certificat après avoir réussi le test :

Si l'écran d'affichage passe tous les tests, vous pouvez obtenir un certificat de certification du niveau de protection IP. Par exemple, IP65 signifie que l'écran d'affichage est étanche à la poussière et à l'eau, et qu'il ne craint ni la pluie ni la neige. IP66 est encore plus puissant et ne craint pas les grosses vagues.

En général, le test d'étanchéité et la certification des écrans d'affichage LED extérieurs visent à vérifier s'ils peuvent résister à l'épreuve de diverses conditions météorologiques défavorables et à obtenir un certificat pour le prouver. De cette façon, tout le monde sera plus rassuré lors de l'achat.

3. Quelles sont les performances d’étanchéité et les applications pratiques des écrans d’affichage LED extérieurs ?

1). Performances d'étanchéité

Les performances d'étanchéité de écrans d'affichage LED extérieurs est la clé pour garantir qu'ils fonctionnent normalement dans diverses conditions météorologiques défavorables.

Les écrans d'affichage LED extérieurs qualifiés peuvent maintenir de bonnes conditions de travail les jours de pluie et pendant le nettoyage quotidien et ne causeront pas de problèmes tels que des images floues, des scintillements ou même des courts-circuits dus à l'infiltration d'eau.

Pour les écrans d'affichage avec des niveaux d'étanchéité plus élevés, ils peuvent même fonctionner de manière stable dans des conditions météorologiques extrêmes telles que de fortes pluies et des typhons.

Ces écrans d'affichage utilisent généralement des technologies d'étanchéité avancées, telles que des revêtements imperméables, des produits d'étanchéité imperméables, des coques imperméables, etc., pour garantir que l'humidité ne peut pas pénétrer à l'intérieur de l'écran d'affichage, protégeant ainsi les composants électroniques internes contre les dommages.

Plus précisément, les écrans LED extérieurs avec un indice d'étanchéité plus élevé, tel que IP65 ou IP66, peuvent empêcher complètement la poussière de pénétrer et peuvent résister à l'impact des projections d'eau ou des grosses vagues venant de toutes les directions.

Ces solides performances d'étanchéité rendent les écrans LED extérieurs largement utilisés dans la publicité extérieure, les affichages d'informations et d'autres domaines.

2). Scénarios d'application pratique

Les performances d'étanchéité des écrans LED extérieurs leur permettent de jouer un rôle important dans divers scénarios d'application pratiques. Voici quelques scénarios d'application typiques :

2.1). Publicité extérieure et affichage d’informations :

Dans les lieux publics tels que les blocs commerciaux, les places et les gares, les écrans LED extérieurs sont largement utilisés pour la publicité et l'affichage d'informations.

Ils peuvent diffuser diverses publicités commerciales, informations publiques, prévisions météorologiques et autres contenus en temps réel, attirer l'attention des passants et améliorer l'efficacité de la diffusion des informations.

2.2). Enseignes et panneaux d’affichage dans les lieux publics :

Dans les lieux publics tels que aéroports, gares, hôpitaux, et dans les écoles, les écrans LED extérieurs sont utilisés comme panneaux et tableaux d'affichage.

Ils peuvent afficher clairement diverses instructions, annonces, etc., offrant ainsi un confort aux passants. En même temps, grâce à leurs excellentes performances d'étanchéité, ces écrans peuvent également fonctionner de manière stable pendant une longue période dans des environnements extérieurs.

2.3). Diffusion en direct d'événements de grande envergure tels que des événements sportifs et des concerts :

Sur les lieux d’événements de grande envergure tels que des sports événements et concerts, les écrans LED extérieurs sont utilisés comme dispositifs d'affichage pour les diffusions en direct.

Ils peuvent diffuser la situation en direct du match, les images du concert et d'autres contenus en temps réel, offrant au public une expérience de visionnage immersive.

En raison de l'environnement extérieur complexe et changeant, ces écrans doivent avoir d'excellentes performances d'étanchéité pour assurer un fonctionnement normal dans des conditions météorologiques défavorables telles que les jours de pluie.

De plus, les écrans LED extérieurs sont largement utilisés dans l’éclairage des bâtiments, les représentations sur scène et d’autres domaines.

Avec l'avancement continu de la technologie et le développement continu du marché, les performances d'étanchéité des écrans LED extérieurs seront encore améliorées, offrant un support solide pour les applications dans davantage de domaines.

4. Quelles sont les mesures pour améliorer les performances d’étanchéité des écrans LED extérieurs ?

L'amélioration des performances d'étanchéité des écrans LED extérieurs est cruciale en raison de leur environnement d'utilisation particulier. Voici quelques mesures efficaces pour améliorer les performances d'étanchéité des écrans LED extérieurs :

1) Choisissez des matériaux et des technologies imperméables de haute qualité

- Matériaux de la coque :

Choisissez des matériaux imperméables, résistants à la corrosion, aux UV et présentant d’autres caractéristiques, telles que l’alliage d’aluminium, l’acier inoxydable, etc.

Ces matériaux peuvent non seulement résister efficacement à l’érosion du vent et de la pluie, mais également réduire le phénomène de vieillissement causé par une exposition prolongée au soleil.

- Revêtement et produit d'étanchéité imperméables :

Appliquez un revêtement imperméable ou utilisez un produit d'étanchéité de haute qualité pour sceller les éléments clés de l'écran, tels que les circuits imprimés et les interfaces. Le revêtement imperméable peut former un film protecteur pour bloquer efficacement l'intrusion d'humidité, tandis que le produit d'étanchéité imperméable peut garantir que les espaces entre les composants sont efficacement remplis et scellés.

2). Contrôler strictement le processus d'étanchéité lors de l'assemblage

- Équipe d'installation professionnelle :

Sélectionnez une équipe d'installation possédant une riche expérience et une technologie professionnelle pour assembler et installer l'écran. Ils peuvent formuler un plan d'installation raisonnable en fonction des caractéristiques et de l'environnement d'utilisation de l'écran pour garantir que chaque étape répond aux exigences d'étanchéité.

- Processus de scellement :

Lors du processus d'assemblage, accordez une attention particulière à l'étanchéité des joints et des raccords. Utilisez des outils et des méthodes d'étanchéité professionnels pour vous assurer que chaque espace est efficacement rempli et scellé.

En particulier, des trous de drainage doivent être placés au fond et sur les côtés de l'écran afin que l'eau de pluie ou de neige puisse être évacuée à temps lorsqu'elle s'infiltre.

- Contrôle de la qualité:

Une fois l'assemblage terminé, un contrôle qualité complet est effectué pour s'assurer que chaque composant est installé en place et que l'effet d'étanchéité est bon. Pour tout problème détecté, la rectification et le traitement doivent être effectués en temps opportun.

3). Vérifiez et maintenez régulièrement les performances d'étanchéité

- Contrôle régulier :

Vérifiez régulièrement le boîtier de l'écran, le circuit imprimé, l'interface et les autres pièces clés pour détecter tout dommage ou vieillissement. Réparez ou remplacez tout problème détecté en temps opportun.

- Nettoyage et entretien:

Nettoyez régulièrement la poussière et les débris sur la surface de l'écran pour assurer une bonne dissipation de la chaleur. Utilisez un chiffon de nettoyage doux ou une éponge pour essuyer et évitez d'utiliser des détergents contenant de l'alcool ou des produits chimiques.

- Test d'étanchéité :

Effectuez régulièrement des tests d'étanchéité pour simuler des conditions extérieures telles que la pluie et la neige, et arrosez ou pulvérisez l'écran. Grâce aux tests, les problèmes potentiels d'étanchéité peuvent être détectés et traités en temps opportun.

4). Prendre des mesures de protection appropriées en cas de conditions météorologiques extrêmes

- Housse en tissu imperméable :

Dans des conditions météorologiques extrêmes telles que de fortes pluies et des typhons, l'écran peut être recouvert d'un tissu imperméable pour réduire l'impact direct de la pluie et du vent.

- Protection contre les coupures de courant :

Dans des conditions météorologiques extrêmes, si l'écran risque d'être victime d'une infiltration d'eau ou d'un court-circuit, l'alimentation électrique doit être coupée à temps pour éviter tout dommage à l'équipement ou tout accident de sécurité.

- Mesures d’urgence :

Élaborez un plan d'urgence afin de pouvoir réagir et gérer rapidement la situation en cas de panne de l'écran. Le plan doit inclure les procédures de dépannage, les coordonnées de maintenance, la préparation d'un écran de rechange, etc.

Conclusion

En résumé, les performances d’étanchéité des écrans LED extérieurs constituent la garantie clé de leur fonctionnement stable dans des environnements extérieurs difficiles.

Grâce à une conception raisonnable, des tests rigoureux, une application approfondie et une maintenance régulière, nous pouvons garantir que l'affichage LED extérieur présente de bonnes performances d'étanchéité et fournit un support fiable pour la transmission d'informations urbaines et l'affichage publicitaire.

Enfin, si vous souhaitez en savoir plus sur les écrans LED, veuillez nous contacter.