Introduction

When installing Affichage LED screens, the installer may ask you whether you need to do edge treatment. Edge treatment is very easy to overlook during the installation of LED display screens. So some people will ask: Do LED display screens really need to be edged when installed?

In fact, this depends on personal ideas, not a rigid requirement. This article will tell you the reasons in detail.

1. What is the role and significance of edge treatment of LED display screens?

The edge treatment of LED display screens may sound a bit professional, but in fact, it is like a protective case we put on the screen of our mobile phone, which is both practical and beautiful. Next, let’s talk about the unknown benefits of edge treatment.

First, let’s talk about the protection module. LED display screens are made up of small modules. These modules are like the “heart” of the display screen, which is particularly delicate. If you accidentally touch or knock it, you will feel distressed for a while.

The edge treatment is like putting a layer of armor on these “hearts,” which can resist those “accidental attacks” from the outside world, such as accidental bumps, wind, and rain, which can keep the display screen safe and sound and last longer.

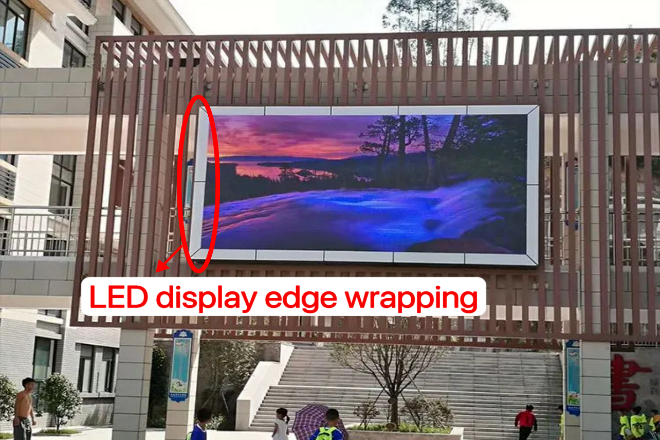

Let’s take a look at the issue of aesthetics. Think about it: if the LED display screen is just placed there bare, don’t you always feel that something is missing?

The edge treatment is like tailoring a set of “clothes” for the display screen, which not only makes it look more fashionable and classy but also integrates with the surrounding environment and looks particularly harmonious.

For example, in a commercial district, a uniquely designed edge can make the display screen an eye-catching highlight and bring more traffic to the business.

Speaking of stability, this is a great contribution to the edge treatment. LED display screens are usually spliced together by many modules. If there is no stable “frame” to fix them, then the wind blows, and the hand touches them, won’t they fall apart?

The edge treatment is like adding a “tightening spell” to the display screen, allowing it to stay there steadily. Whether it is windy or rainy, it can maintain a stable display effect.

Finally, we have to mention the functional improvement brought by the edge treatment. Did you know? Some edge designs are not just good-looking. They also hide a lot of “little tricks”! For example, some edge designs are embedded with mounting brackets, making the installation and removal of the display screen particularly convenient。

Some are designed with heat dissipation holes to help the display screen dissipate heat and prevent it from “striking” due to overheating. These designs not only make the display screen more convenient to use but also greatly improve its stability and reliability.

2. In which scenes does the LED display screen need to be edge-treated?

Edge treatment for LED display screens is a very interesting topic. Many of the shiny display screens we usually see in shopping malls, squares, and even at home have been carefully edge-treated. So, in which scenes does the LED display screen particularly need this kind of “dressing”? Let’s talk about it together.

1). Indoor environment:

Indoors, LED display screens are a good thing that can be “matched” with everything. Wall-mounted, column-mounted, hanging, or you can install it however you want. However, don’t underestimate the edge treatment behind these installation methods.

For example, with a wall-mounted display, you don’t want the display to be hung on the wall very abruptly, right? At this time, an edging that matches the color and style of the wall can make the display and the wall “match,” which is both beautiful and practical.

Let’s talk about column-mounted and hanging-mounted displays. Displays installed in these two ways are usually tall and majestic and are the “face value” in commercial spaces. However, you also have to consider safety issues!

A stable edging can not only fix the display but also prevent it from falling and hitting people. Moreover, a good edging design can also enhance the overall visual effect so that customers will be attracted at first sight.

Of course, factors such as indoor light and viewing distance must also be taken into account. Proper edging can reduce reflection and glare, making the audience more comfortable.

2). Outdoor environment:

The outdoor environment is much more complicated than the indoor environment. Wind, rain, thunder… these are the “natural enemies” of display screens. Therefore, the edging of outdoor display screens must be more particular.

First of all, it must be windproof and rainproof. The edging must be done tightly to prevent rain from seeping in and “damaging” the display screen. Moreover, the edging material must be corrosion-resistant and able to withstand wind and sun.

Lightning protection is also a big deal. Especially in areas with frequent thunderstorms, the edging of the display screen must be well protected against lightning to ensure that the display screen can safely survive every thunderstorm night.

Of course, outdoor display screens must also stand the test of time. If the edging is well handled, the display screen can be used longer and bring more benefits to the merchants.

3). Special shape screens:

In addition to conventional rectangular display screens, there are many special shape display screens, such as circular screens, borderless designs, etc. The edging treatment of these display screens is even more challenging.

The edging of the circular screen must “hide” the edges and corners of the rectangular module, making the display screen look like a perfect circle. This is a test of the designer’s skills.

The borderless design of the display screen requires exquisite craftsmanship to achieve. The edging must be concealed and firm, and it must be coordinated with the overall style of the display screen. Once such a display screen is unveiled, it will definitely become the focus of everyone’s attention.

3. How do you choose the edge material of the LED display screen?

Choosing the edge material of the LED display screen is actually quite interesting. Just like when we usually choose clothes, we have to look at the occasion, style, and budget, right?

Then let’s talk about this today and see which materials are suitable for our LED display screen to “wear” the right “outer coat.”

1). Stainless steel:

Stainless steel is not uncommon. Many of the pots and pans we usually use are made of it. Why choose it to edge the LED display screen? First of all, it is corrosion-resistant. Whether it is outdoor wind and rain or an indoor humid environment, it can cope with it easily and is not afraid of rust. In addition, it is easy to clean. If it is dirty, just wipe it with a cloth, and it will be clean, just like a new one.

The most important thing is that it is beautiful and generous. The silver glittering luster is high-end and suitable for various occasions, especially outdoor and large commercial places. It is like putting a “suit” on the display screen, which looks particularly classy.

2). Alliage d'aluminium :

Aluminum alloy is much lighter than stainless steel, easy to carry and install. Moreover, it looks fashionable, and the metal texture makes people like it at first sight. Although the corrosion resistance may be slightly worse, it is completely fine for indoor or semi-outdoor environments.

Just like the casual clothes we usually wear, they are comfortable and beautiful and suitable for various relaxed occasions, such as shopping malls, hotels, and conference rooms.

3). Plastic:

Plastic is more affordable, cheap, and easy to process. It can be made into any shape you want. However, it also has disadvantages, that is, it is less durable and easy to age and deform. So, if the budget is limited or it is just for temporary use, plastic edging is also a good choice.

Just like the daily clothes we usually wear, although they are not so high-end, they are comfortable to wear and affordable.

4). Other materials:

In addition to the above, there are some other materials, such as aluminum-plastic panels. This thing is amazing. It combines the advantages of aluminum and plastic.

It is light and corrosion-resistant and can be made into various colors and patterns, just like what we usually say, “all-match,” it can be matched with any style and any occasion.

If you want both beauty and durability and want to control costs, then aluminum-plastic panels are definitely a good choice.

5). Tips for selecting materials

When choosing edge materials, we have to consider them comprehensively. First of all, we have to look at the environment used, whether outdoors or indoors, wet or dry, to determine the corrosion resistance and weather resistance of the material.

Then, we have to look at the overall style, whether we want a high-end atmosphere, fashionable and lightweight, or economical and affordable. Of course, budget is also an important factor, and we have to choose according to our wallet.

Finally, we have to consider the difficulty and cost of processing. Don’t choose a good material, but it will be difficult to process, and the cost will exceed.

4. Installation and maintenance of LED display edge packaging

The installation and maintenance of LED display edge packaging is really a big job, but don’t worry, let’s have a down-to-earth explanation today to make it easy for you!

1). Installation steps, step by step; don’t panic!

1.1). Measure the size accurately!

First, you have to take out your tape measure and carefully measure the length, width, and height of the display screen. The size must be measured accurately. Otherwise, it will be troublesome if the edge is too big or too small.

After measuring, cut the edge material according to the size, and remember to leave some margin in case it needs to be adjusted.

1.2) You must prepare tools and materials!

Next, take out your screwdriver, wrench, tape measure, and other tools, as well as edge materials, screws, and fasteners. All accessories must be prepared so as not to be short of this or that.

1.3). Anti-vibration treatment, be careful!

Anti-vibration is a big deal during installation. You have to find a way to reduce the vibration of the display screen during transportation and installation, such as using a shock-absorbing pad, spring, etc. In addition, the display screen must be fixed firmly, and don’t let it shake.

1.4). Edge installation, be meticulous!

Now, it’s the turn of the edge. You have to bend and shape the edging material according to the shape of the display screen and then fix it to the frame of the display screen with screws or fixings.

When fixing, make sure there is no gap between the edging and the display screen, and the fixings must be evenly distributed so that the edging is stable and looks good.

1.5). Check and adjust carefully!

After the installation, don’t rush to leave; you have to check it carefully. Check whether the edging is installed firmly and there is no looseness or falling off. Look again to see if there is any gap or unevenness between the edging and the display screen.

If there is, you have to adjust it. Make sure that the edging will not affect the display effect or the heat dissipation performance of the display screen.

2). Maintenance points:

2.1). Clean regularly; it must be clean!

The edging also needs to be cleaned regularly. Otherwise, dust and dirt will pile up on it; how ugly! Just take a soft cloth or sponge and wipe it gently. Remember not to use highly corrosive detergents; otherwise, it will be troublesome if the edging is corroded.

2.2). Check the connection; it must be firm!

Regularly check whether the connection between the edge and the display is firm; this is a big deal. If you find that the connection is loose or the screws are off, you must tighten or replace the screws quickly. Otherwise, if the edge falls off one day, it will be embarrassing.

2.3). Avoid external force; be careful!

In daily life, be careful not to let external forces damage the edge. If the edge is damaged, you must repair or replace it quickly; otherwise, it will affect the display’s effect and the safety of the display.

2.4). Regular inspection and maintenance; be diligent!

In addition to daily cleaning and inspection, you must also regularly conduct more comprehensive inspections and maintenance of the LED display and edge. For example, check the display effect, heat dissipation performance, and power supply stability of the display.

If you find a problem, you must quickly contact a professional for repair or replacement. Don’t be lazy. Otherwise, it will be troublesome if there is a problem at that time.

Conclusion

In summary, whether the LED display needs to be edge-wrapped during installation is not a general question but needs to be considered comprehensively according to the specific application scenario, installation environment, and characteristics of the display.

Edge-wrapping can not only provide effective physical protection for the display, improve the overall aesthetics and stability, but also extend the service life of the display to a certain extent. Therefore, in most cases, edge-wrapping is necessary and beneficial.

Enfin, si vous souhaitez en savoir plus sur les écrans LED, veuillez nous contacter.