Introduction

In the modern information society, Afficheurs LED have become an important tool for transmitting information and displaying images.

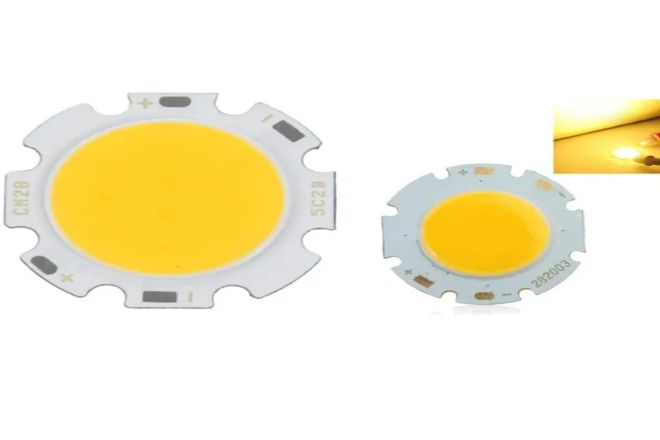

The quality of the LED display, the core component of the LED display, directly affects the overall performance and service life of the display. Therefore, it is very important to learn to identify the quality of LED display beads.

Step 1: Look at the appearance

When we get a batch of LED display beads, the first thing we see is their appearance. High-quality LED lamp beads should have a neat and flawless appearance, a fine packaging process, and no obvious dirt, scratches, or oxidation. At the same time, the packaging form of the same batch of lamp beads should be consistent to avoid mixing.

In terms of packaging technology, we also need to pay attention to the welding of leads. High-quality LED lamp beads, their lead welding should be solid and reliable, without virtual welding and false welding. In addition, the colloidal part should also be free of bubbles, cracks, and other defects, and the color should be uniform.

Step 2: Look at the brightness

When observing the brightness of the LED display beads, you need to pay attention to the following points:

Ambient lighting: Ensure that the ambient lighting conditions are consistent when observing the brightness. Different ambient lighting will affect the perception of LED brightness. In order to accurately compare the brightness of different lamp beads, it is best to observe under the same lighting conditions.

Observation angle: The luminous intensity of the LED may change at different observation angles. Therefore, when comparing the brightness, it is necessary to ensure that the observation angle is consistent to obtain accurate comparison results.

Visual adaptability: When the human eye observes light sources of different brightness, it takes a certain amount of time to adapt. When comparing the brightness of different LED lamp beads, give the eyes enough time to adapt to ensure an accurate perception of brightness differences.

Comparison reference: In order to more accurately evaluate the brightness of the LED, references of known brightness can be used for comparison. This can help you better judge the brightness level of the LED.

Consider the color temperature and color rendering index of LED: in addition to brightness, the color temperature and color rendering index of LED will also affect its luminous effect. When evaluating brightness, these factors should also be considered to obtain more comprehensive evaluation results.

Use professional tools: If you need more accurate brightness measurement, you can use professional measuring equipment such as photometers or integral balls. These devices can provide accurate brightness values to help you compare the brightness of different LED beads more accurately.

Step 3: Look at the chip

When looking at the chip of LED display beads, there are a few points to pay attention to:

- Chip brand and source:

Chip is the core component of LED lamp beads, and its quality and performance directly affect the performance of all the lamp beads. Therefore, we should first pay attention to the brand and source of the chip. Well-known brands usually have better quality assurance and more stable performance.

- Chip size:

Generally speaking, the larger the chip size, the larger its luminous area, and the luminous fold and brightness will be improved accordingly. Therefore, when comparing different LED lamp beads, you can pay attention to the size of their chips.

- Luminous efficiency:

Luminous efficiency is one of the important indicators to measure the performance of LED chips. It represents the luminous fold at unit power. The higher the luminous efficiency, the more light the LED emits at the same power and the better the energy-saving effect.

- Wavelength consistency:

For applications that require color consistency (such as displays), wavelength consistency is an important parameter. The LED chip with good wavelength consistency emits a more uniform color of light.

- Performances de dissipation thermique :

LED will generate heat when working. If the heat dissipation is not good, it will cause the temperature of the chip to rise and affect its performance and life. Therefore, when looking at the chip, you can pay attention to its heat dissipation structure design and material selection.

Step 4: Look at the process

When checking the packaging process of LED display lamp beads, you should pay attention to the following details:

- Colloid consistency:

The encapsulated LED lamp bead colloid should be consistent, and there should be no obvious differences, such as uneven color or bubbles. The consistency of the colloid affects not only the appearance but also the performance and stability of the LED.

- Quality of solder joints:

The solder joint is a very critical part of the packaging of LED lamp beads. The quality of the solder joints directly affects the conductivity and stability of the LED. Good solder joints should be full, smooth, and free of virtual welding and fake welding. If the solder joint is not full, and there are burrs or bubbles, it may affect the performance of the LED.

- Pin flatness:

The pin is the part where the LED lamp bead is connected to the external circuit. The flatness of the pin is very important for the installation and welding of the LED. The pins should be flat and evenly spaced so as to ensure that the LED can have good contact with the circuit board during installation and improve the welding quality.

- Encapsulation size:

The package size of LED lamp beads should meet the specifications. If the size is too large or too small, it may lead to installation difficulties or unstable performance. Therefore, when checking the packaging process, attention should be paid to whether the size of the LED lamp beads is accurate.

- Cleanliness:

The packaging process should be kept clean to prevent dust, impurities, and other pollutants from entering the LED lamp beads. Therefore, when checking the packaging process, attention should be paid to whether the surface of the LED lamp beads is clean and free of impurities.

Conclusion

The above are the four steps to identify the quality of LED display beads. Have you learned it?

Si vous souhaitez en savoir plus sur les écrans LED, merci de nous contacter!