Introduction

Dans le monde d’aujourd’hui, où la technologie d’affichage numérique évolue chaque jour, Affichage LEDLes LED sont largement utilisées dans divers domaines tels que la publicité, les scènes, les stades, les panneaux de signalisation, etc., avec leurs avantages tels qu'une luminosité élevée, une longue durée de vie, des économies d'énergie et la protection de l'environnement.

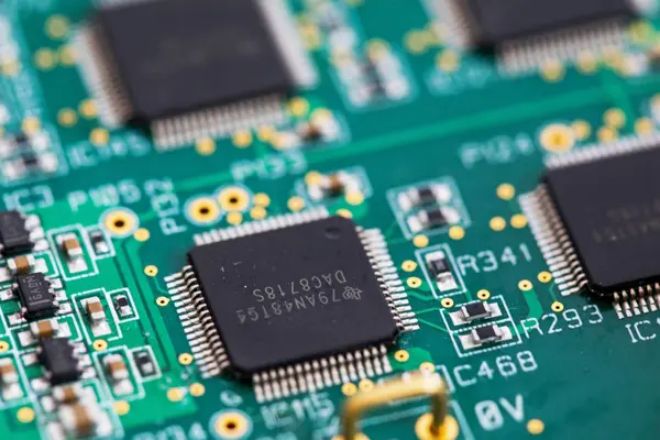

Cependant, derrière ces effets d'affichage impressionnants et ces nombreux scénarios d'application, il existe un support technique clé : le circuit intégré (CI). En tant que composant principal des écrans d'affichage à LED, le CI pilote et contrôle non seulement l'allumage et l'extinction de chaque pixel LED, mais est également responsable de la transmission et du traitement des données, ce qui est la clé du fonctionnement normal et efficace des écrans d'affichage à LED.

1. Quel est le circuit intégré de l'écran d'affichage LED

Le circuit intégré de l'écran LED, c'est-à-dire le circuit intégré (Integrated Circuit), est un composant essentiel indispensable de l'écran LED. Il est comme le « cerveau » et le « cœur » de l'écran d'affichage, contrôlant l'allumage et l'extinction de chaque pixel LED et garantissant que l'écran d'affichage peut fonctionner normalement et efficacement. Voici les caractéristiques fonctionnelles du circuit intégré de l'écran LED :

- Réception et traitement des données

Imaginez que vous envoyez une vidéo à l'écran LED avec votre téléphone portable. Tout d'abord, les données vidéo doivent être reçues par le circuit intégré de l'écran LED via une interface appelée « broche d'entrée de données (DIN) ». En même temps, afin de garantir que la vidéo puisse être lue sans problème, il existe une interface appelée « broche d'entrée d'horloge (CLK) » qui reçoit quelque chose appelé « signal d'horloge », qui est comme un métronome, indiquant au circuit intégré quand recevoir de nouvelles données.

- Verrouillage et transmission de données

Lorsque le circuit intégré reçoit ces données, il ne les affiche pas immédiatement à l'écran, mais les « verrouille » d'abord pour garantir que les données ne seront pas perdues ou erronées. Ce processus revient à placer des fichiers importants dans un dossier sécurisé. Ensuite, le circuit intégré transmet ces données à chaque pixel de l'écran LED d'une manière spécifique.

- Contrôle de sortie

Lorsque les données sont prêtes à être affichées à l'écran, le circuit intégré contrôle la sortie des données via une interface appelée « broche d'activation de sortie (OE) ». Vous pouvez considérer cette interface comme un interrupteur. Lorsqu'il est activé, les données s'écoulent hors du circuit intégré comme de l'eau et s'affichent sur l'écran LED.

- Contrôle de haute précision

Mais il ne suffit pas d'afficher les données. Il faut également s'assurer que l'image est suffisamment claire et que les couleurs sont suffisamment vives. À ce stade, la fonction de contrôle de haute précision du circuit intégré est très utile. Il peut contrôler avec précision la luminosité et la couleur de chaque pixel LED, tout comme un peintre mélangeant les couleurs sur une palette. De cette façon, que vous souhaitiez regarder des films haute définition ou de magnifiques publicités, l'écran LED peut les présenter parfaitement.

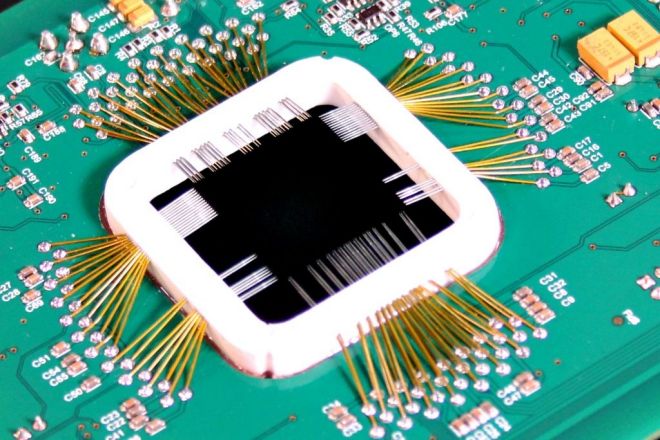

2. Types de circuits intégrés pour écrans LED

Il existe de nombreux types de circuits intégrés pour les écrans LED, qui peuvent être grossièrement résumés dans les catégories suivantes en fonction de différentes fonctions et utilisations :

- Circuit intégré du pilote

Le circuit intégré de commande est un composant clé de l'affichage LED, chargé de convertir le signal électrique d'entrée en un signal de courant capable de piloter les perles de lampe LED. Ils ont généralement des caractéristiques de sortie à courant constant ou à tension constante pour assurer la stabilité et la cohérence de l'affichage LED.

Exemple : MBI5024, il s'agit d'une puce de pilote de LED avec un verrou de décalage de 16 bits qui peut contrôler l'allumage et l'extinction de 16 ampoules LED au maximum. Elle fonctionne par entrée de données série, transmission de données de contrôle du signal d'horloge et verrouillage, et contrôle enfin l'allumage et l'extinction des ampoules LED via des ports de sortie parallèles.

- Circuit intégré de contrôle

Le circuit intégré de contrôle est principalement chargé de recevoir les signaux de données de l'extérieur, de les décoder et de les traiter, puis de les transmettre au circuit intégré de commande pour contrôler le contenu d'affichage de l'écran LED.

Exemple : TPIC6B595, il s'agit d'une puce de pilote d'affichage LED à entrée série et sortie parallèle, adaptée au pilotage d'affichages LED simples, tels que des tubes numériques à 7 segments, etc.

- Circuit intégré de gestion de l'alimentation

Le circuit intégré de gestion de l'alimentation est principalement utilisé pour l'alimentation et la gestion des écrans d'affichage à LED afin de garantir un fonctionnement stable de l'écran d'affichage. Ils ont généralement des fonctions telles que la conversion de puissance, le réglage de la tension, la protection contre les surintensités et les surtensions.

Exemple : certaines puces de pilote à courant constant peuvent garantir que le courant de sortie reste constant et n'est pas affecté par la tension d'entrée et la température, ce qui est crucial pour la luminosité et la stabilité des couleurs des écrans d'affichage LED.

- Circuit intégré d'interface

L'interface IC est utilisée pour réaliser la communication entre les écrans d'affichage LED et les périphériques ou systèmes externes, tels que la réception de signaux de commande, la transmission de données d'affichage, etc.

Exemple : MAX7219/MAX7221, qui est un pilote d'écran d'affichage LED couramment utilisé avec une fonction en cascade, peut connecter plusieurs pilotes via une interface série pour obtenir un contrôle d'écran d'affichage LED à grande échelle.

- Circuit intégré à fonction spéciale

Le circuit intégré à fonction spéciale est conçu pour certains besoins particuliers des écrans d'affichage à LED, tels que le réglage des niveaux de gris, la correction des couleurs, le contrôle intelligent, etc.

Exemple : Certaines puces de pilote d'écran d'affichage LED haut de gamme disposent d'une fonction de réglage des niveaux de gris, qui permet un contrôle précis de la luminosité des perles de lampe LED, améliorant ainsi l'effet d'affichage.

Lors de la sélection d'un circuit intégré pour un écran d'affichage à LED, il est nécessaire de prendre en compte de manière exhaustive les scénarios d'application et les besoins spécifiques afin de garantir la stabilité et les performances de l'écran d'affichage. Dans le même temps, avec le développement continu de la technologie d'affichage à LED, de nouveaux produits et technologies de circuits intégrés continueront d'émerger, offrant davantage de possibilités pour l'application des écrans d'affichage à LED.

3. L'impact de la technologie IC sur les performances des écrans d'affichage LED

En tant que composant principal des écrans d'affichage à LED, la technologie des circuits intégrés a un impact vital sur les performances des écrans d'affichage. Voici quelques aspects clés de l'impact de la technologie des circuits intégrés sur les performances des écrans d'affichage à LED :

- Effet d'affichage :

Les circuits intégrés hautes performances peuvent fournir des taux de rafraîchissement plus élevés. Le taux de rafraîchissement fait référence au nombre de fois que l'écran d'affichage LED met à jour l'image par seconde. Un taux de rafraîchissement élevé peut assurer la fluidité et la continuité de l'image, en particulier lors de la lecture de vidéos dynamiques ou de l'affichage de scènes de mouvement à grande vitesse ; il peut éviter les déchirures ou le flou de l'image, rendant l'image plus claire et plus réaliste.

Les circuits intégrés hautes performances prennent également en charge des niveaux de gris plus élevés. Les niveaux de gris font référence aux niveaux de couleur et à la plage de variation de luminosité que les écrans d'affichage à LED peuvent afficher. Des niveaux de gris plus élevés peuvent présenter des couleurs plus délicates et plus riches et des changements de lumière et d'obscurité, rendant l'image plus vive et plus réaliste.

- Consommation d'énergie et vie :

La conception optimisée des circuits intégrés peut réduire la consommation d'énergie des écrans d'affichage à LED. En adoptant une technologie avancée de gestion de l'énergie et des algorithmes d'économie d'énergie, les circuits intégrés peuvent contrôler avec précision le courant et la tension des perles de lampe LED, éviter le gaspillage d'énergie inutile et ainsi réduire la consommation d'énergie globale de l'écran d'affichage.

Cela permet non seulement de réduire les coûts d’exploitation, mais également de réduire la consommation d’énergie et la pollution de l’environnement.

La conception optimisée des circuits intégrés peut également prolonger la durée de vie des LED. En contrôlant avec précision l'état de fonctionnement des perles de lampe LED, les circuits intégrés peuvent réduire les facteurs de dommages tels que la surchauffe et la surtension des LED, réduire le taux de défaillance des LED et ainsi prolonger la durée de vie de l'écran.

De plus, IC peut également réaliser la fonction de détection et de remplacement automatique des billes de lampe LED, améliorant encore la fiabilité et la stabilité de l'affichage.

- Fiabilité:

Les circuits intégrés de haute qualité ont des capacités anti-interférences plus fortes. Dans un environnement électromagnétique complexe, les circuits intégrés de haute qualité peuvent résister à l'influence de divers signaux d'interférence et assurer le fonctionnement stable de l'écran.

Cela permet d'éviter le scintillement, l'écran noir et d'autres phénomènes de défaillance sur l'écran et améliore la fiabilité et la stabilité de l'écran.

Les circuits intégrés de haute qualité présentent également une stabilité et une fiabilité supérieures. En adoptant des processus et des matériaux avancés, les circuits intégrés peuvent maintenir des performances stables dans des environnements difficiles tels que des températures élevées, une humidité élevée et des vibrations, garantissant ainsi que l'écran peut fonctionner normalement dans divers environnements complexes.

De plus, les circuits intégrés de haute qualité présentent également des taux de défaillance plus faibles et une durée de vie plus longue, améliorant encore la fiabilité et la stabilité de l'affichage.

4. Tendances futures du développement

Dans le domaine des écrans LED, la technologie des circuits intégrés est la force motrice principale et sa tendance de développement future mènera l'ensemble du secteur vers des performances supérieures et un développement plus écologique et plus intelligent. Voici quelques-unes des principales tendances de développement :

- Intelligence et intégration :

Avec l'intégration continue de technologies telles que l'Internet des objets, le big data et l'intelligence artificielle, les écrans LED deviendront de plus en plus intelligents. La technologie IC atteindra un niveau de contrôle intelligent plus élevé, comme le réglage adaptatif de la luminosité, la recommandation de contenu intelligent, la télécommande, etc.

Afin que l'écran d'affichage puisse ajuster automatiquement les paramètres d'affichage en fonction de l'environnement et des scénarios d'utilisation et offrir une expérience utilisateur plus intelligente et plus pratique.

Parallèlement, l'intégration est également une tendance importante pour le développement futur. En intégrant plusieurs fonctions dans une seule puce IC, la structure du système peut être simplifiée et la fiabilité et la stabilité du système peuvent être améliorées.

Par exemple, l’intégration de fonctions telles que la conduite, le contrôle et la gestion de l’alimentation dans une seule puce peut réduire considérablement la complexité et le coût du système.

- Économie d'énergie verte :

Avec l'attention croissante portée à la protection de l'environnement et aux économies d'énergie à l'échelle mondiale, les écrans LED évolueront dans une direction plus verte et plus économe en énergie. La technologie des circuits intégrés jouera un rôle clé dans ce processus, permettant une consommation d'énergie plus faible et une durée de vie plus longue en optimisant les algorithmes, en réduisant la consommation d'énergie et en améliorant l'efficacité de l'utilisation de l'énergie.

Par exemple, en utilisant une technologie avancée de gestion de l'énergie et des algorithmes d'économie d'énergie, IC peut contrôler avec précision le courant et la tension des perles de lampe LED pour réduire le gaspillage d'énergie inutile.

Dans le même temps, la fonction intelligente d'économie d'énergie peut également ajuster automatiquement la luminosité et la couleur de l'écran en fonction de l'environnement et des scénarios d'utilisation, réduisant ainsi encore la consommation d'énergie.

- Personnalisation et personnalisation :

Avec la segmentation continue du marché et la diversification des besoins des consommateurs, le marché des écrans LED accordera une plus grande attention aux besoins de personnalisation et de personnalisation. La technologie IC fournira un soutien solide pour répondre à cette demande.

Grâce à une conception de circuit intégré configurable et à un contrôle logiciel flexible, les écrans LED peuvent être personnalisés en fonction de différents scénarios d'application et des besoins des utilisateurs. Par exemple, il peut être personnalisé en fonction de différentes tailles d'écran, résolutions, luminosité, couleurs et autres paramètres pour répondre aux besoins d'affichage de différentes occasions.

Dans le même temps, la technologie IC peut prendre en charge une variété d'interfaces de données et de protocoles de contrôle, ce qui permet aux utilisateurs de connecter et de contrôler facilement divers périphériques externes.

Conclusion

Grâce à l'analyse ci-dessus, il n'est pas difficile de voir que les circuits intégrés jouent un rôle essentiel dans les écrans LED. Ils constituent non seulement la base du fonctionnement normal des écrans LED, mais également la clé pour améliorer les performances des écrans et réaliser diverses fonctions avancées. Avec l'avancement continu de la technologie et l'évolution de la demande du marché, l'application des circuits intégrés dans le domaine des écrans LED sera plus étendue et plus approfondie à l'avenir.

Enfin, si vous souhaitez en savoir plus sur les écrans LED, veuillez nous contacter.

Une réponse

Moi