Introducción

Have you discovered it? Although pantallas de visualización LED are made up of boxes spliced together to form a large screen, there is no gap when it is displayed, as if it is a complete screen without splicing.

Why does this happen? Why can LED display screens be seamless after splicing? This article will take these two questions to study LED display screens in depth.

1. A brief overview of LED display screen splicing technology

LED display screen splicing technology is actually splicing together many small LED display screens to form an ultra-large, ultra-high-definition large screen. Imagine, just like playing a jigsaw puzzle, putting small screens together to form a cool large screen!

In short, you have several small LED display screens and want to turn them into a large one. How to do it?

It is to use some high-tech means, such as precision machining, circuit connection, and software control, to seamlessly or almost seamlessly splice these small screens together. In this way, you get an ultra-large, ultra-high-definition large screen!

In addition, LED display screen splicing technology can make your LED display screen layout very flexible. This is actually due to its seamless splicing technology!

Through precise machining and installation technology, as well as professional splicing tools and control systems, the display signals of multiple LED splicing screens can be synchronously processed to ensure consistent display effects between each display screen.

Moreover, there are a variety of networking methods to choose from! For example, straight, curved, L-shaped, T-shaped, etc., to meet your different display needs and occasions!

2. What is the principle of achieving seamless LED display screens after splicing?

Do you know? The reason why LED display screens can achieve almost seamless effects after splicing is that there are a lot of high technologies behind them! Now, let’s uncover this mystery and see what the principle of achieving seamless LED display screens after splicing is.

1). Precise module design:

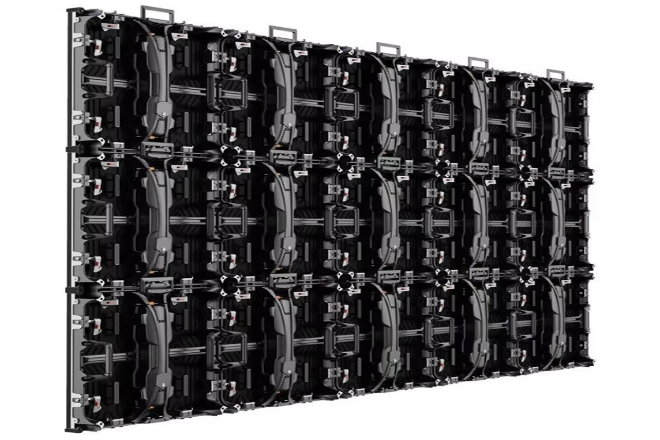

First of all, LED display screens are spliced together by small modules. The design of these modules is very precise, just like a puzzle, each piece must be tightly put together.

1.1). The arrangement of lamp beads is particular:

The LED lamp beads on each module are arranged according to specific spacing and arrangement methods. This design ensures that the spacing between the lamp beads is consistent when splicing and that there will be no obvious gaps or misalignments.

1.2). The layout of the circuit board should be reasonable:

The circuit board is the “brain” of the LED display, responsible for transmitting signals and controlling the on and off of the lamp beads. Therefore, the layout of the circuit board is very important.

A reasonable layout can ensure the stable transmission of signals, reduce interference, and make the display more stable and reliable.

1.3). Precise docking mechanism to help:

The modules also use precise docking mechanisms such as slots and positioning pins. These mechanisms are like the card slots of a puzzle, which can ensure that the modules can be accurately docked together when splicing to form a seamless effect.

2). High-precision manufacturing process:

The process of manufacturing LED display modules is also very particular, and high-precision manufacturing processes are required to ensure the consistency and quality of each module.

2.1). Strict control of size and shape:

During the manufacturing process, the size and shape of the module will be strictly controlled. Through high-precision machining and testing methods, ensure that the size and shape of each module are consistent so that there will be no gaps when splicing.

2.2). Surface treatment technology to help:

The surface of the module will also be flattened and anti-oxidation treated. Flattening can eliminate the tiny bumps on the module surface and improve the fit between modules, while anti-oxidation treatment can prevent poor contact or surface damage caused by oxidation during use.

2.3). Advanced splicing technology:

Finally, it is advanced splicing technology! These technologies are the key to achieving seamless splicing.

3.1). Seamless splicing technology shows its prowess:

Among them, micro-pitch splicing technology is a very advanced technology. It reduces the spacing between lamp beads to achieve higher pixel density and more delicate display effects.

At the same time, micro-pitch splicing can also effectively reduce the splicing gap, making the display look more complete and coherent.

3.2). Adjustment mechanism to help fine-tune:

During the splicing process, adjustment mechanisms such as fine-tuning screws and elastic connectors are also needed. Fine-tuning screws can accurately adjust the position and angle of the module to ensure the flatness after splicing.

While elastic connectors can absorb small differences and stresses between modules to improve the stability and flatness of splicing.

In general, the principle of achieving a seamless LED display screen after splicing is a very complex and delicate process. It involves many aspects, such as precise module design, high-precision manufacturing process, and advanced splicing technology.

It is the comprehensive application of these technologies that allows us to see such a shocking and perfect LED display screen effect!

3. Simple analysis of the technical advantages of a seamless LED display screen after splicing

1). Good visual effect:

Imagine that you are standing in front of a huge LED display screen, and the picture on the screen is smooth and coherent, without a single gap interrupting your sight. This is the visual feast brought by a seamless LED display screen after splicing!

Due to the disappearance of the splicing gap, the entire large-screen display is more unified. Whether it is playing video, pictures, or text, it can give you an immersive feeling, greatly improving the viewing experience.

2). High display quality:

Did you know? Gaps are the “big enemy” of LED display screens. They interfere with the propagation of light and affect the accuracy of color, thereby greatly reducing the display effect. However, seamless splicing technology perfectly solves this problem!

Without the interference of gaps, LED display screens can restore colors more accurately, and the displayed content is clearer and more delicate. Whether watching high-definition movies or appreciating art paintings, you can feel unprecedented visual shock.

3). Easy installation and maintenance:

Let’s talk about installation and maintenance. Did you know? The modular design of the LED display is very clever. Each module is independent and can be installed, disassembled, and maintained separately.

This means that if there is a problem with a module, you don’t need to replace the entire display. Just replace the problematic module. This modular design not only improves the efficiency of installation and maintenance but also greatly reduces the cost of use.

In general, the technical advantage of seamless LED display after splicing is really obvious. It not only makes the large-screen display more coherent and unified, but it also improves the viewing experience.

It also ensures the clarity and accuracy of the displayed content, and it also makes installation and maintenance more convenient and efficient. These technical advantages have jointly achieved the wide application and popularity of LED displays in various fields.

4. Application scenarios of seamless LED display after splicing

The technology of seamless LED display after splicing is widely used in many fields due to its excellent display effect and flexibility. Next, let’s take a look at its typical application scenarios.

1). Control room and monitoring center

In the control room and monitoring center, staff needs to monitor and analyze a large amount of data in real-time. This requires that the large-screen display must be high-resolution and interference-free to ensure the accuracy and readability of the data.

The technology of seamless splicing of LED display screens just meets this demand. It provides a continuous and unified display screen, allowing staff to see every detail more clearly and make more accurate judgments.

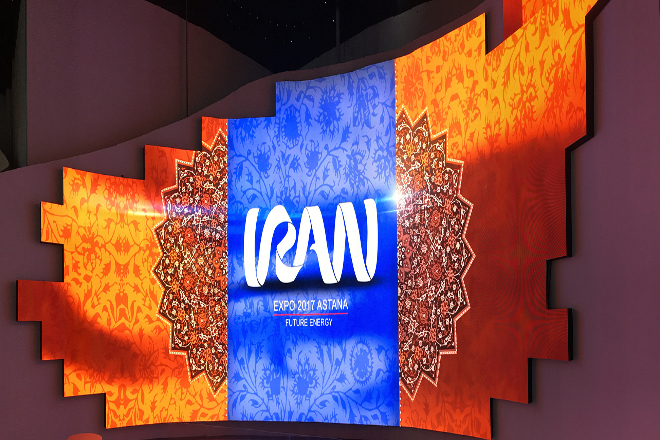

2). Escenario performances and event sites

For stage performances and event sites, a large-screen display is an important element to enhance the atmosphere of the scene. The seamless technology of LED display screens after splicing makes the large-screen display more coherent and shocking.

Whether it is playing videos, pictures, or animations, it can bring an immersive visual experience to the audience. This technology not only improves the effect of the performance but also makes the event site more attractive.

3). Commercial display and advertising

In the field of commercial display and advertising, large-screen display is an effective means to attract customers’ attention. The seamless technology of LED display screens after splicing allows products and advertisements to be displayed in front of customers more vividly and vividly.

This technology not only improves the display effect but also enhances customers’ willingness to buy and brand image.

5. Challenges and solutions for seamless LED display screens after splicing

1). Desafíos técnicos

- Differences in thermal expansion coefficients between modules:

Since LED display screen modules are made of different materials, their thermal expansion coefficients may differ. When the temperature changes, this difference may cause gaps between modules.

- Loosening after long-term use:

Over time, LED display screen modules may loosen due to factors such as vibration and temperature changes, thus affecting the display effect.

1.1) Solución:

- Use high-quality materials:

Select high-quality materials with similar thermal expansion coefficients and stable performance to manufacture LED display screen modules to reduce the gap problem caused by material differences.

- Optimize structural design:

By optimizing the structural design, such as using a tighter splicing method and adding fixing points, the stability and durability of the module can be enhanced.

- Strengthen maintenance:

Regularly maintain and service the LED display screen, such as checking the connection between modules and tightening screws, to ensure the long-term stable operation of the display screen.

Conclusión

Through the explanation in this article, we have a detailed understanding of the realization principle and technical advantages of seamless LED display screens after splicing.

This feature not only improves the display effect but also makes LED display screens widely used in various fields, such as control rooms, stage performances, and commercial displays.

Finalmente, si quieres saber más sobre las pantallas LED, Por favor póngase en contacto con nosotros.