Introducción

What kind of lamp beads should be used for pantallas LED de paso pequeño? I believe many people have thought about this question.

However, most of the small-pitch LED displays you see on the market now use GOB lamp beads.

So, why does this happen? Let’s take a look at this article with questions!

1. What processes are used for the lamp beads of small-pitch LED displays?

The lamp beads of small-pitch LED displays mainly use a variety of packaging processes to meet different performance requirements and application scenarios. The following are the main processes for small-pitch LED display lamp beads:

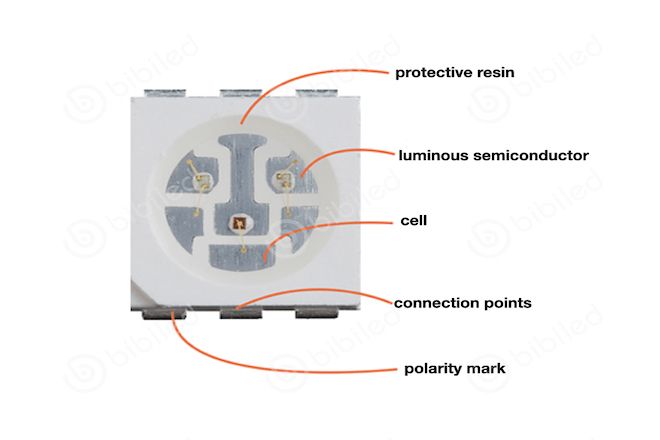

1). SMD (Surface Mounted Devices) packaging

SMD, or Surface Mount Device, is a packaging technology widely used in modern electronics manufacturing. In the field of LED displays, SMD packaging technology involves precisely fixing tiny LED bare chips on a special bracket (or substrate).

These brackets usually have positive and negative pins or pads for subsequent electrical connections.

Then, through a precise metal wire bonding process, the positive and negative electrodes of the LED chip are connected to the corresponding pins on the bracket to achieve electrical conduction.

In order to protect the fragile LED chips and metal wire connections, the entire structure will be encapsulated with a layer of epoxy resin material to form a strong and waterproof SMD LED lamp bead.

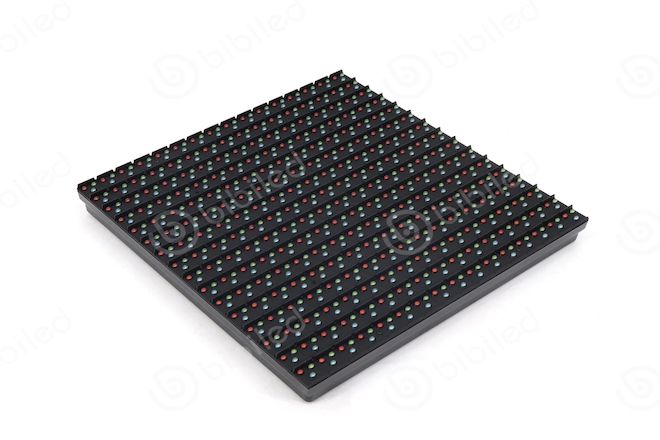

Finally, these lamp beads are firmly welded to the PCB (Printed Circuit Board) through an automated reflow soldering process to form a display unit module, which is then assembled into a complete LED display.

2). MAZORCA (Chip On Board) packaging

COB packaging technology is an advanced method of directly packaging LED chips on PCB boards. Unlike SMD, COB technology eliminates the need for separate LED lamp bead packaging steps and instead adheres multiple LED chips directly to the surface of the PCB.

This is usually accomplished with conductive or non-conductive glues that not only provide adhesion but may also be conductive to simplify electrical connections. Subsequently, the LED chip is directly connected to the circuit on the PCB through wire bonding technology or more advanced flip-chip technology to form an electrical path.

This packaging method significantly improves the integration of LED chips, reduces the use of packaging materials, and may improve overall optical performance and thermal management efficiency.

3). GOB (Glue on Board) packaging

GOB packaging technology is an enhanced surface protection technology for small-pitch LED displays. It is not a new LED packaging method but an improvement on the traditional SMD packaging module.

In GOB technology, the surface of LED lamp bead modules that have been packaged through SMD or other methods will be covered with a layer of transparent colloidal material.

This layer of colloid not only provides additional mechanical strength to prevent the module from being damaged during transportation, installation, and use, but also enhances the module’s moisture-proof, dustproof, and scratch-proof capabilities.

In addition, GOB technology may further improve the visual effect of the display screen by optimizing the refractive index and light transmittance of the colloidal material.

4). ADEREZO package

The DIP packaging structure is relatively simple. The LED chip is packaged between two pins and usually exists in the form of a single LED lamp bead.

This packaging method allows each LED lamp bead to work independently, making it easy to repair and replace. The DIP LED display has high brightness, is suitable for use in outdoor environments, and can maintain good display effects under strong light.

At the same time, DIP-encapsulated LED lamp beads have good waterproof, dustproof, and UV-proof properties and can adapt to various harsh environments.

2. What are the advantages of GOB compared to other lamp bead processes?

Compared with other lamp bead processes, the advantages of GOB (Glue on Board) packaging technology are mainly reflected in the following aspects:

1). Enhanced protection

- Alto nivel de protección:

The GOB process significantly improves the protection level of the display by encapsulating a layer of transparent colloid on the surface of traditional SMD small-pitch modules.

This layer of colloid not only provides additional mechanical strength, but also enhances the display’s ability to be moisture-proof, waterproof, dustproof, anti-collision, and anti-corrosion, allowing it to adapt to harsher usage environments.

- All-round protection:

The GOB process realizes comprehensive protection of the display screen, effectively preventing failures and damage caused by external environmental factors (such as moisture, dust, impact, etc.) and extending the service life of the display screen.

2). Improve display effect

- More uniform light emission:

The GOB process optimizes the refractive index and light transmittance of the colloidal material, making the display screen more uniform in light emission, reducing the appearance of light spots and dark areas, and improving the overall visual effect.

- Improved viewing angle:

Due to the existence of the colloid layer, the GOB process can also improve the viewing angle of the display to a certain extent, allowing viewers to obtain a clear and consistent viewing experience at different angles.

3). Adapt to a wider range of application scenarios

- Breakthrough in small-pitch display screens:

The emergence of GOB technology has broken the bottleneck of small-pitch LED displays in terms of protective performance, allowing small-pitch displays to be widely used in scenes that require higher protection levels (such as publicidad exterior, Deportes venues, etc. ).

- Diversified display needs:

With the continuous development of display technology, users have put forward higher requirements for the display effect, protective performance, service life and other aspects of the display screen. The GOB process meets these diverse needs with its unique advantages and injects new vitality into the development of the display market.

3. The benefits of the GOB process for small-pitch LED display lamp beads

The lamp beads of the small-pitch LED display adopt the GOB (Glue on Board) process, which brings many significant benefits.

1). Reduce the occurrence of lamp beads falling:

In the production of traditional LED displays, lamp beads may become loose or even fall due to vibration, temperature changes, or improper installation. This not only affects the display effect but may also cause damage to the entire display.

The GOB (Glue on Board) process applies a layer of stable, transparent colloid to the outer layer of the lamp bead to firmly lock the lamp bead with the substrate, significantly reducing the risk of the lamp bead falling due to external factors and improving the efficiency of the lamp bead. The overall robustness and security of the display.

2). The protective ability of lamp beads is enhanced:

The GOB process is not only a simple packaging method but also a comprehensive protection of the lamp beads.

This process achieves eight major protective properties: waterproof, moisture-proof, bump-proof, dustproof, anti-corrosion, anti-blue light, anti-salt spray, and anti-static. These characteristics are like putting on a layer of indestructible armor for the lamp beads.

Whether facing harsh outdoor environments or complex indoor application scenarios, they can effectively extend the service life of the display and greatly improve its stability and reliability.

At the same time, these protective features also reduce lamp failure and damage caused by external environmental factors, reducing subsequent maintenance costs.

3). Improve the overall brightness and clarity of the picture:

During the packaging process of the GOB process, through careful selection and processing of colloid materials, light can be better distributed and diffused when passing through the colloid layer.

In this way, when the display plays content, the overall brightness of the picture is more uniform, the colors are fuller, and the details are displayed more clearly.

Whether you are watching high-definition videos or appreciating exquisite pictures, you can get a more realistic and vivid visual experience.

4). Expanded ángulo de visión:

Traditional LED displays often have certain limitations in viewing angles. Especially when the viewing angle deviates greatly, the picture will suffer from color distortion or brightness decrease.

The GOB process optimizes the refraction and scattering properties of the colloid layer, allowing light to maintain uniform distribution over a wider angle range. This means viewers can view the display from more angles without worrying about compromised picture quality.

This improvement undoubtedly brings a more free and comfortable viewing experience to the audience.

5). Improve contrast:

The GOB process also significantly improves the contrast of the display screen by realizing the transition from point light source to area light source. Traditional point light source LEDs are prone to producing light spots and dark shadows when emitting light, which affects the fineness and layering of the picture.

The GOB process converges the light from multiple LED lamp beads into a uniform surface light source, reducing the generation of light spots and shadows. At the same time, the matte-effect colloid layer further reduces glare and glare, making the picture softer and more comfortable.

This high-contrast display helps viewers more clearly identify details and color changes in the picture.

6). Reduce the dead light rate:

Deadlight is one of the common faults of LED displays. It is often caused by quality problems of the lamp beads themselves or the harsh influence of the external environment.

The GOB process effectively reduces the occurrence of dead lamps by enhancing the stability and reliability of lamp beads. On the one hand, the colloid layer provides a good protective barrier for the lamp beads and reduces the erosion of the lamp beads by the external environment.

On the other hand, the GOB process also strictly screens and tests the lamp beads during the packaging process to ensure the stability of their quality. And reliability. This double guarantee makes the GOB process excellent in reducing the dead light rate.

7). Diverse display requirements:

With the continuous changes in market demand, users have put forward more diverse requirements for the display effect, protective performance, service life, and other aspects of the display screen. The GOB process meets these diverse needs with its unique advantages.

Whether it is an outdoor advertising screen that requires high protective performance, a sports stadium display that requires high definition and wide viewing angles, or a stage rental display that requires flexible and convenient installation, GOB technology can provide tailor-made solutions.

This diverse application scenario allows the GOB process to occupy an important position in the display market and injects new vitality into the development of the market.

Conclusión

In summary, the use of GOB technology for small-pitch LED display lamp beads is undoubtedly an important measure to improve the overall performance and market competitiveness of the display.

It not only solves the shortcomings of traditional display screens in terms of protection, display effects, and maintenance costs but also opens up a broader space for the future development of display screens.

As GOB technology continues to mature and become more popular, we have reason to believe that small-pitch LED displays will show their unique charm in more fields and bring more colors and surprises to our lives.

Finalmente, si quieres conocer más información sobre las pantallas LED, Por favor póngase en contacto con nosotros.