Introducción

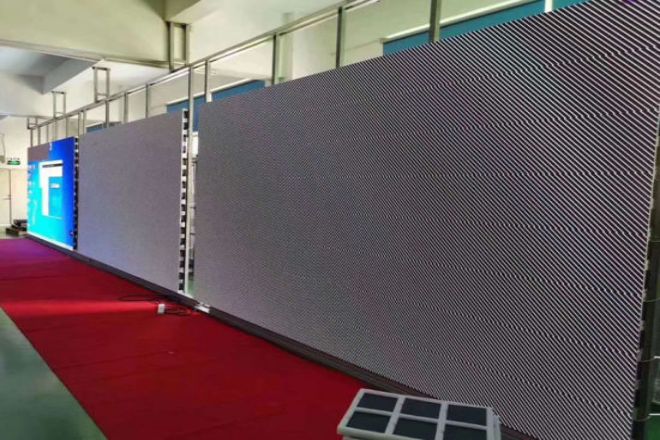

The color performance and brightness uniformity of the Pantalla LED directly affect the audience’s visual experience. Point-by-point correction technology has become a key link in the production of LED display screens to achieve high-quality display effects.

This article will take you through point-by-point correction.

1. What is point-by-point correction?

Point-by-point correction, also known as pixel correction or brightness correction, is a process of adjusting brightness for a specific area or individual pixel of an LED display.

By finely adjusting the brightness of each LED bead, point-by-point correction can eliminate differences in the brightness of the display and improve the consistency of the overall display effect.

2. Why does the LED display need to be calibrated point by point?

Point-by-point correction of LED displays is an important technology, mainly used to improve the brightness uniformity and color fidelity of the display. Whether before leaving the factory or after a period of use, point-by-point correction technology can significantly improve the uniformity of the display and significantly improve image quality.

1). Point-by-point correction before leaving the factory: quality improvement and competitiveness enhancement

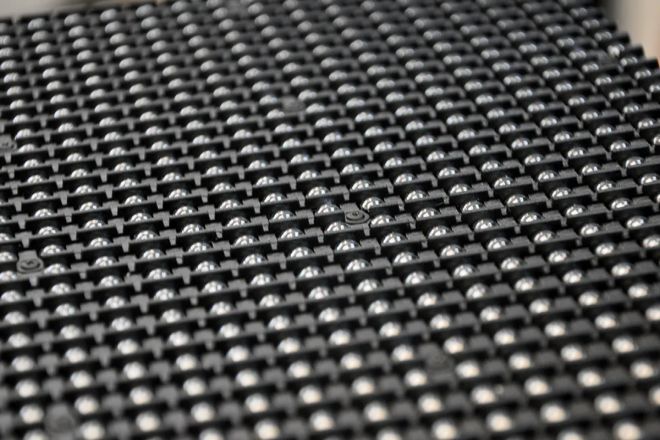

In the manufacturing process of LED displays, due to differences in production processes and materials, there may be subtle differences in the luminous efficiency of different LED lamp beads.

These differences will cause problems such as uneven brightness and color shift in the display, thus affecting the overall display effect. The use of point-by-point correction technology can effectively eliminate these differences and improve product uniformity and color fidelity.

Through point-by-point correction, manufacturers can ensure that each display has consistent brightness and color performance, thereby improving the overall quality of the product.

This can not only meet customers’ demand for high-quality display effects but also enhance the competitiveness of products and expand business opportunities.

2). Point-by-point correction during use: extending the life of pleasing eyes and creating business value

During the long-term use of LED displays, the brightness and color performance will change due to aging, environmental factors, etc. In order to maintain the best display effect, regular point-by-point correction becomes particularly important.

This correction not only helps eliminate differences in brightness and chromaticity but also keeps the color and brightness of the display at its best by adjusting parameters.

Point-by-point correction can extend the “eye-pleasing life” of LED displays and create more commercial value for users. With regular maintenance and calibration, displays can remain in good working order and reduce replacement costs due to brightness degradation or color shifts.

This not only reduces operating costs but also provides users with more stable and high-quality display effects and enhances user loyalty.

3. Point-by-point correction method

Point-by-point calibration procedures are divided into 2 types: hardware calibration and software calibration.

1). Hardware correction:

By installing brightness adjustment components on the LED display module, such as electrically adjustable resistors or integrated ICs, the brightness of each LED lamp bead can be adjusted. Hardware correction is usually done during production, but the scope of adjustment is limited.

2). Software correction:

Use dedicated control software and hardware devices to perform brightness and color correction on the display. Software correction is flexible and repeatable, adapting to a variety of display modes and scenarios.

3). The steps are as follows:

Collect data: Use high-precision measuring equipment to measure the brightness of each pixel of the LED display to obtain the actual brightness value of each pixel. The measurement range can be the entire display, an area, or a single pixel.

Analyze data: According to the measured brightness value, analyze the distribution of brightness and find out the reasons for uneven brightness and color. At the same time, determine the pixels that need to be adjusted and the corresponding adjustment parameters based on actual needs and standard range.

Develop a correction plan: Based on the analysis results, formulate a corresponding correction plan. The plan should include the parameters to be adjusted, the methods and steps for adjustment, etc.

Implement correction: According to the formulated correction plan, adjust the brightness of the corresponding pixels through control software or hardware equipment. The parameters to be adjusted include brightness value, chroma value, etc. The adjustment method can be software control or hardware adjustment.

Verify the effect: After completing the brightness adjustment, verify the effect of the display to check the consistency of brightness and color, the authenticity of the display effect, etc. If necessary, you can fine-tune the adjustment parameters to achieve the best display effect.

Data storage and backup: Store the corrected data in the control system and back it up regularly so that correction and data recovery can be performed again when needed.

4. Noteworthy places

Through point-by-point correction of the LED display, the consistency and accuracy of the display effect can be improved.

It should be noted that the calibration process requires the use of high-precision measuring equipment, the development of a scientific calibration plan, and the correct implementation of adjustment operations.

At the same time, in order to ensure the stability and durability of the correction effect, regular maintenance and review are required.

Conclusión

The above is the entire content of this article. We know that mainstream LED display correction and on-site correction are two effective technical means that can help extend the service life of LED displays.

If you want to know more knowledge, Por favor póngase en contacto con nosotros!