Introducción

Durante el uso de pantallas LED, color aberration problems often occur, which not only affects the display effect but also reduces the user experience. Therefore, how to solve the color difference problem of LED display screens has become an urgent technical problem that needs to be solved.

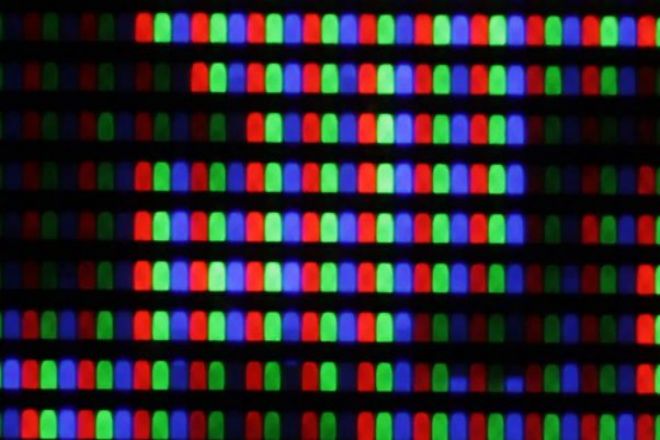

The main problem of chromatic aberration is that when the LED display displays the same color, there are differences in brightness, hue, and saturation in different areas, resulting in uneven pictures and color distortion.

This not only affects the accurate communication of information but may also pose a potential threat to the user’s visual health. Therefore, solving the color difference problem of LED displays is of great significance for improving display quality and protecting user rights.

To solve this problem, we need to approach it from many aspects.

1. Why does the LED display have a color difference?

There are many reasons for color differences in LED displays, mainly including the following aspects:

Differences in LED chip quality: LED displays are composed of a large number of LED lamp beads, and the performance and quality of each lamp bead may vary. This difference may cause differences in brightness, hue, and saturation in different areas of the display when displaying the same color, resulting in color differences.

Instability of the driving current and control signal: If the driving current and control signal of the LED display screen are unstable, the luminous intensity and color of the LED lamp beads will change, resulting in chromatic aberration. This may be caused by an unstable power supply, control system failure, or data transmission errors.

Influence of ambient temperature and humidity: The working environment of the LED display also has a great impact on its display effect. If the display screen is operated in a high temperature or high humidity environment for a long time, the performance of the LED lamp beads may be reduced, resulting in color differences.

Display aging and improper maintenance: As the use time increases, LED display screens may experience aging phenomena, such as reduced brightness, color deviation, etc. In addition, if the display screen has not been maintained or cleaned for a long time, it may also cause color difference problems.

2. What does the color difference of LED display look like?

The main manifestation of the color difference of LED display is that when displaying the same color, there are differences in brightness, hue, and saturation between different areas or pixels, causing the overall picture to appear uneven or color distorted. Specifically, color differences may appear in the following forms:

Brightness difference: On an LED display, the brightness of some areas is significantly higher or lower than other areas, resulting in uneven light and darkness in the picture. This difference may be caused by inconsistent brightness of the LED lamp beads or unstable driving current.

Hue deviation: When the display screen displays a certain color, the color in some areas deviates from the expected color, appearing reddish, greenish, blueish, etc. This may be caused by differences in the hue of the LED chip itself or inaccurate color processing by the control system.

Inconsistent saturation: Some colors in the image may appear too bright or too dull, with noticeable differences in color saturation from other areas. This may be caused by different luminous efficiency of LED lamp beads or inaccurate color calibration.

Mosaic and blooming phenomenon: When the color difference problem is serious, an obvious mosaic effect or blooming phenomenon may appear on the screen; that is, pixel blocks of different colors or brightness are intertwined, resulting in a serious decline in picture quality.

3. Solutions to the color difference problem of LED displays

In order to maintain the LED display and avoid the occurrence of color differences, you can start with the following aspects:

- Choose high-quality LED chips

Purchasing high-quality LED chips is the first step to preventing color difference problems. High-quality LED chips not only have high luminous efficiency but also good color reproduction, which can present a more realistic picture effect.

Therefore, when choosing LED chips, you should give priority to products from well-known brands. These brands usually have strict quality control processes and advanced production processes to ensure the consistency and stability of the chips.

In addition, you also need to pay attention to key indicators such as hue, brightness, and lifespan of the LED chip. Chips with small hue deviation, uniform brightness, and long life can maintain stable color performance during long-term use and reduce the occurrence of chromatic aberration problems.

- Optimized drive and control technology

Driving and control technology has an important impact on the color performance of LED displays. In order to ensure a stable supply of current, you should use advanced constant current drive technology to effectively avoid color distortion problems caused by current fluctuations.

At the same time, we also need to optimize the signal transmission process, reduce signal interference and distortion, and ensure that the display screen can accurately receive and present the original color information.

In addition, with the continuous development of technology, new driving and control algorithms and technologies are constantly emerging. You can pay attention to the development of these new technologies and introduce and apply them according to actual needs to further improve the color accuracy and stability of LED displays.

- Environmental adaptability improvement

The working environment of LED displays is complex and changeable, and harsh environments such as high temperature and high humidity may have adverse effects on the color performance of the display.

Therefore, you need to make improvements based on these environmental factors to improve the environmental adaptability of the display.

Specifically, you can design a more efficient cooling system to ensure that the display maintains the appropriate temperature range during operation.

At the same time, you should also improve the waterproof and moisture-proof capabilities of the display and use waterproof sealing materials and reinforced protective designs to ensure that the display can work normally in humid environments.

- Regular maintenance and calibration

Regular maintenance and calibration are important means to maintain the color accuracy and stability of LED displays. You should establish a regular maintenance system to clean, inspect, and maintain the display screen regularly.

Cleaning the display surface can remove dust and dirt and maintain the clarity of the picture; checking the connection lines and replacing aging parts can ensure the normal operation of the display, and regular color calibration can ensure the color accuracy and consistency of the display.

When performing color calibration, you should use professional color calibration equipment and methods to adjust the color parameters of the display accurately. Through regular calibration, we can discover and solve potential color difference problems in time to maintain the best display effect of the display.

- Pay attention to the use and storage of the display screen.

In addition to the above measures, you also need to pay attention to how the display is used and stored. During use, avoid prolonged use under strong sunlight to reduce the impact of ultraviolet rays on the display.

At the same time, when storing, you should choose a dry, ventilated place away from direct sunlight to ensure that the display is stored in a good environment.

To sum up, by purchasing high-quality LED chips, optimizing drive and control technology, improving environmental adaptability, regular maintenance and calibration, and paying attention to the use and storage of the display, we can effectively maintain the LED display and avoid the occurrence of color differences.

These measures can not only extend the service life of the display but also improve the user’s visual experience and ensure that the display can present the best picture effect in various application scenarios.

4. How do we maintain and prevent color differences in LED displays?

Later maintenance of the LED display screen to prevent color differences can be carried out from the following aspects:

- Regular inspection and tightening:

Carry out regular inspections according to the display screen’s usage environment. For small indoor screens, the environment is relatively stable, and inspection once a month is sufficient; for semi-outdoor, outdoor, and large indoor and outdoor screens, due to the changeable environment, it is recommended to inspect once a week.

The inspection content includes checking whether the LED lamp beads of the display screen are working properly and checking whether the connecting lines and fasteners are loose.

Because the LED screen is a high-power-consuming device, after long-term use, the components may become loose due to the combination of cold and heat, so they need to be tightened regularly to ensure the consistency of the display effect.

- Limpieza periódica:

Dust will not only reduce the thermal conductivity and insulation performance of the display but also absorb moisture in the air and cause short circuits in humid weather.

In the long term, it may also cause mildew on PCB boards and electronic components, reducing the technical performance of the equipment. Error occurred. Therefore, it is very necessary to clean the display screen regularly, especially outdoor screens. Due to the harsh use environment and large amount of dust, frequent cleaning is required.

- Calibración de color:

Use professional equipment to regularly perform color calibration on the display to ensure color accuracy and consistency. Color calibration should take into account factors such as ambient brightness and viewing distance to ensure the comfort and authenticity of the display.

- Software adjustment:

By adjusting and correcting the software of the full-color LED display, the color distortion problem can be solved to a certain extent. When adjusting the software, the color should be accurately controlled according to actual needs to avoid color deviation.

- Control ambiental:

Maintain the stability of the display working environment and avoid direct sunlight and excessively humid environments to reduce the occurrence of color distortion. At the same time, do a good job of dissipating the heat of the display. Poor heat dissipation will cause color aberration problems in the LED display.

Conclusión

After in-depth analysis and discussion of the color difference problem of LED displays, we can clearly see that solving this problem requires comprehensive consideration of multiple aspects.

From purchasing high-quality LED chips to optimizing drive and control technology to improving environmental adaptability and strengthening regular maintenance and calibration, every link is crucial.

Si quieres saber más sobre las pantallas LED, Por favor póngase en contacto con nosotros.