Introduction

With the continuous development of electronic lighting technology and the continuous expansion of application fields, lamp beads are the core components of lighting equipment, and the selection and optimization of their processes are particularly important.

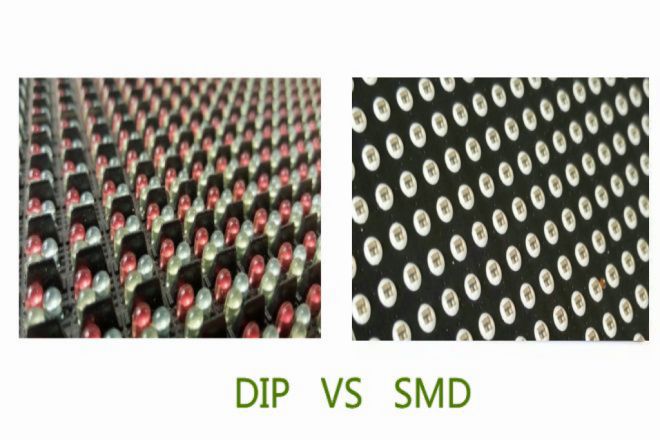

SMD (Surface Mount Device) lamp bead technology and DIP (Dual Inline Package) lamp bead technology are two mainstream packaging technologies currently on the market, each with unique advantages and limitations.

This article will provide an in-depth comparative analysis of these two processes, aiming to help you more comprehensively understand their performance characteristics and application scenarios and provide a reference for selection in the industry.

1. SMD lamp bead process analysis

1). SMD lamp bead process principle

- Production process

The manufacturing process of SMD lamp beads includes chip preparation, packaging, and testing. First, high-quality LED chips are prepared through precise manufacturing processes.

Advanced packaging technology is then used to package the chip in a small plastic shell to form an SMD lamp bead. Finally, the packaged lamp beads are rigorously tested to ensure that their performance is stable and reliable.

- Core principles of surface mount technology

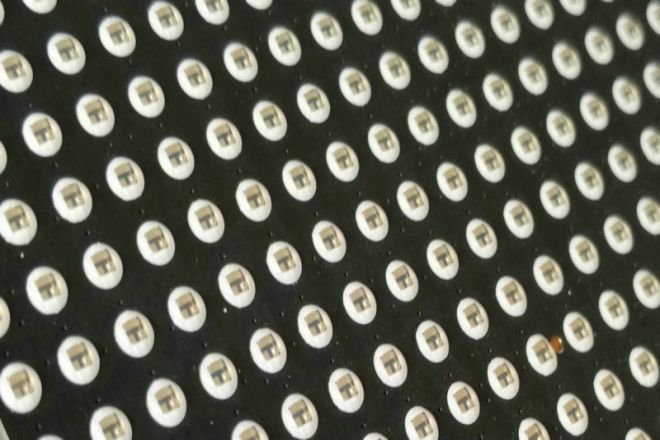

The core principle of SMD lamp bead surface mounting technology is to use a high-speed placement machine to accurately place the packaged lamp beads on the designated position of the circuit board.

This technology achieves fast and accurate connection between lamp beads and circuit boards through a precise positioning system and high-speed motion control.

During the mounting process, the pins of the lamp beads and the pads of the circuit board are connected through a high-temperature reflow soldering process to form electrical connections and mechanical fixation.

2). Advantages of SMD lamp bead technology

- Small size and lightweight

SMD lamp beads use surface mount technology and are packaged in a small plastic shell, so they are relatively small and light in weight. This allows SMD lamp beads to accommodate more LED chips in a limited space, improving the space utilization of the circuit board.

- High degree of automation and high production efficiency

The production process of SMD lamp beads is highly automated, and fast and accurate placement and welding are achieved through automated equipment such as high-speed placement machines. This greatly improves production efficiency and reduces production costs.

- Better heat dissipation performance

The packaging structure of SMD lamp beads is conducive to heat dissipation, which can effectively dissipate the heat generated by the LED chip and maintain the stable operation of the lamp beads. At the same time, due to the small size and light weight of SMD lamp beads, it is also helpful to reduce heat accumulation.

- High reliability and good earthquake resistance

The packaging structure of SMD lamp beads is compact and strong and can effectively resist external vibration and impact. At the same time, because the production process of SMD lamp beads is highly automated, the product quality is stable and reliable and has high reliability.

3). Disadvantages of the SMD lamp bead process

- High requirements for accuracy and flatness of circuit boards

Due to the small size and light weight of SMD lamp beads, the accuracy and flatness of the circuit board must be high. If the accuracy and flatness of the circuit board are not enough, it may easily lead to problems such as poor connection or short circuit between the pins of the lamp beads and the pads.

- Relatively difficult to repair and replace

Since the packaging structure of SMD lamp beads is compact and solid, once they fail or are damaged, it is relatively difficult to repair and replace them. Removal and replacement require specialized equipment and skills. This increases maintenance costs and time costs.

2. DIP lamp bead process analysis

1). DIP lamp bead process principle

- Production process

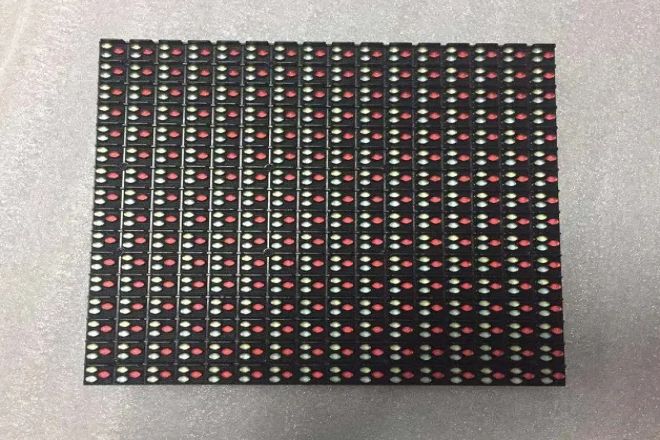

The production process of DIP lamp beads mainly includes chip preparation, packaging, and lead molding. First, high-quality LED chips are prepared through precise processes.

Subsequently, the LED chip is packaged in a special DIP packaging case. This step ensures the stability and reliability of the chip. Finally, the pins are fixed on the package shell through the molding process to complete the production of DIP lamp beads.

- Core principles of dual inline packaging technology

DIP lamp beads adopt dual inline packaging technology, and its core principle lies in the design of the pins. The pins of DIP lamp beads are arranged in two columns, and the pins are long, which allows them to be directly inserted into the corresponding holes of the circuit board and form an electrical connection with the circuit board through soldering. This packaging technology makes DIP lamp beads more flexible and convenient during installation.

2). Advantages of DIP lamp bead technology

- Long pins, convenient for manual welding and replacement

The long pin design of DIP lamp beads makes it easy to complete the circuit board installation process by manual soldering, even without automated equipment. At the same time, due to the long pin, when the lamp bead fails, it can be easily disassembled and replaced.

- The packaging structure is simple, and the cost is relatively low

The packaging structure of DIP lamp beads is relatively simple, which makes its production cost relatively low. In addition, due to the selection of packaging materials and the simplification of the packaging process, DIP lamp beads have certain advantages in cost control.

- High reliability, proven by the market over a long period of time

As a traditional packaging technology, DIP lamp beads have been market-verified for a long time. Its stable performance and reliable connection make it still competitive in many application scenarios.

3). Disadvantages of the DIP lamp bead process

- Large size is not conducive to high-density circuit board design

Due to the packaging structure and pin design of DIP lamp beads, their size is relatively large. This makes DIP lamp beads occupy a larger space in high-density circuit board designs, which is not conducive to achieving high integration of circuit boards.

- The degree of automation is relatively low, and the production efficiency is low

Compared with SMD lamp beads, DIP lamp beads have a relatively low degree of automation. In the production process, more reliance is placed on manual operations, which results in relatively low production efficiency.

- The heat dissipation performance is relatively poor, which may affect the life of the lamp beads.

The packaging structure and pin design of DIP lamp beads may affect their heat dissipation performance to a certain extent. When the lamp bead is running at high power, if the heat dissipation is poor, the temperature of the lamp bead may increase, thus affecting its life and stability.

3. Comparison between SMD lamp bead process and DIP lamp bead process

When comparing the SMD (Surface Mounted Devices) lamp bead process with the DIP (Dual Inline Package) lamp bead process, we can consider the volume and weight, production efficiency and cost, heat dissipation performance, and reliability. Conduct a detailed analysis of characteristics, application fields, and market demand.

1). Volume and weight:

- SMD lamp bead process:

The package is small, and the spacing between lamp beads is relatively small, so the overall volume and weight are lighter. This feature makes SMD lamp beads more flexible in circuit board design and application environments and can adapt to more compact design needs.

- DIP lamp bead process:

The package is larger, and the spacing between lamp beads is also larger, so the overall volume and weight are relatively heavier. This feature makes DIP lamp beads more widely used in some situations that do not require high space, but they may be limited in situations that require compact design.

2). Production efficiency and cost:

- SMD lamp bead technology:

It is easy to install and can be completed through surface mounting technology, so the production efficiency is high. At the same time, due to the compact packaging, a higher degree of automated production can be achieved, further reducing costs.

- DIP lamp bead process:

The installation is complicated and requires pin welding, etc., so the production efficiency is relatively low. In addition, the DIP package is larger, and the overall thickness of the display is thicker, which also increases production costs.

3). Thermal performance and reliability:

- SMD lamp bead process:

the spacing between lamp beads is small, due to the use of surface mounting technology, the contact area between the lamp beads and the circuit board is larger, and the heat dissipation performance is relatively good.

However, due to the smaller overall size and correspondingly smaller heat dissipation area, heat dissipation issues may be faced in high-power applications.

- DIP lamp bead process:

The heat dissipation performance is relatively poor because the DIP package is larger, and the spacing between lamp beads is also larger, resulting in a smaller heat dissipation area.

In addition, DIP packaging may also cause heat interference between lamp beads, further reducing heat dissipation performance. However, because its larger size can accommodate more heat-dissipation materials or structures, it may have better heat-dissipation performance in some applications.

4). Application areas and market needs:

- SMD lamp bead technology:

Due to its compact size and high production efficiency, SMD lamp bead technology has been widely used in consumer electronics, automotive electronics, communication equipment, and other fields.

Especially in occasions with strict space requirements and cost sensitivity, SMD lamp bead technology has greater market potential.

- DIP lamp bead process:

Although the DIP lamp bead process has shortcomings in some aspects, its high-temperature resistance and large viewing angles make it still have certain application requirements in outdoor displays, billboards, and other occasions.

In addition, in some situations where volume and weight are not high, the DIP lamp bead process can also be used as an economical and practical choice.

4. How do you choose between these two lamp bead technologies when purchasing?

When choosing between SMD (surface mount device) lamp bead technology or DIP (dual inline package) lamp bead technology, you need to consider the following key factors:

- Application scenarios:

Due to its small size and thin design, SMD lamp beads are suitable for use in electronic products with limited space and require compact design, such as consumer electronics, automotive electronics, communication equipment, etc.

Due to their large size, DIP lamp beads are usually suitable for occasions with low space requirements, such as outdoor displays, billboards, etc.

- Performance requirements:

SMD lamp beads have relatively good heat dissipation performance and are suitable for high-power density applications. However, due to its small spacing between lamp beads, it may affect the display effect in some cases.

The heat dissipation performance of DIP lamp beads is relatively poor, but its high-temperature resistance is good, and the distance between lamp beads is large, which can achieve a larger viewing angle and better display effect.

- Production efficiency and cost:

The SMD lamp bead process has high production efficiency and relatively low cost because automated production lines can be used for mass production.

The production efficiency of the DIP lamp bead process is relatively low, and the cost is high because it requires more manual operations, pin welding, and other steps.

- Reliability and longevity:

Due to its packaging method, SMD lamp beads may have a certain impact on the protection level and durability. It is necessary to pay attention to its moisture-proof, waterproof, dust-proof, and other properties.

DIP lamp beads may be relatively good in these aspects, but may be more susceptible to physical impact due to their larger size and weight.

- Maintenance and replacement:

SMD lamp beads are relatively easy to install and replace due to their surface mounting technology, but they may require special maintenance tools and techniques.

The installation and replacement of DIP lamp beads may require more manual operations but are usually more intuitive and easy to understand.

- Other considerations:

It is also necessary to consider the overall design of the product, cost budget, production cycle, and other factors, as well as the supply situation and price trends of various lamp bead processes on the market.

Conclusion

Through the comparative analysis of SMD lamp bead technology and DIP lamp bead technology, we can clearly see the differences between the two in terms of volume, weight, production efficiency, cost, heat dissipation performance, and reliability.

Each process has its unique application scenarios and market demands, and the correct selection and optimization of the process is crucial to improving the performance of lighting equipment, reducing costs, and meeting market demands.

Finally, if you want to know more about LED displays, please get in touch with us.