مقدمة

Users who often use شاشات عرض LED will find that when your LED display screen has been used for a long time, color difference problems often occur, which not only affects the display effect but may also have a negative impact on the brand image and user experience.

Why does the LED display screen have a color difference after a long time of use? Now, let’s talk about this issue in detail.

Analysis of the causes of color difference after long-term use of LED display

1). Aging and quality problems of LED lamp beads

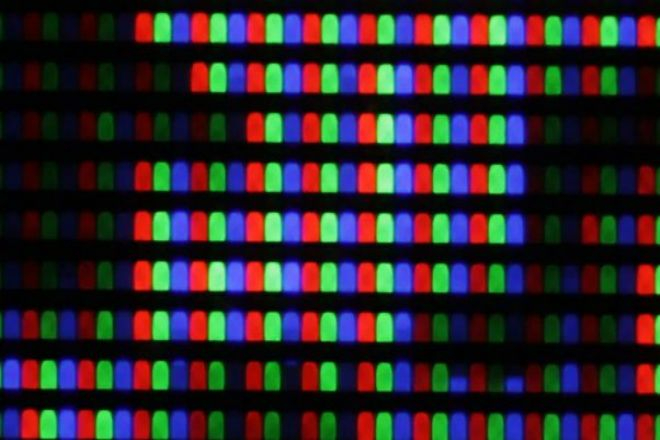

LED lamp beads are like small light bulbs on the display screen. They will get old after a long time of use. This kind of “aging” is aging. The brightness of the lamp beads will gradually dim, and the color may become less pure.

For example, the original bright red may become a little dark red or yellowish. Moreover, even the lamp beads of the same batch may have good or bad quality.

After a long time of use, these poor quality lamp beads are more likely to have problems, unstable light emission, and wrong color, so that color difference will appear on the display screen.

2). Production process and material problems

Making LED display screens is like making cakes. Both process and materials are very important.

If the process is not good, such as the glue that seals the lamp beads is problematic, or the position of the lamp beads is not accurate, and the color is not divided properly, it will cause the lamp beads to emit unstable light and different colors.

In addition, materials are also very important. Phosphor is like the frosting on the cake. If the frosting is of poor quality or unevenly applied, the cake will not look good.

Similarly, if the phosphor is of poor quality or unevenly applied, the color of the lamp beads will be different, and color differences will appear on the display.

3). مزود الطاقة system problem

LED display needs electricity to light up, just like mobile phones need to be charged. If the power supply system is unstable, just like the battery of the mobile phone fluctuates, the lamp beads on the display will be bright and dark, and the color may also change.

Moreover, the power supply will become old after being used for a long time, just like the battery will not last long after being used. When the power supply gets old, the power supply will be unstable, and the color difference on the display will be more obvious.

4). Control system and IC problem

The control system of the LED display is like the brain, which is responsible for commanding the lamp beads to light up.

If there is a problem with the control system, just like the brain is confused, the command will be messed up, the light of the lamp beads will be different, and the color will be messed up. IC is like a small commander on the display, responsible for controlling the refresh and display of the lamp beads.

If the IC is of poor quality or becomes old after long use, it will be like the little commander is weak or confused, the command will be inaccurate, the color on the display will be wrong, and a color difference will appear.

5). Influence of environmental factors

The LED display screen will have different display effects when placed in different places. For example, if it is placed in a place with strong sunlight, the color of the display screen may be covered by the sunlight and cannot be seen clearly.

In addition, if the ambient temperature is too high or too low, and the humidity is too high or too low, it will affect the light emission of the lamp beads.

Just like people will feel uncomfortable in an environment that is too hot or too cold, the lamp beads will also emit unstable light and change color due to a bad environment so that color differences will appear on the display screen.

Therefore, in order to make the LED display screen last longer and look good, you must pay attention to these aspects, choose good lamp beads and materials, do a good job of craftsmanship, ensure stable power supply, take good care of the control system and IC, and place it in a suitable environment.

2. What should I do if your LED display screen has a color difference?

The color difference of the LED display screen is a very distressing thing. If you encounter this problem, you can try the following operations:

1). Check the power supply and connection:

First, carefully check whether the power cord of the display is firmly plugged into the power socket to ensure that there is no looseness or poor contact. At the same time, confirm that the power socket itself is stable, and there is no voltage fluctuation or fault.

Next, check the connection cables between the display and the computer or other signal sources, such as HDMI cables, VGA cables, etc., to ensure that they are not damaged, broken, or loose. If you find any problems, try to re-plug or replace the connection cables with new ones.

2). Adjust the display settings:

Enter the settings menu of the display, which can usually be done through the remote control or buttons on the display. In the settings menu, find parameters such as brightness, contrast, and color temperature and try to adjust them appropriately.

For example, if the display is overall dim, you can increase the سطوع appropriately; if the color is cool or warm, you can adjust the color temperature to make the color more natural.

3). Observe the ambient light:

Pay attention to the ambient light around the display. Too strong light may cause the display to reflect and affect the viewing effect; too weak light may make the display appear too bright and dazzling.

Try to adjust the indoor light or use blackout curtains, curtains, etc., to reduce the interference of external light. If possible, move the display to a place with more suitable light.

4). Contact after-sales service:

If the above methods have been tried, but the color difference problem still exists, it may be a problem with the display itself.

At this time, it is best not to disassemble or repair it by yourself to avoid causing greater damage. It is recommended to contact the after-sales service department of the display, explain the problem, and ask them to send professionals to inspect and repair it.

3. How to prevent the occurrence of color differences in LED display screens

1). Choose high-quality materials and components

- LED lamp bead selection:

LED lamp beads with well-known brands, stable luminous performance, and consistent color temperature should be preferred.

At the same time, pay attention to the heat dissipation performance of the lamp beads, and choose products with good heat dissipation effect to avoid color difference problems caused by high temperature.

When purchasing, strictly inspect the quality of the lamp beads to ensure that they meet the requirements for use.

- Phosphor and packaging materials:

Choose high-quality phosphors and ensure that they are evenly applied and the coating thickness is consistent to avoid low color temperature or yellowing.

During the packaging process, reliable packaging materials, such as AB glue, should be used, and the curing conditions should be strictly controlled to prevent yellowing caused by high temperature or long-term baking.

2). Optimize the production process

- Packaging process control:

Use advanced packaging technology to ensure the packaging quality of the lamp beads.

During the packaging process, attention should be paid to details such as the application method of the phosphor and the curing conditions of the packaging glue to avoid color differences caused by improper processes.

At the same time, the monitoring of the production process should be strengthened to ensure that each step meets the process requirements.

- Spectrophotometric and color separation management:

During the production process, the LED lamp beads should be accurately spectrophotometric and color separated to ensure that the color temperature of the lamp beads in the same batch is consistent.

For different batches of lamp beads, strict color difference control should be carried out to avoid color difference problems caused by mixing.

- Mixed materials and batch management:

Strictly control the mixing problems in the production process to avoid color difference caused by using materials from different batches.

For different batches of materials, clear batch management should be carried out to ensure that the same batch of display screens use the same batch of materials to reduce the possibility of color difference.

3). Ensure the stability of the power supply system

- Power supply selection and wiring:

Select a power supply with reliable quality to ensure that the power supply system is stable and reliable. The rated power output voltage and current of the power supply should meet the needs of the display screen.

At the same time, the power supply line should be arranged reasonably to avoid voltage drop and current instability caused by too long or too thin power supply lines.

Check the connection of the power supply line regularly to ensure that it is firm and reliable.

4). Strengthen the quality control of the control system and IC

- IC selection and debugging:

Select good quality IC to ensure the refresh frequency and display screen stability of the display screen. When purchasing, the compatibility and stability of the IC should be strictly tested to avoid color differences caused by IC problems.

At the same time, the control system should be carefully debugged to ensure that the signal transmission and processing are accurate.

5). Improve the installation environment

- Heat dissipation and dust and moisture-proof measures:

Install a cooling fan or heat sink on the back of the display screen to improve the heat dissipation efficiency and avoid color differences caused by excessive temperature. At the same time, ensure that there is enough ventilation space around the display screen to avoid heat accumulation.

Set up a dust cover or dust net around the display screen to reduce dust accumulation; use a moisture-proof agent or dehumidifier in a humid environment to reduce the impact of humidity on the display screen.

6). Regular maintenance and testing

- Cleaning and performance testing:

Clean the display surface and internal components regularly to avoid the accumulation of dust and dirt that may cause color difference problems. Use a soft, clean cloth to gently wipe the display surface, and avoid using chemical solvents or overly wet items.

At the same time, performance tests on the display should be regularly performed, including testing of parameters such as brightness, contrast, and color temperature, to promptly detect and deal with potential color difference problems.

7). Use advanced correction technology

- Application of point-by-point correction technology:

Use point-by-point correction technology to collect and correct data for each pixel on the display. By generating a correction coefficient matrix and feeding it back to the display control system, the differential drive of pixels is achieved, and the differences in brightness and color are reduced.

This technology can effectively improve the display effect and consistency of the display and reduce the occurrence of color difference problems.

خاتمة

There are many reasons why LED display screens have color difference after long-term use.

Through reasonable heat dissipation design, selection of high-quality materials, stable power supply system, enhanced maintenance and reasonable use and operation, the color difference problem of LED display screens can be effectively reduced and the display effect and user experience can be improved.

وأخيرًا، إذا كنت تريد معرفة المزيد عن شاشات العرض LED، يرجى الحصول على اتصال معنا.