مقدمة

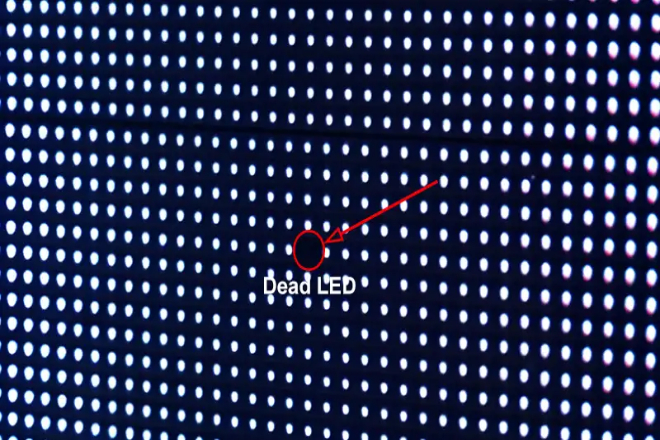

بسبب الاستخدام طويل الأمد أو العوامل الخارجية، عرض الصمام قد تتعرض حبات مصباح شاشة LED للتلف في بعض الأحيان، مما لا يؤثر على تأثير العرض فحسب، بل قد يتداخل أيضًا مع النقل الدقيق للمعلومات.

لذلك، فإن وضع علامات دقيقة وفي الوقت المناسب على حبات المصباح التالفة أمر بالغ الأهمية لأعمال الإصلاح والاستبدال اللاحقة. ولكن كيف يتم وضع علامات عليها؟

1. لماذا تحتاج إلى وضع علامة عندما تجد أن حبات المصباح مكسورة؟

عندما تجد أن حبات مصباح شاشة LED مكسورة، فلماذا تحتاج إلى وضع علامة عليها؟ هناك عدة أسباب مهمة وراء ذلك:

1) سهولة التعرف عليها وإصلاحها:

يمكن تحديد المشكلة بسرعة عن طريق وضع علامة على حبات المصباح المكسورة، مما يجعل من المناسب لموظفي الصيانة التحقق منها وإصلاحها بسرعة.

في أنظمة الإضاءة واسعة النطاق أو ترتيبات الإضاءة المعقدة، قد يكون من الصعب العثور بسرعة على حبات المصباح المكسورة وغير المميزة، مما يؤدي إلى إطالة وقت الصيانة.

2) تحسين كفاءة العمل:

من خلال وضع العلامات، يمكن لموظفي الصيانة الذهاب مباشرة إلى منطقة المشكلة دون الحاجة إلى التحقق من كل حبة مصباح واحدة تلو الأخرى، وبالتالي توفير الوقت.

وهذا مهم بشكل خاص للأماكن التي تحتاج إلى استعادة الإضاءة فيها بسرعة (مثل مراحل، أماكن الأداء، مراكز التسوق، إلخ.).

- . منع المخاطر المتعلقة بالسلامة:

قد تتسبب حبات المصباح المكسورة في حدوث مشكلات في الدائرة الكهربائية أو حدوث ماس كهربائي. ويمكن تجنب المخاطر المحتملة المتعلقة بالسلامة عن طريق وضع علامات عليها واستبدالها في الوقت المناسب. وفي بعض الحالات، قد تتسبب حبات المصباح المكسورة في عدم استقرار نظام الإضاءة بالكامل وزيادة خطر نشوب الحرائق.

4) إدارة التسجيل والصيانة:

يساعد تحديد حبات المصباح المكسورة وتسجيل مواقعها في إنشاء سجل صيانة وتوفير مرجع للإصلاحات والاستبدالات المستقبلية.

وهذا مفيد جدًا للصيانة وإدارة أنظمة الإضاءة الكبيرة على المدى الطويل ويمكنه تتبع وتيرة الاستبدال وعمر حبات المصباح.

5) التحكم في التكاليف:

من خلال تحديد واستبدال حبات المصباح المكسورة في الوقت المناسب، يمكن تجنب الأضرار الأوسع الناجمة عن عدم الإصلاح على المدى الطويل، وبالتالي توفير تكاليف الإصلاح. قد يؤدي الاستمرار في استخدام حبات المصباح المكسورة إلى زيادة استهلاك الطاقة.

إن وضع علامات على حبات المصابيح المكسورة واستبدالها في الوقت المناسب يمكن أن يساعد في توفير الطاقة وتقليل الانبعاثات. باختصار، يعد وضع علامات على حبات المصابيح المكسورة طريقة إدارة فعالة تساعد في تحسين كفاءة الصيانة، ومنع المخاطر المتعلقة بالسلامة، وتسجيل تاريخ الصيانة، والتحكم في التكاليف.

ولذلك، يتم اعتماد هذه الممارسة على نطاق واسع في الصيانة اليومية وإدارة أنظمة الإضاءة.

2. ما هي الطرق الخاطئة لوضع علامة على حبات المصباح المكسورة؟

إذا كانت طريقة وضع علامة على حبات المصباح المكسورة غير مناسبة، فقد يؤدي ذلك إلى حدوث ارتباك أو سوء فهم أو إصلاح غير فعال. فيما يلي بعض الأخطاء المحتملة عند وضع علامة على حبات المصباح التالفة:

1) علامات غير واضحة أو غامضة:

إذا كانت طريقة وضع العلامات المستخدمة ليست واضحة أو سهلة التلاشي، مثل رسم دائرة خفيفة على حبة المصباح بقلم رصاص أو استخدام ملصقات يسهل سقوطها، فقد يصبح من الصعب التعرف على العلامات أو حتى تختفي تمامًا بمرور الوقت.

سيؤدي هذا إلى دفع موظفي الصيانة إلى البحث عن حبة المصباح التالفة أثناء الفحص، مما يؤدي إلى زيادة عبء العمل.

2) وضع العلامة غير الصحيح:

إذا لم تكن العلامة مثبتة مباشرة على حبة المصباح التالفة أو مثبتة في موضع يمكن إخفاؤه بسهولة، مثل جانب أو أسفل حبة المصباح، فعند تشغيل الشاشة، قد يتم حجب العلامات بواسطة الضوء ويصبح من الصعب العثور عليها.

بالإضافة إلى ذلك، إذا تم تثبيت العلامة في موضع يسهل سقوطه أو تآكله، مثل بالقرب من دبابيس حبة المصباح، فقد يتسبب ذلك أيضًا في فشل العلامة.

3) طرق وضع العلامات غير المتسقة:

إذا استخدم موظفو الصيانة المختلفون طرق وضع علامات مختلفة أثناء عملية الإصلاح، مثل استخدام البعض للملصقات، واستخدام البعض الآخر للأقلام، واستخدام البعض الآخر للملصقات، فقد يؤدي هذا إلى حدوث ارتباك.

عندما يتولى آخرون أعمال الإصلاح، فقد يستغرق الأمر وقتًا إضافيًا لتفسير هذه العلامات، مما يقلل من كفاءة العمل.

4) معلومات تصحيحية غير كاملة أو خاطئة:

إذا كانت العلامة تحتوي فقط على معلومات موقع حبة المصباح التالفة ولكنها لا تحتوي على معلومات مهمة أخرى (مثل طراز حبة المصباح والمواصفات وتاريخ الاستبدال وما إلى ذلك)، فقد تتم مواجهة صعوبات إضافية عند استبدال حبة المصباح.

بالإضافة إلى ذلك، إذا كانت معلومات العلامة خاطئة (مثل وضع علامة خاطئة على حبة مصباح جيدة على أنها حبة مصباح سيئة)، فسيؤدي ذلك إلى أعمال إصلاح غير ضرورية.

5) استخدم مواد أو أدوات هشة:

في حالة استخدام مواد هشة (مثل الورق العادي والشريط اللاصق وما إلى ذلك) أو أدوات (مثل الأشياء الحادة) لوضع علامة على حبة المصباح التالفة، فقد يتسبب ذلك في إتلاف العلامة أو خدوش على سطح حبة المصباح.

لن يؤثر هذا على وضوح العلامة فحسب، بل قد يتسبب أيضًا في إتلاف حبة المصباح نفسها.

3. ما هي طريقة وضع العلامات الفعالة على حبات المصباح التالفة على شاشات العرض LED؟

بالنسبة لحبات المصباح التالفة على شاشات العرض LED، فإن طرق وضع العلامات الفعّالة ضرورية لتحسين كفاءة الإصلاح ودقته. فيما يلي طرق وضع العلامات التفصيلية والمحددة، بالإضافة إلى الاحتياطات والاقتراحات ذات الصلة:

1) استخدم ملصقات أو علامات احترافية للتمييز

1.1). اختر ملصقات أو بطاقات عالية الجودة

- مقاوم للماء والزيت:

تأكد من أن الملصقات أو العلامات يمكن أن تظل شفافة ولزجة في ظل ظروف بيئية مختلفة ولن تتساقط أو تتشوش بسبب الرطوبة أو الشحوم.

- متانة:

اختر الملصقات أو العلامات التي يمكنها الحفاظ على الوضوح واللون لفترة طويلة حتى يمكن التعرف بدقة على حبات المصباح التالفة أثناء عملية الإصلاح وبعدها.

- قابلية التمزق:

يجب أن يكون من السهل إزالة الملصق أو العلامة دون ترك بقايا غراء أو إتلاف لوحة الدائرة المحيطة بحبة المصباح.

1.2). تصميم محتوى واضح للعلامات

- تحديد واضح:

قم بوضع علامة واضحة على الكلمات "حبة مصباح سيئة" أو "تحتاج إلى استبدال" على الملصق أو البطاقة حتى يتمكن موظفو الصيانة من رؤيتها في لمحة.

- معلومات الموقع:

قم بتضمين رقم الصف والعمود أو الإحداثيات المحددة لخرزة المصباح على شاشة العرض لتحديد الموضع بسرعة.

- سجل الصيانة:

إذا كان ذلك ممكنًا، يمكنك أيضًا تسجيل تاريخ الاستبدال، وأفراد الصيانة، وغيرها من المعلومات على الملصق أو البطاقة للتتبع والإدارة اللاحقة.

1.3). قم بلصق الملصق أو العلامة بشكل صحيح

- اختيار الوظيفة:

قم بلصق الملصق أو العلامة مباشرة على الجزء العلوي من حبة المصباح أو في مكان واضح لتجنب حجبه بواسطة أجزاء أخرى.

وفي الوقت نفسه، تأكد من أن موضع اللصق لن يؤثر على تبديد الحرارة والتأثير الضوئي لخرز المصباح.

- لصق مسطح:

تأكد من أن الملصق أو العلامة تم لصقها بشكل مسطح لتجنب الفقاعات أو التجاعيد حتى لا تؤثر على قابليتها للقراءة وجماليتها.

2) استخدم قلمًا أو علامة لكتابة العلامات

2.1). اختر علامة أو علامة مناسبة

- مقاوم للماء والزيت:

تأكد من أن المحتوى المكتوب يمكن أن يظل واضحًا ودائمًا في ظل الظروف البيئية المختلفة.

- لون جذاب للنظر:

اختر علامة أو قلمًا بلون جذاب لتحديد حبات المصباح التالفة على الشاشة بسرعة.

2.2) توحيد المحتوى المكتوب

- حدد بوضوح:

اكتب "خرز المصباح التالف" أو "استبدله" بقلم أو علامة على لوحة الدائرة أو في أماكن بارزة أخرى بالقرب من خرز المصباح.

- معلومات الموقع:

قم بتضمين رقم الصف والعمود أو الإحداثيات المحددة لخرزات المصباح على الشاشة لضمان تمكن موظفي الصيانة من تحديد موقعها بسرعة.

- مواصفات الكتابة:

يجب أن يكون المحتوى المكتوب واضحًا ومرتبًا، وتجنب الكلمات غير الواضحة أو غير المنسقة التي تجعل من الصعب التعرف عليها.

2.3). انتبه إلى وضع الكتابة والحماية

- تجنب المناطق الحساسة:

تأكد من أن وضع الكتابة لن يتسبب في إتلاف حبات المصباح أو التأثير على التشغيل العادي للشاشة. على سبيل المثال، تجنب الكتابة بالقرب من دبابيس حبات المصباح أو المناطق الحساسة على لوحة الدائرة.

- منع التآكل والتلف:

أثناء عملية الصيانة، انتبه إلى حماية المحتوى المكتوب من التآكل أو المسح. يمكنك تغطيته بطبقة من الشريط الشفاف أو الفيلم الواقي بعد الكتابة.

3) استخدم طريقة العلامات الرقمية أو الرسومية

3.1). التعريف الرقمي أو الرسومي

- رقم الصف والعمود أو الرقم:

على لوحة الدائرة أو في أماكن بارزة أخرى بالقرب من حبة المصباح، استخدم علامات رقمية أو رسومية لتحديد معلومات موضع حبة المصباح (مثل رقم الصف والعمود والرقم وما إلى ذلك).

تعتبر هذه الطريقة مناسبة لشاشات العرض الكبيرة أو سيناريوهات الصيانة التي تتطلب تحديد المواقع بدقة.

- الترميز اللوني:

يمكن استخدام ألوان أو أشكال مختلفة لتمثيل أنواع مختلفة من الأضرار (مثل الدوائر القصيرة، والدوائر المفتوحة، وما إلى ذلك) حتى يتمكن أفراد الصيانة من التعرف عليها ومعالجتها بسرعة.

4) احتياطات واقتراحات أخرى

4.1) الحفاظ على اتساق العلامات

يجب الحفاظ على اتساق العلامات طوال عملية الصيانة. سواء باستخدام الملصقات أو العلامات أو العلامات أو أنظمة العلامات الإلكترونية، يجب اتباع مواصفات ومعايير العلامات الموحدة.

4.2) حماية العلامة من التلف

أثناء عملية الصيانة، انتبه إلى حماية العلامة من التلف أو السقوط. خاصة عند إزالة واستبدال حبات المصباح، كن حريصًا على تجنب إتلاف العلامة.

4.3) التحقق من العلامات وتحديثها بشكل منتظم

قم بالتحقق بانتظام من وضوح ودقة العلامات، وقم باستبدال العلامات غير الواضحة أو المتساقطة في الوقت المناسب.

وفي الوقت نفسه، وفقًا لتقدم الصيانة والظروف الفعلية، يتم تحديث معلومات العلامات لضمان قدرة موظفي الصيانة على فهم المشكلة بدقة.

4.4) التدريب والتوجيه

تدريب وإرشاد موظفي الصيانة للتأكد من قدرتهم على فهم واستخدام طريقة وضع العلامات بشكل صحيح. يساعد هذا في تحسين كفاءة ودقة الصيانة وتقليل احتمالية سوء التقدير والإهمال.

4. الاحتياطات والمعالجة اللاحقة

1). احتياطات السلامة

عند إجراء عمليات الفحص أو الصيانة على شاشات العرض LED، تأتي السلامة دائمًا في المقام الأول. فيما يلي بعض احتياطات السلامة المهمة:

1.1). عملية إيقاف التشغيل:

قبل إجراء أي فحص أو صيانة، من الضروري التأكد من إيقاف تشغيل دائرة شاشة العرض LED بالكامل.

يمكن تحقيق ذلك عن طريق إيقاف تشغيل مفتاح الطاقة، أو فصل سلك الطاقة، أو استخدام جهاز اختبار الدائرة للتأكد من قطع الطاقة.

يتم إيقاف تشغيل الطاقة لتجنب خطر التعرض لصدمة كهربائية وحماية سلامة حياة أفراد الصيانة.

1.2). التشغيل المهني:

إذا لم يكن المستخدم متأكدًا من كيفية إجراء عملية الفحص أو الصيانة بشكل صحيح، فمن الأفضل أن يطلب من متخصص يتمتع بالخبرة والمؤهلات ذات الصلة القيام بذلك.

يتمتع المحترفون بالمعرفة والمهارات اللازمة لإكمال مهام الصيانة بشكل أكثر أمانًا وفعالية.

1.3). الحماية الشخصية:

يجب على أفراد طاقم الصيانة ارتداء معدات الحماية الشخصية المناسبة، مثل القفازات العازلة، ونظارات السلامة، وما إلى ذلك، أثناء التشغيل.

يمكن أن توفر هذه المعدات حماية إضافية وتقلل من خطر الإصابة العرضية.

2) خطوات المعالجة اللاحقة

بعد تحديد حبات المصباح التالفة، فإن الخطوة التالية هي شراء حبات مصباح بديلة واستبدالها. فيما يلي الخطوات المحددة وتعليمات السلامة للمعالجة اللاحقة:

2.1) شراء حبات مصباح بديلة:

وفقًا لمعلومات العلامة، حدد طراز ومواصفات وكمية حبات المصباح التالفة.

اتصل بالمورد أو الشركة المصنعة لشراء حبات مصباح بديلة للطراز المقابل. تأكد من أن حبات المصباح البديلة متوافقة مع حبات المصباح الأصلية من حيث الخصائص الكهربائية والحجم وطريقة التركيب.

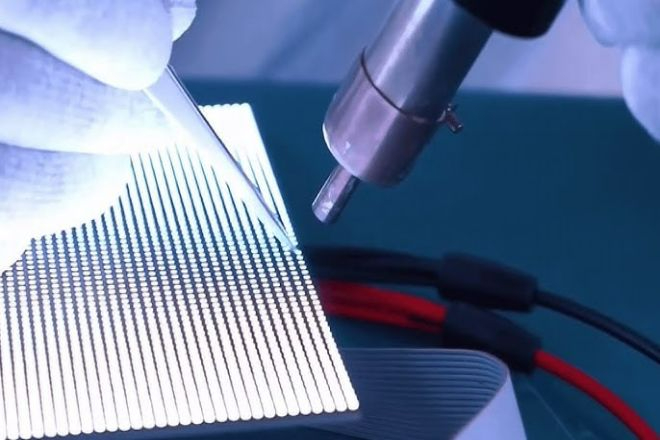

2.2). الخطوات الأساسية لاستبدال حبات مصباح LED:

- تحضير الأدوات والمواد:

قم بإعداد أدوات اللحام (مثل محطة اللحام، وسلك اللحام، والمواد المضافة، وما إلى ذلك)، والملاقط، ومفكات البراغي، والأدوات الضرورية الأخرى، بالإضافة إلى حبات المصباح البديلة.

- إزالة حبات المصباح التالفة:

تأكد مرة أخرى من أن الدائرة متوقفة عن التشغيل.

استخدم الملقط أو مفكات البراغي لرفع دبابيس حبات المصباح التالفة بلطف وإزالتها من لوحة الدائرة.

احرص على إبقاء الدبابيس ولوحات الدوائر سليمة لتجنب إتلاف المكونات الأخرى.

- قم بتثبيت حبة المصباح البديلة:

وفقًا لتحديد قطبية حبة المصباح (عادةً مع علامات موجبة وسالبة)، قم بتحديد حبة المصباح البديلة وإدخالها بشكل صحيح.

استخدم ملقطًا أو مفكًا لتثبيت حبة المصباح برفق، مع التأكد من محاذاة دبابيسها مع الوسادات الموجودة على لوحة الدائرة.

- لحام حبة المصباح:

استخدم محطة اللحام لتسخين سلك اللحام ولحام دبابيس حبة المصباح بقوة بالوسادات الموجودة على لوحة الدائرة.

انتبه إلى التحكم في درجة حرارة اللحام والوقت لتجنب ارتفاع درجة الحرارة وإتلاف حبة المصباح أو لوحة الدائرة.

بعد اللحام، استخدم مادة اللحام لإزالة بقايا خبث اللحام والأوساخ للحفاظ على لوحة الدائرة نظيفة.

- تعليمات السلامة:

كن دائمًا يقظًا وانتبه للسلامة الشخصية أثناء العمليات.

تجنب لمس المكونات أو الدبابيس المكشوفة على لوحة الدائرة لتجنب الصدمات الكهربائية أو إتلاف المكونات.

عند استخدام أدوات اللحام، اتبع طرق التشغيل الصحيحة لتجنب الحوادث مثل الحروق أو الحرائق.

بعد اكتمال عملية الاستبدال، تحقق مرة أخرى مما إذا كان الاتصال على لوحة الدائرة ثابتًا للتأكد من عدم وجود ارتخاء أو ماس كهربائي.

أخيرًا، قم بتشغيل شاشة LED للاختبار والتأكد من أن حبة المصباح البديلة تعمل بشكل صحيح دون وميض أو ظواهر غير طبيعية.

باختصار، يعد تحديد حبة المصباح التالفة مجرد الخطوة الأولى في عملية الإصلاح. في المعالجة اللاحقة، من الضروري أيضًا الانتباه إلى مواصفات التشغيل الآمن وشراء واستبدال حبات المصباح البديلة بشكل صحيح، والتأكد من أن شاشة LED التي تم إصلاحها يمكن أن تعمل بشكل صحيح.

إذا لم تكن متأكدًا من كيفية التشغيل أو تفتقر إلى الخبرة ذات الصلة، فمن الأفضل أن تطلب المساعدة أو التوجيه من المتخصصين.

خاتمة

من خلال مقدمة هذه المقالة، تعلمنا مجموعة متنوعة من طرق وضع العلامات على حبات مصباح شاشة LED التالفة، وكل خطوة مصممة لضمان إمكانية تحديد حبات المصباح التالفة بدقة وسرعة.

لا تعمل طرق وضع العلامات هذه على تحسين كفاءة الصيانة فحسب، بل إنها تعمل أيضًا على تقليل تكلفة الصيانة وإهدار الوقت الناجم عن سوء التقدير أو الإهمال.

أخيرًا، إذا كنت تريد معرفة المزيد عن شاشات LED، يرجى الحصول على اتصال معنا.