مقدمة

We all know that the outdoor environment is complex and changeable. Harsh weather conditions, extreme temperature changes, dust pollution, lightning, and other natural factors all pose severe challenges to the service life of شاشات LED خارجية.

When facing these harsh environments, traditional LED displays are often prone to brightness attenuation, color distortion, and even fault damage, which seriously affects their use effect and reliability. However, COB LED displays that have appeared in recent years can “survive” well. Why is this?

1. Introduction to technical features and advantages of COB LED modules

1). Packaging technology

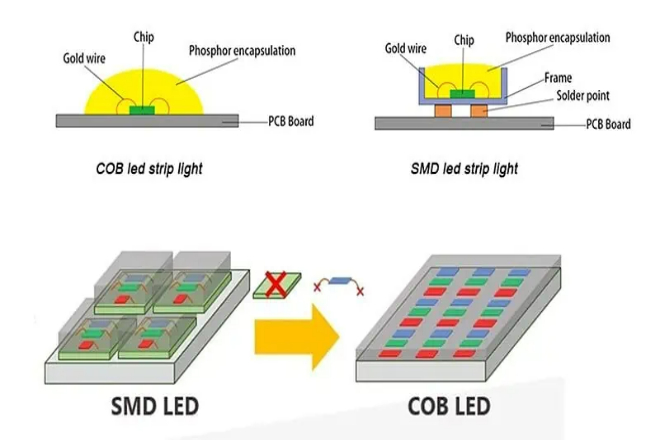

COB packaging technology, to put it bluntly, is to stick the LED chip directly to the printed circuit board (PCB), and then seal it with a layer of epoxy resin or other materials. In this way, the LED chip becomes part of the circuit board, eliminating many traditional packaging steps.

Compared with traditional SMD packaging, COB packaging is simpler and more efficient. It eliminates the troublesome steps of lamp bead packaging and reflow soldering, making production faster and easier.

Moreover, because the LED chip is directly attached to the circuit board, the pixel pitch can be made smaller, and the picture looks clearer and more delicate.

Another advantage of COB packaging is that it is particularly stable. Because the chips are sealed inside the circuit board, they are not afraid of falling or collision. In addition, its heat dissipation performance is good, and the LED chip is not easy to overheat, so the display life is longer.

2). Heat dissipation performance

COB packaging directly attaches the LED chip to the circuit board so that the heat generated by the chip can be directly dissipated through the circuit board.

Just like when you put your hand on an ice cube, the heat will be quickly transferred away. In this way, the LED chip will not break down due to overheating, and the display will last longer.

Heat dissipation is very important for LED displays. If the heat dissipation is not good, the LED chip will age and light decay due to overheating, and the life of the display will be short.

COB packaging technology has good heat dissipation, so the life of the display is longer and it is more reliable to use.

3). Protection level

COB packaging technology seals the LED chip tightly, and dust and moisture cannot get in. Moreover, its surface is hard and not afraid of collision. In this way, the display screen can work well in harsh outdoor environments without worrying about being hit by wind, rain, or collision.

The outdoor environment is very harsh, with dust, water and possible collision. But COB packaging technology is not afraid of these, it is dustproof, waterproof and collision-proof. Therefore, the display screen with COB packaging is particularly suitable for outdoor use, without worrying about damage or poor display effect.

4) التأثير البصري

The display screen with COB packaging technology has a very wide viewing angle, almost 180 degrees. In this way, no matter where you look, the picture is clear. Moreover, its optical performance is also very good, and it looks like being immersive.

The outdoor LED display screen is to attract people’s attention. Wide viewing angles and clear pictures can attract more people to watch.

The display screen with COB packaging technology has achieved this, so it is particularly popular for outdoor use. Whether it is advertising or displaying information, the effect is particularly good.

2. What are the impacts and challenges of harsh environments on outdoor LED screens?

1). Analysis of environmental factors

1.1). The impact of bad weather on outdoor LED screens

1.1.1). Heavy rain and snowstorms:

When heavy rain and snowstorms come, outdoor LED screens will suffer. Rainwater seeping in may cause the screen to short-circuit, dead lights, and even corrosion of the electronic components inside. Snow piled on it may also crush the screen or cause problems with the screen’s connection.

1.1.2). Extreme temperature:

- درجة الحرارة المنخفضة:

When it is too cold, the material of the LED screen will shrink, gaps may appear between modules, and the lamp beads may loosen, resulting in abnormal display. Moreover, things become brittle when cold, and the screen is easy to break.

- درجة حرارة عالية:

When it is hot, the LED screen is not as bright as before because the lamp beads decay quickly. High temperature may also cause the screen to deform or even short-circuit. Safety first!

1.2). Damage to the screen surface by dust, pollutants, etc.

When dust and dirt pile up on the LED screen, the picture becomes blurred and it is difficult to see clearly. These things will also block the light and make the screen darker. Over time, the surface of the screen may be corroded and it will have to be replaced soon.

1.3). Potential threats of lightning to electronic devices

Lightning is the natural enemy of electronic devices. When lightning strikes, the power supply of the LED screen may burn out, and the chip and lamp may also be broken down. Even if the lightning does not strike directly, the induced current may damage the screen. Therefore, lightning protection measures must be taken.

It is really not easy for outdoor LED screens to operate in harsh environments. Water, dust, dirt, lightning, any of them can cause problems. Abnormal display, performance degradation, or even direct damage are all possible.

Therefore, outdoor LED screens must be waterproof, dustproof, and lightning-proof to last for a long time. Choosing the right LED module is very important for outdoor screens.

3. What are the application strategies of COB LED modules in harsh environments?

1). Waterproof and dustproof design

Outdoor LED display screens often face wind and rain, and dust is everywhere. If the waterproof and dustproof design is not done well, rainwater seeps in, the circuit may short-circuit, and the lamp beads may also be damaged due to water ingress.

Dust accumulation on the screen will not only affect the clarity of the picture but also corrode the screen surface and shorten the life of the display. Therefore, waterproof and dustproof design is very important for outdoor LED displays, just like putting on a layer of protective clothing for it.

The design of the COB LED module is really clever.

It sticks the LED chip directly to the PCB board and then encapsulates it with materials such as epoxy resin, just like putting on a thick layer of armor for the chip. In this way, it is difficult for water and dust to penetrate.

Compared with traditional SMD packaging, the COB module has stronger waterproof and dustproof performance because it has no exposed pins and solder joints, and it is easier to seal. Therefore, in such harsh outdoor environments, COB modules are particularly suitable.

2). Lightning protection measures

The power of lightning is great. When a lightning strikes, the power supply of the equipment may be burned instantly, and the chip and circuit may also be broken down.

Outdoor LED display screens are more likely to become targets of lightning because of their large size and high position.

Therefore, lightning protection measures are like installing an insurance for outdoor LED display screens to ensure that it can operate safely in thunderstorms.

Installing a lightning protection system is actually quite particular. First, lightning rods or lightning strips must be installed around the display screen so that lightning will be directly led underground and will not strike the display screen.

Then, surge protectors must be installed on the power and signal lines of the display screen to prevent lightning-induced currents from damaging the equipment.

When installing, the layout, height, and surrounding environment of the display screen must be considered comprehensively to ensure the best lightning protection effect.

COB modules perform very well in lightning protection systems. Because of its simple structure and simple circuit, the impact of lightning-induced current on it is relatively small.

Moreover, COB modules have high integration and good stability and can maintain stable operation even in thunderstorms. Therefore, outdoor LED displays made of COB modules are more secure in terms of lightning protection.

3). Temperature control

High and low temperatures are not friendly to LED displays. When it is hot, the LED chip heats up, the light decays faster, and the life is shortened. When the temperature is high, the lamp may die, and the brightness decreases.

When it is cold, the screen material shrinks, the lamp beads loosen, and the picture becomes blurred. Therefore, the temperature control must keep up, just like adjusting the comfort zone for the display.

The heat dissipation and heating device is actually quite simple to configure. Heat dissipation can be done by air cooling, water cooling, or heat pipe cooling. Air cooling means that the fan blows away the heat.

Water cooling means that the coolant absorbs heat; heat pipe cooling means that the heat pipe conducts heat. Heating can be done by electric heating or heat pipe heating. When configuring, it is necessary to ensure the best effect according to the power, size, and use environment of the display.

COB packaging technology has advantages in temperature control. The COB module sticks the LED chip and the PCB board tightly, and the heat conduction efficiency is high. The heat generated by the chip can be transferred out quickly and will not accumulate on the chip.

Moreover, the integration is high, the heat dissipation area is large, and it is easier to dissipate heat. The outdoor LED display screen made of a COB module has better temperature control.

4). Structural reinforcement and stable installation

The outdoor environment has strong winds and many external forces, which is not friendly to LED displays. When the wind is strong, the display screen may shake or even be blown down. Earthquakes and hail may also come to make trouble.

Therefore, structural reinforcement and stable installation must keep up, just like installing a stable frame for the display screen.

To strengthen the structure, you can use high-strength materials such as aluminum alloy and stainless steel to make the box. In this way, the box has stronger load-bearing capacity and wind pressure resistance.

The box connection must also be reinforced; screws and welding are fine to ensure a firm connection. When installing, you have to choose a stable method, such as fixing it to the wall or pillar with expansion screws. You can also surround it with fences, guardrails, etc., to prevent external forces from disrupting it.

COB modules are also very useful in enhancing the structural stability of display screens. It has high integration, small size and light weight. It is easy to install and maintain, and it is easier to ensure stability.

Moreover, the simple structure is not easy to break, which can also improve the overall stability of the display screen. The outdoor LED display screen made of COB modules has better structural stability and installation and maintenance.

خاتمة

In summary, COB LED modules have excellent performance in extending the service life of outdoor screens in harsh environments with their unique technical characteristics and advantages.

By adopting application strategies such as waterproof and dustproof design, lightning protection measures, temperature control, structural reinforcement, and stable installation, COB LED modules can effectively cope with various challenges in outdoor environments and maintain stable operation and good display effects of the display.

أخيرًا، إذا كنت تريد معرفة المزيد عن شاشات LED، يرجى الحصول على اتصال معنا.