مقدمة

ال small-pitch LED display screen is changing our information display world with its unparalleled visual impact. But are you curious about how the technical mystery behind this – especially the packaging technology – determines the excellent performance of the screen?

In particular, does the small-spacing LED display really have to adopt the popular COB packaging technology?

This article will take you to deeply explore the packaging world of small-pitch LED display screens. It not only reveals the unique charm of COB technology, but also compares the advantages and disadvantages of other packaging methods, so that you can understand what technology is the wisest to choose in what situation.

1. The development background of small-spacing LED display

Imagine how this change happened from the huge and single-color LED billboards in the early days to the delicate, full-color small-spacing LED TV wall that can be viewed up close at home today?

Behind this is the development process of a small-pitch LED display. At first, LED display screens were mainly used for outdoor large-scale advertising, but with the advancement of technology, especially the continuous narrowing of pixel spacing, LED display screens began to enter indoors and became the small-spacing LED displays we know today.

With the rapid development of technology, people have higher and higher requirements for the clarity of the picture. Just like from black-and-white TV to color TV to high-definition TV, the emergence of small-spacing LED displays is precisely to meet people’s pursuit of higher-definition and more realistic images.

It makes the image more delicate and the color fuller by increasing the number of LED lamp beads in the unit area.

2. Introduction to COB packaging technology

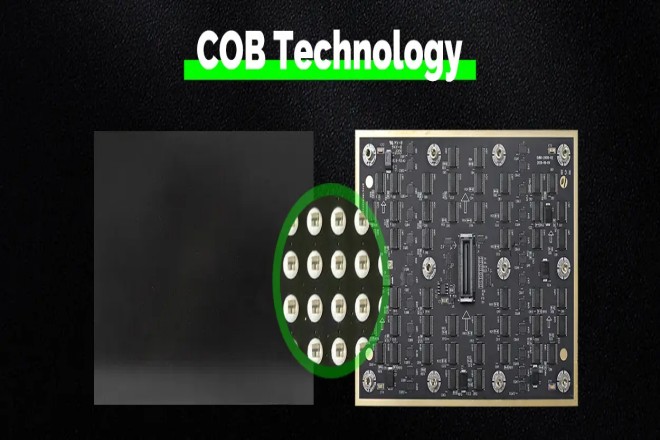

Imagine if you have an ultra-small LED bulb (we call it an LED chip). Instead of putting it in a small box and putting it on the circuit board, directly “stick” the light bulb on the circuit board.

This is the كوب (chip on the board) packaging technology. It is like “drawing” the LED lamp directly on the circuit board, making the connection between the lamp and the circuit board more direct and closer.

What are the advantages of COB packaging?

- Brighter and clearer:

Because the LED chip is directly attached to the circuit board, the light will not be blocked by the packaging material, so the screen looks brighter. At the same time, the distance between each LED chip is also closer so that the displayed image is more delicate and clear.

- More durable:

In the COB package, the connection between the LED chip and the circuit board is stronger and not easy to fall off. This means that our screens are more durable and not easy to break.

- تبديد الحرارة بشكل أفضل:

Because the LED chip is directly attached to the circuit board, the heat can be emitted faster without making the screen too hot. In this way, the screen can be kept in good condition for a longer time, and there will be no failure caused by overheating.

3. What will happen if the small-pitch LED display is not packaged with COB?

If the small-pitch LED display does not adopt COB packaging technology, the following problems may be encountered.

1). The picture is not clear enough.

Imagine that you are looking at a painting. If the dots on the painting are very large, the whole painting will look blurry. Similarly, if the dots on the LED display (we call pixel dots) are large, the displayed picture will not be clear enough.

It is difficult for traditional packaging technology to make very small pixels, so the picture may look a little “granular.” However, if COB packaging technology is used, smaller pixels can be made to make the picture look clearer and more delicate.

2). The lamp is easy to break and troublesome to repair.

In traditional packaging technology, LED lights are pasted on the circuit board like “sticking beans.” However, these “beans” easily fall off for various reasons (such as vibration during transportation or collision during use), resulting in “black spots” or “unbright spots” on the display.

Moreover, because these “beans” are pasted separately, if one is broken, the whole circuit board needs to be removed and replaced one by one, which is very troublesome. However, if COB packaging technology is used, the LED lamp is directly “long” on the circuit board, which is not easy to break and much easier to repair.

3) It is easy to get hot, which affects one’s lifespan.

The LED lamp will heat up when working. If the heat cannot be dissipated in time, the life of the LED lamp will be shortened or even directly broken.

In traditional packaging technology, it is difficult to emit heat because the connection between the LED lamp and the circuit board is not tight enough. However, if COB packaging technology is used, the connection between the LED lamp and the circuit board will be closer, and the heat can be emitted faster, making the LED lamp longer.

4. The advantages of small-pitch LED display using COB packaging.

The small-spacing LED display adopts COB packaging technology, which is like putting a “super coat” on the display screen, making it more powerful and easy to manage. Next, we will explain these advantages in simple and easy-to-understand words:

1). Image quality improvement: The picture is clearer and more delicate

Imagine that you are looking at a beautiful painting. If the brushstrokes of this painting are very large, what you see may be some large colors, and the details will be blurred. However, if the strokes are small and thin, you can see more details, and the picture will be more realistic.

The same is true for small-pitch LED display screens.

In the traditional LED display screen, because the lamp beads are relatively large, the picture displayed is like a painting drawn with a large brush, and the details are not clear enough. However, the small-spacing LED display screen using COB packaging technology is like painting with a very fine stroke, which can show more details, and the picture will be clearer and more delicate.

2). Stability enhancement: More durable and reliable

In the traditional LED display screen, the lamp beads are posted separately on the circuit board, just like a bean. However, these “beans” are easy to fall off for various reasons (such as collision and vibration), resulting in problems with the display.

And the small-pitch LED display screen with COB packaging technology is like integrating these “beans” together to form a whole. In this way, the display is less susceptible to the influence of the outside world, and becomes more durable and reliable.

3). Energy consumption reduction: More power-saving and more environmentally friendly

When the traditional LED display screen is working, it needs to consume a lot of electricity to make the lamp beads glow. However, the small-spacing LED display screen with COB packaging technology is more closely connected to the lamp beads and the circuit board, so it has higher luminous efficiency and can emit the same brightness with less electricity.

It’s like you bought a very energy-saving car, which can run the same distance with less fuel. Therefore, the small-spacing LED display screen with COB packaging technology is not only more power-saving but also more environmentally friendly.

4). Easy to maintain: Simpler and faster maintenance

In the traditional LED display screen, if a lamp bead is broken, you need to remove the whole circuit board and then find and replace it one by one, which is very troublesome. However, the small-spacing LED display screen with COB packaging technology is much easier to maintain because the lamp beads and the circuit board are whole.

It’s like the light bulb in your home is broken. You just need to replace it with a new one without removing the whole lamp. Therefore, the small-pitch LED display screen with COB packaging technology is simpler and faster to repair.

5. The future development trend of small-spacing LED display

The small-spacing LED display screen, simply put, means that the distance between the LED lamp beads becomes very small so that the displayed picture is clearer and more delicate.

Now, let’s take a look at the future development trend of this display, just like looking at what TVs or mobile phones will become in the future.

1). Encapsulation technology will be more powerful.

1.1). COB packaging technology will be more popular.

The cost will be reduced: just as the mobile phone was very expensive when it first came out, but now it has become very cheap, the cost of COB packaging technology will also gradually decrease, so that more people can afford the small-spacing LED display of this technology.

Better performance: COB packaging technology can make the picture of the display clearer, more stable, and not easy to break. In the future, this technology will become more powerful, and the display will become better.

2). Other new technologies will also appear.

Mini LED and Micro LED: These two new technologies can make the lamp beads of the display smaller and the picture more delicate. Although they are still a little expensive now, they may become cheaper in the future, and more people can use them.

New materials and new processes: Scientists will also study new materials and processes to make displays thinner, lighter, and longer.

3). It will be applied more widely.

There will be more high-end occasions, such as المدينة الذكية projects in big cities, large conference centers, or very important exhibitions; these places will use small-pitch LED displays because they have good display effects.

Ordinary families can also use it: In the future, small-spacing LED displays may become cheaper, and ordinary families can also install a large and clear display at home, which will be more refreshing to watch movies and play games.

New applications will appear: With the development of technology, small-spacing LED displays can also be combined with new technologies such as the Internet of Things and artificial intelligence to make more interesting applications that we can’t imagine now.

خاتمة

In summary, the selection of packaging technology for small-spacing LED displays is a complex and multi-dimensional decision-making process, which is not only related to the advancedness of technology but also to consider cost-effectiveness, the specificity of application scenarios, and the feasibility of technical realization.

Although COB packaging technology occupies a place in the field of small-spacing LED displays with its unique advantages, it does not mean that it is the best solution in all cases.

On the contrary, flexibly choosing the packaging method according to specific needs and balancing performance, cost, and maintainability is the key to promoting the sustainable development of small-spacing LED display technology.

أخيرًا، إذا كنت تريد معرفة المزيد عن شاشات LED، يرجى الحصول على اتصال معنا.