Introduction

In today’s digital and information age, LED displays are widely used in commercial advertising, outdoor media, stadiums, conferences and exhibitions, and other fields with their advantages of high brightness, high definition, and long life.

As the core component of LED displays, the packaging technology of lamp beads not only directly affects the display effect and service life of the display but is also the key to improving the performance of LED displays.

1. Overview of LED lamp bead packaging technology

LED lamp bead packaging is a delicate and critical manufacturing process that involves combining LED chips, electrodes, optical elements, and other necessary components into a complete LED device. The main goal of packaging is to protect the LED chip, improve the reliability of the device, and ensure that it can emit light stably and efficiently.

1). Packaging materials:

The selection of LED lamp bead packaging materials is crucial to the performance and life of LED devices. The following are common packaging materials and their characteristics:

Plastic packaging: Plastic packaging is one of the most common packaging forms for LED lamp beads. It uses plastic materials, such as epoxy resin, as packaging materials. Plastic packaging has the advantages of low cost, lightweight, and good light transmittance, and is suitable for various LED applications.

Metal packaging: Metal packaging is usually used for LED devices that require higher heat dissipation performance. Metal packaging can provide better heat dissipation and protect LED chips from overheating damage. Common metal packaging materials include aluminum, copper, etc.

Glass packaging: Glass packaging is suitable for LED devices with high requirements for light transmittance and stability. Glass packaging can provide good optical performance and stability, but the cost is relatively high.

In addition to the above materials, there are other special packaging materials, such as ceramics, silicon, etc., which have their own unique properties and application scenarios. The choice of packaging materials depends on the specific requirements and application environment of LED devices.

When selecting packaging materials, factors such as the thermal properties, mechanical strength, and chemical stability of the materials also need to be considered. For example, the packaging material should have a good thermal expansion coefficient and thermal conductivity to ensure that the LED device can maintain stability when the temperature changes.

At the same time, the packaging material should also have good mechanical strength and chemical stability to resist damage to the LED device from the external environment.

2. Key links in LED lamp bead packaging technology

1). Chip bonding: Ensure the stability of the LED chip during the packaging process.

- Wafer cleaning and inspection:

Before the wafer is fixed, the surface of the LED chip needs to be strictly cleaned to ensure that there are no impurities, such as dust and oil.

Subsequently, the size, electrode size, and dimensions of the LED chip are inspected in detail to ensure that they meet the process requirements and that the electrode pattern is complete.

- Wafer positioning and bonding:

A high-precision wafer fixing machine is used to accurately place the LED chip in the preset position, and then a layer of special conductive glue or silver glue is applied to firmly fix the chip on the substrate.

This process requires extremely high precision because the position and angle of the chip directly affect the light-emitting effect and light-emitting efficiency of the LED.

2). Gold wire welding: To achieve electrical connection between the LED chip and the external circuit.

- Gold wire selection and welding process:

LED bonding gold wire is usually made of gold (Au) with a purity of more than 99.99%. Gold wire plays the role of wire connection in LED packaging, connecting the chip surface electrode and the bracket.

The welding process usually adopts thermosonic bonding technology, using heat and ultrasound under the combined action of pressure, heat, and ultrasonic energy to weld the welding wire to the electrode and bracket of the chip.

- Welding quality inspection:

After welding is completed, the welding point needs to be inspected to ensure that there is no tin leakage, welding slag, or other problems on the pad and that necessary repairs are carried out.

3). Encapsulation molding: protect LED chips and improve device reliability

- Mold design and manufacturing:

manufacture suitable molds according to the design requirements of LED devices.

- Injection molding/filling of encapsulation materials:

Cover the selected encapsulation materials (such as plastic, glass, etc.) on the LED chips and welding points by injection molding or filling to form a complete encapsulation structure.

- Post-encapsulation processing:

Perform aging tests and performance tests on the encapsulated LED devices to ensure that they meet quality requirements.

4). Optical processing: improve the luminous efficiency and optical properties of LEDs

- Lens design and manufacturing:

design and manufacture suitable lenses according to the luminous properties and application requirements of LED devices to improve the concentration and utilization of light.

- Optical film coating:

Coat one or more optical film layers on the surface of LED devices to improve their optical properties, such as increasing brightness and reducing color temperature.

- Optical performance testing:

Use specific instruments to test the optical performance of LED devices, including parameters such as brightness, color temperature, and spot distribution, to ensure that they meet design requirements.

3. Characteristics of LED display lamp bead packaging technology

- High precision:

The lamp bead packaging technology of LED display needs to ensure the position accuracy of each LED lamp bead on the display screen to ensure that the pixels of the entire display screen are neatly arranged and clear.

At the same time, the packaging technology also needs to ensure the consistency of the light emission of each LED lamp bead, that is, all lamp beads emit light of the same brightness and color under the same conditions, thereby avoiding the problem of uneven brightness or color deviation on the display screen.

- High reliability:

The lamp bead packaging technology of LED displays focuses on improving the reliability of the product to ensure that the display screen can operate stably in various environments.

By selecting high-quality packaging materials and strict packaging processes, the lamp beads can be effectively prevented from being damaged or degraded due to external factors (such as temperature, humidity, vibration, etc.).

In addition, the packaging technology can also effectively prevent pollutants such as moisture and dust from entering the interior of the lamp beads, further improving the reliability of the product.

- Energy saving and environmental protection:

The lamp bead packaging technology of LED display screens usually adopts low-power LED chips and high-efficiency packaging technology to reduce energy consumption.

Low-power LED chips can reduce the working current and power consumption while ensuring brightness and color, thereby extending the service life of the display screen.

At the same time, efficient packaging technology can improve the photoelectric conversion efficiency of LED lamp beads, reduce energy loss, and further reduce energy consumption.

- Diversity:

The lamp bead packaging technology of LED display screens is diverse and can meet the performance requirements of LED display screens in different application scenarios.

For example, for application scenarios such as outdoor billboards that require high brightness and wide viewing angle, high-brightness, and wide-viewing angle LED lamp bead packaging technology can be used.

For application scenarios such as indoor conference rooms that require high definition and low color difference, high-resolution and low-color difference LED lamp bead packaging technology can be used.

In addition, packaging technology can also be customized according to customer needs to meet special application scenarios.

4. How many types of lamp bead packaging technologies are there for LED display screens?

The lamp bead packaging technologies of LED display screens can be mainly summarized as follows:

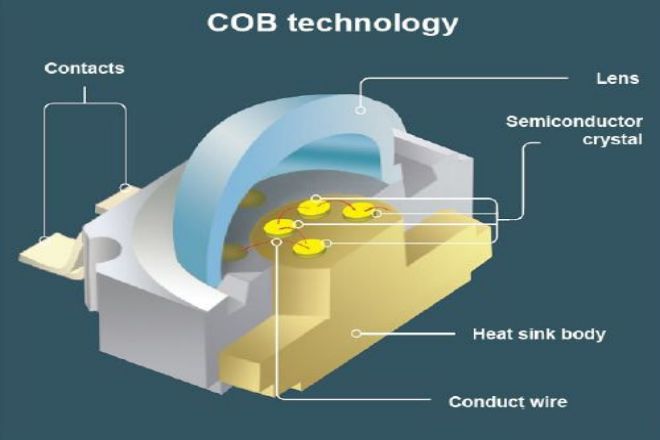

1). COB packaging (Chip on Board)

Definition: COB packaging is to directly attach multiple LED chips to a substrate and encapsulate the entire COB module through packaging glue.

Features: It has the characteristics of small size, good heat dissipation, and high light efficiency. It is often used in car lights, outdoor lighting, and other fields.

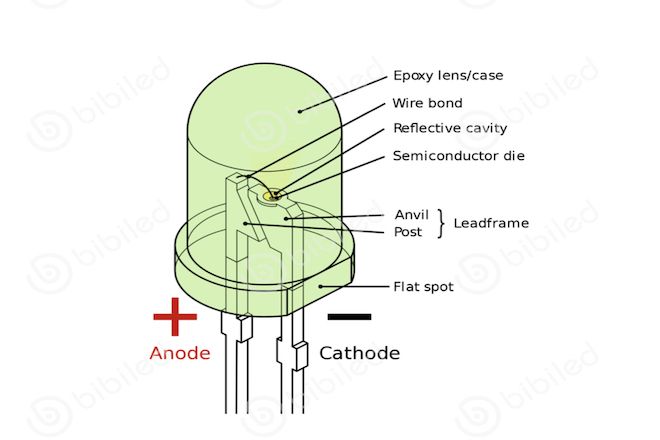

2). DIP package (Dual In-Line Package)

Definition: A DIP package is a kind of plug-in package. In the early days, red, green, and blue lights were inserted into the PCB to form an RGB pixel. Later, it developed into packaging the three RGB chips in one lamp bead.

Features: Good protection performance, but the viewing angle is not easy to accurately fix, suitable for outdoor large-pitch display screens.

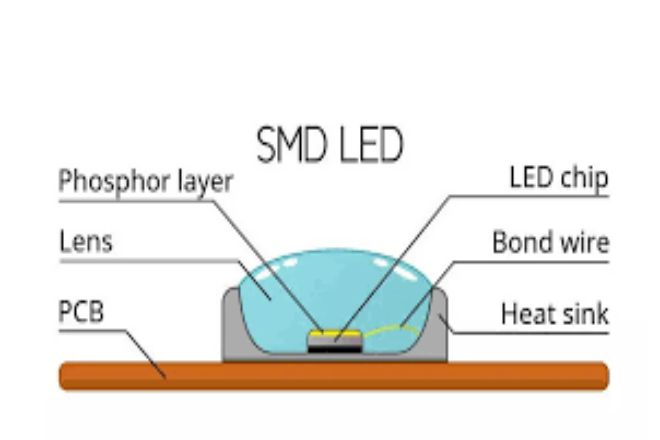

3). SMD package (Surface surface-mounted devices)

Definition: SMD package is a packaging method for surface mount devices, which is to directly solder LED lamp beads on the circuit board through surface mount technology.

Features: Mature and stable technology, low manufacturing cost, good heat dissipation effect, but low protection level, not suitable for harsh environments.

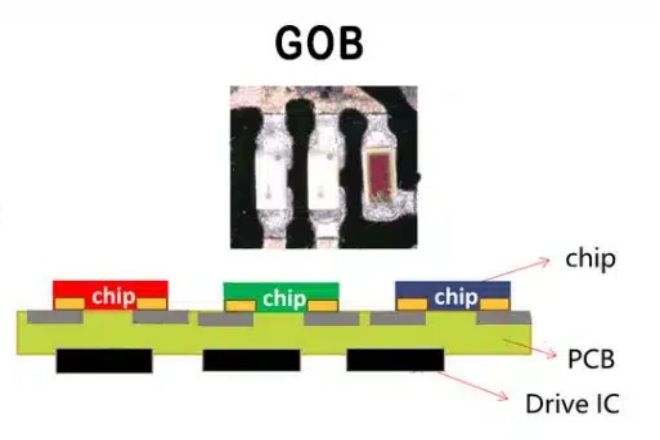

4). GOB package (Glue on Board)

Definition: GOB package is a new type of packaging technology that uses transparent materials to encapsulate the substrate and its LED packaging unit to form effective protection.

Features: It has high transparency, super thermal conductivity, can adapt to harsh environments, and realizes moisture and dustproof functions.

These packaging technologies have their own characteristics and are suitable for different application scenarios and needs. With the continuous development and innovation of LED technology, packaging technology is also constantly updated to meet the need for more efficient and energy-saving lighting.

5. Development trend of LED lamp bead packaging technology

The development trend of LED lamp bead packaging technology can be summarized as follows:

- Miniaturization:

LED packaging technology is constantly developing in the direction of miniaturization to further improve the pixel density and clarity of LED display screens.

Miniaturization has made the size of LED lamp beads continue to shrink, allowing more lamp beads to be placed in the same space, achieving higher resolution and more delicate display effects.

Miniaturization also brings higher integration and lower power consumption, which helps to improve the performance and competitiveness of LED products.

- Intelligence:

With the rapid development of the Internet of Things and artificial intelligence technologies, LED packaging technology is also evolving in the direction of intelligence.

Intelligent packaging technology will integrate more functions, such as temperature monitoring, brightness adjustment, remote control, etc., making LED products more intelligent, convenient, and controllable.

By integrating sensors and actuators, LED products can monitor environmental changes in real-time and automatically adjust the working status to achieve higher energy efficiency and longer service life.

- Green and environmental protection:

With the continuous improvement of environmental awareness, LED packaging technology is also focusing on the development of green environmental protection.

The use of environmentally friendly materials and processes to reduce pollution and energy consumption in the production process is one of the important development trends of LED packaging technology.

For example, the use of environmentally friendly materials such as halogen-free and lead-free, the use of green manufacturing processes and recycling technologies, etc., all help to achieve the green environmental protection goals of LED products.

- Customization:

With the diversification and personalization of market demand, LED packaging technology is also developing in the direction of customization.

According to the needs and application scenarios of different customers, customized LED lamp bead packaging solutions are provided to meet the personalized needs of different customers.

Customized packaging technology will pay more attention to product design innovation and differentiation to meet the diversified needs of the market.

In addition, LED packaging technology also has the following development trends:

High efficiency: High-efficiency LED packaging technology can provide higher luminous flux and brightness while reducing energy consumption and heat generation so that LED products have a wider application prospect in the field of lighting.

Integration: The integrated development of packaging technology not only improves the integration and reliability of LED products but also reduces manufacturing costs and promotes the rapid development of the industry.

Application of new materials: The use of new materials with higher and better environmental tolerance, such as high-temperature resistance, UV resistance, and low water absorption, such as thermosetting materials EMC, thermoplastic PCT, modified PPA, and ceramic-like plastics, will further improve the performance of LED packaging technology.

Conclusion

In summary, the LED display lamp bead packaging technology is a complex and critical process, which directly affects the performance and quality of the LED display.

With the continuous advancement of science and technology, packaging technology is also constantly developing, and trends such as miniaturization, intelligence, green environmental protection, and customization will become the future development direction.

Finally, if you want to know more about LED displays, please get in touch with us.